How to Simplify Your Output Generation Workflow

Table of Contents

You’ve completed an exhausting PCB design. The project is done, right? Not at all; it simply is an intermediate point before the product enters fabrication and assembly into the final product. Handing the design to manufacturing can be a significant part of the project itself. Organizing, assembling, fabrication, and ensuring a functional user interface are all top priority. How can you simplify this time-consuming process while ensuring your board gets manufactured right the first time? What is the best sequencing? How can you simplify output generation workflow? Read on!

Output Generation - What Your Manufacturer Needs

The typical files required are the Bill of Materials (BOM), Gerber files, NC drill files, ODB++ files, IPC-2581 files, pick and place files, and assembly drawings. Other items may be added to or removed from this list, depending on the fabrication and assembly requirements. It’s also not uncommon for the board fabrication house to request new data or additional data from the PCB after initial submission.

That’s why it’s important to establish a consistent workflow, so that it is easy to locate, organize, and assemble the required documentation. Standardizing on a particular workflow, or at least having a standard starting point for data generation facilitates a less painful post-design process.

Standardizing Your Outputs

Altium Designer provides tools and automation to produce and control all data and documents for fabrication and assembly. These tools make the job much less painful and helps assure that no errors are introduced.

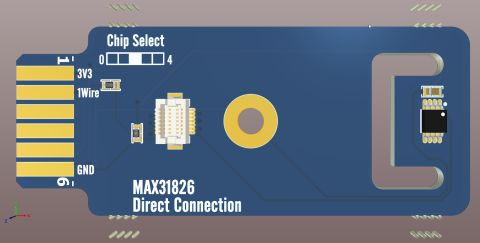

An Output Job Configuration file (*.Outjob) can be added to any project and becomes the one source where all required outputs can be generated. Output file types include Netlist, documentation, assembly, fabrication, report, validation, and export outputs.

You can setup an Output Job Configuration file that has all the required outputs ready for generation. In the figure below, this standard Outjob has been configured to include several outputs. It is shown in a ready status to generate a Pick and Place file, a Test Point Report, a set of Gerber files, a set of NC Drill files, and a BOM. Any other required files can be added or removed as desired.

Configuring and Reusing Outputs

Many of the delays involved with the PCB design to manufacturing process can be avoided with accurate data and documented notes for fabrication and assembly. Following these workflow steps is key! In addition, easily reproducing the required data can be a huge time saver for communication between PCB and fabricator.

Download a free white paper to learn about one of the best features of the output job file - reuse for multiple projects.