How Data Integrations Improve Supply Chain Performance

In the electronic components industry, efficient and resilient supply chain management requires precision and advanced strategies. Digitalization has revolutionized this field, underscoring the importance of data-driven decision-making to improve visibility, agility, and optimization. Discover how data integrations can elevate your supply chain performance through real-time insights, enhanced transparency, and enriched component data.

Challenges of Manual Part Data Searches

For many procurement teams within the electronic components industry, Microsoft Excel remains the primary tool for managing vast amounts of purchasing data. However, the complexity and volume of information required to be tracked far exceed the efficiency with which users can handle it within Excel. The procurement process for electronic components is inherently comparative, necessitating the evaluation of:

- Availability

- Prices

- Lead times

- Vendor reliability across multiple suppliers

This comparison is crucial to securing the best possible deal for the required stock, yet it often translates into hours of manual research for each purchase of a specific component type.

Once this critical information is gathered, it's typically entered into Excel spreadsheets for future reference. However, the electronic component supply chain is notoriously volatile, with market conditions and other disruptions leading to frequent changes. This necessitates regular updates to the data, adding to the already time-consuming task of data management.

Moreover, the manual entry of data is inherently prone to errors, leading to outdated or inaccurate information that complicates the purchasing process further. The time and effort spent in these manual processes divert valuable resources away from strategic activities, highlighting a critical area for improvement in supply chain performance.

What Is Meant by Data Integration?

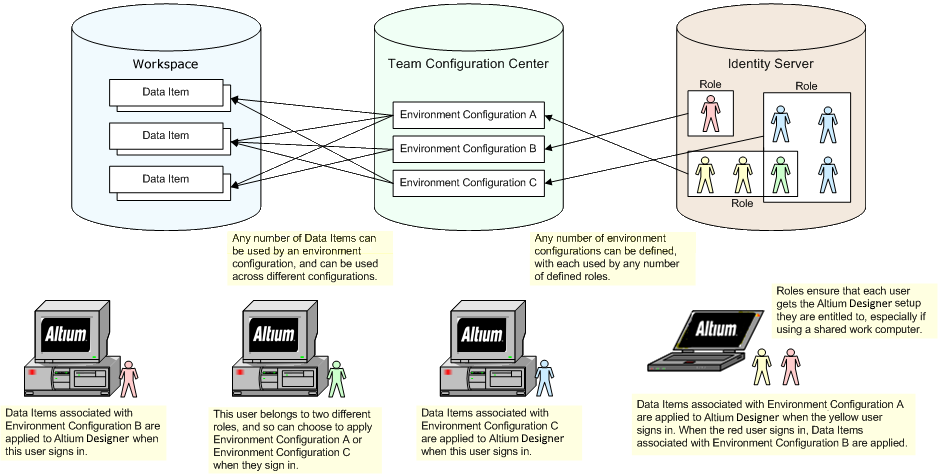

In the context of electronic parts supply chain management, data integration is the process of consolidating component data from diverse sources into a single location. This approach is designed to create a comprehensive view of information, enabling a clearer understanding of its collective impact.

Role of Data Integrations

Data integrations are crucial for digitizing and automating procurement processes, centralizing data across systems for easy access by all relevant stakeholders, and improving data quality via automated validation and enrichment. They contribute to building a supply chain that is agile, resilient, and capable of adapting to market changes.

However, despite the clear advantages, a study conducted by ToolsGroup and Spinnaker shows that a mere 7% of companies are currently harnessing the benefits of supply chain digitalization. This finding highlights a significant gap between the potential of digital technologies and their actual application across industries.

Example of Data Integrations

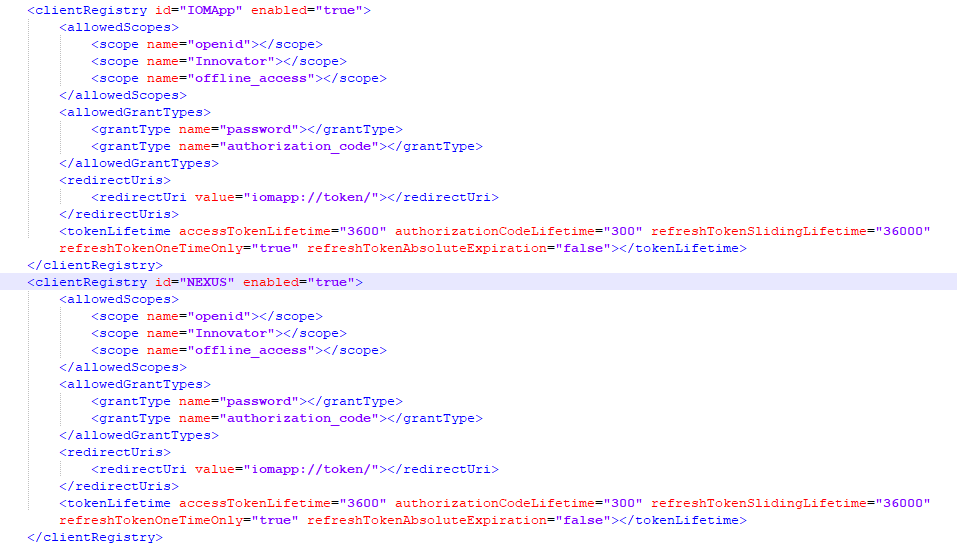

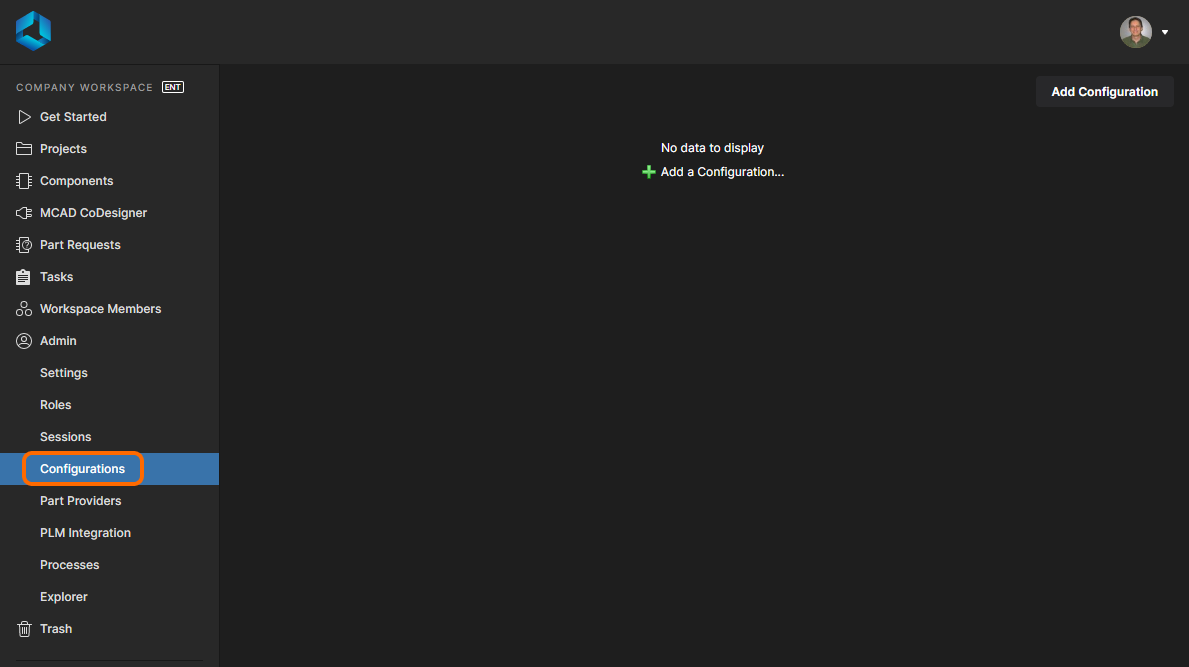

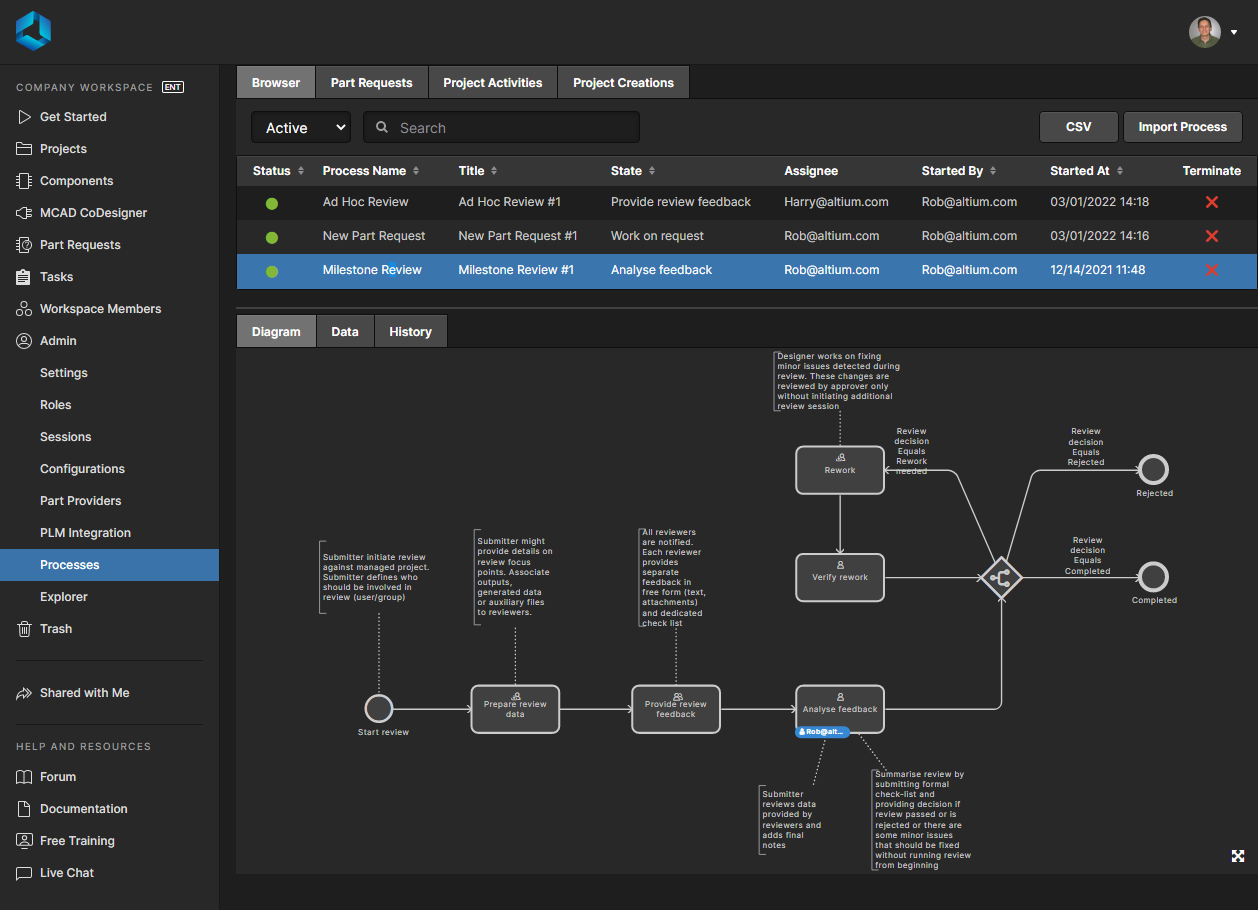

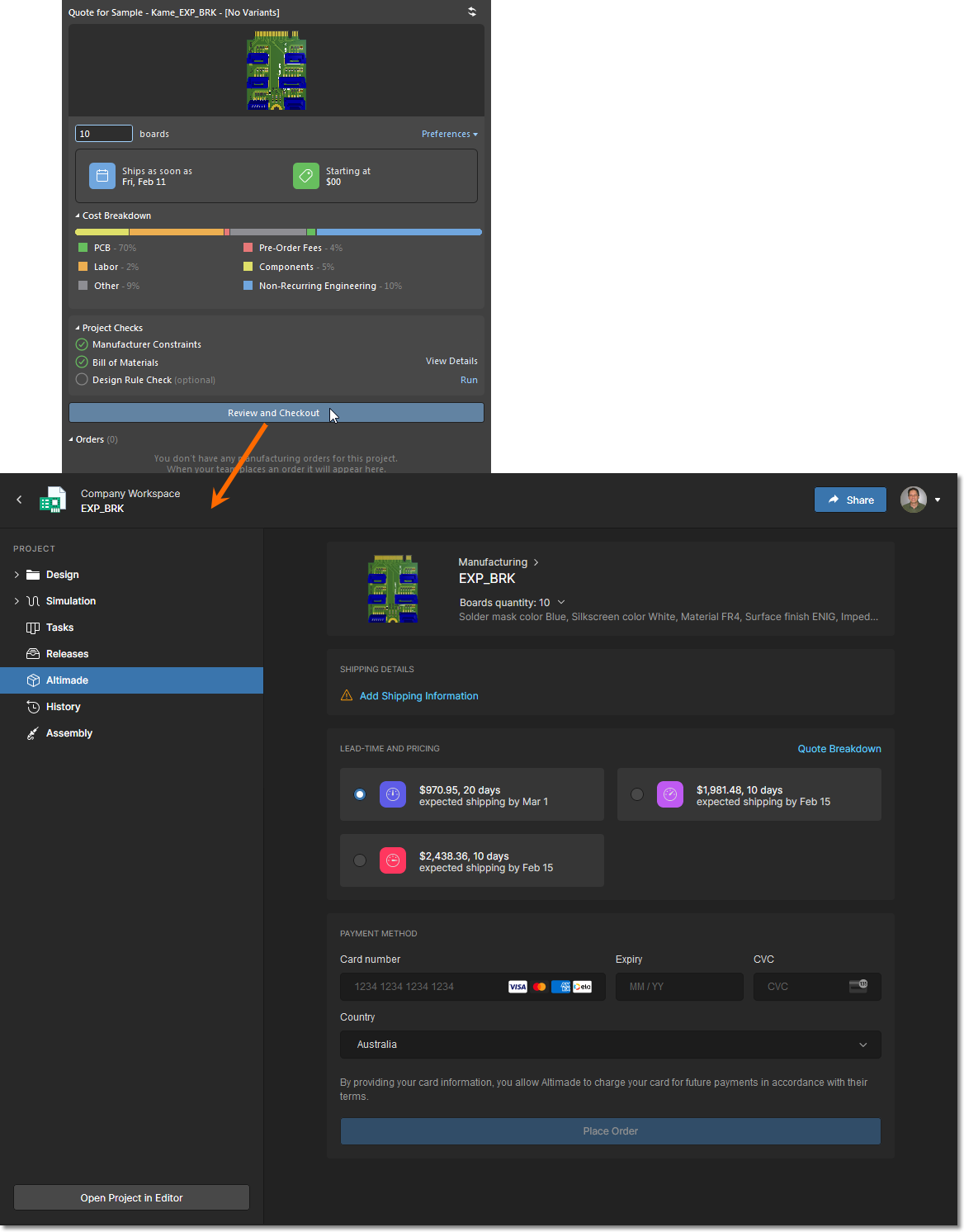

How do data integrations look in practice? Let’s take as an example Altium 365, a cloud-based platform for electronic product development. Altium 365 can serve as a central hub for aggregating crucial component data from multiple data sources such as Octopart, IHS Markit, SiliconExpert, and Z2Data (soon). These integrations allow you to access up-to-date information on component availability, pricing, and specifications directly within your design environment. You can make informed decisions about component sourcing and design modifications without ever leaving the platform, accelerating the design-to-manufacturing process.

What Are the Advantages of Data Integrations for Supply Chain?

Data integrations effectively solve the challenge of handling data from multiple providers. Previously, this data was buried in siloed systems. Today, data integrations enable a smooth flow of information, breaking down collaboration barriers and improving supply chain performance.

- Enhanced Supply Chain Visibility: Data integrations significantly improve supply chain visibility by providing access to real-time data on inventory levels, order statuses, and production schedules. This transparency allows businesses to monitor performance continuously, anticipate potential disruptions, and adjust proactively, thereby enhancing risk management and decision-making capabilities.

- Data-Driven Decision-Making and Faster Time-to-Market: Integrating data into your design environment and processes eliminates the confusion of multiple "versions of the truth" across different departments. With a unified view, decision-makers can access a single source of truth, accelerating the decision-making process. This real-time overview facilitates quicker product launches and more agile responses to market dynamics, ensuring a faster time-to-market.

- Improved Data Quality: Data integrations enhance supply chain data quality by automating data transfer and validation, reducing manual entry errors. This includes ensuring all part specifications and compliance information are accurate and up-to-date.

- Better Collaboration: Consolidating data sources breaks down barriers between departments and suppliers, fostering better communication. This enhanced collaboration leads to more effective decision-making and problem-solving across product development, accelerating lead times.

- Cost Reduction: By automating processes and optimizing inventory management, data integrations help reduce operational costs. Companies can minimize holding costs, lower transportation expenses, and reduce labor costs associated with manual data handling.

- Enhanced Compliance: Data integrations minimize human error and ensure accuracy, which is crucial for compliance and avoiding legal issues. They offer real-time compliance data visibility and centralized data management, simplifying the enforcement of uniform governance policies and security measures across the supply chain.

- Increased Supply Chain Resilience: Integrating data sources enhances the agility of supply chains, enabling organizations to quickly identify vulnerabilities and adapt to disruptions in the electronics component market, making the supply chain more robust against external shocks.

How to Integrate Data From Different Sources?

Understanding the potential benefits, you know the game is worth a try. Yet, a report from McKinsey and Company reveals that about 70% of digital transformation initiatives fail. The main reason? A lack of clear objectives and a too-general approach to adopting digital technologies. So, how do you make sure your data integration efforts succeed and avoid being part of this statistic? Consider the following guidelines.

#1 Define Your Objectives and Needs

Begin by identifying what you aim to accomplish through data integrations within your electronic components supply chain. A precise understanding of your objectives will help you sidestep the accumulation of redundant tools, simplifying your operations and cutting subscription costs. This clarity ensures you focus on developing processes that offer real insights and value to your workflows.

#2 Select the Right Platform and Integrations

Choose tools that align with your specific requirements, considering both the functionality and the implementation process. The right platforms will not only meet your current needs but also scale with your business.

Focus on the ease of use, compatibility with existing systems, and the ability to handle the data types you work with. Security should be a top consideration, so choose platforms offering robust data protection to safeguard your data's integrity throughout product development. Utilize Application Programming Interfaces (APIs) for a secure and efficient integration of different systems. APIs enable a safe, real-time data flow, keeping your supply chain updated with the latest and most relevant information without compromising security.

#3 Invest in Training and Change Management

The success of consolidating parts data within your electronic components supply chain also depends on your team's readiness to adapt to new technologies. Invest in comprehensive training initiatives and change management strategies to ease the transition, reduce resistance, and empower teams to fully utilize the capabilities of the integrated systems.

#4 Analyze Vendor Support

Choose solutions backed by strong vendor support. Expert guidance from service suppliers can fast-track technology adoption and sidestep pitfalls. Responsive technical support ensures swift issue resolution and minimal downtime. Vendors providing ongoing training and resources help teams stay adept with system updates and features. Tailored customization means your solutions fit your supply chain's unique needs, boosting efficiency.

#5 Monitor, Evaluate, and Optimize

Once implemented, continuously monitor the performance of your system and data integrations against your objectives. Collect feedback from users, and be prepared to make adjustments as needed. This iterative process will help you optimize your workflows over time.

Embrace Data Integrations for Procurement Excellence

Consolidating your parts data is crucial for success in the complex and competitive landscape of the electronic components supply chain. Take a moment to evaluate your existing processes and consider the advantages data integrations could bring to your procurement operations. The path to a more transparent and efficient supply chain starts with understanding how centralized and current information can transform your workflows, leading to enhanced efficiency, agility, and resilience.

If you’re ready to take the next step, explore Altium 365 data integrations and experience firsthand how integrating parts data can refine your design-to-manufacturing process, paving the way for smoother operations and better outcomes. Choose a more straightforward and faster approach to consolidating your data, accelerating the steps outlined above.