Intro EMC: Compliance, Opportunities & Pitfalls with Anton Tishchenko

On this episode of the OnTrack Podcast, Tech Consultant Zach Peterson welcomes Anton Tishchenko, aka Dr. EMC on YouTube. The two explore the intricacies of EMC design, certification, and compliance.

They chat about various aspects of EMC testing, common mistakes in PCB design, AI-integration, and how modules and antennas play a huge role in EMC compliance. Anton also shares his journey into EMC, how to approach design testing effectively, and insights into his fascinating PhD research.

Listen to the Episode

Watch the Episode

Key Highlights

- Strategies for effective EMC compliance

- Common mistakes in PCB design and how to avoid them

- The role of AI in PCB design checks

- EMC testing has a 50% failure rate on first attempts.

- Comprehensive design strategies can prevent costly EMC failures.

- Modules and antenna setups can greatly impact EMC compliance.

More Resources

- Learn More about Anton's PCB Tool

- Connect with Anton on LinkedIn

- Check Out the Dr. EMC YouTube Channel

- Anton's university page

- Exclusive 15 Days Free Altium Designer Access

Transcript:

Zach Peterson: I see so many people just default to like an ESP 32. They'll just go for a module, right? 'cause the module is pre-certified. And so then they'll just say, oh, well, you know, I'm using a module. I don't have to worry about anything else.

Anton Tishchenko: Well, yeah, no,

Zach Peterson: I mean, I, I agree that there was, you know, there was one design review video where that I did, where I'm just like, oh look, it's another ESP 32. And

Anton Tishchenko: There still, there's like a lot of tests still you have to do, such as SP emissions. For example, if you place this module with an antenna somewhere, that's actually another great point, but I'll get to it. And first of all is like, does the enclosure, how does that going? How is that going to affect the antenna because it, the radio signals can easily bounce off the enclosure and create like some spurious spikes that you didn't expect.

Zach Peterson:: Hello everyone and welcome to the Altium OnTrack podcast. Today we are speaking with Anton Chenko, who is better known as Doctor EMC, and the founder of P CCB for emc.com. I'm your host, Zach Peterson, and this is something I am very excited to talk about because it's one of the areas I have tried to make it my mission to learn much more about. So this is gonna be an exciting conversation. Anton, thank you so much for joining us today.

Anton Tishchenko: Thank you for invitation, Zach. My pleasure to be here. Yes, like, like Z Chen, I'm the founder of DR. EMC YouTube channel and also developer of PCB for EMC website, which is aiming to kind of analyze PCBs for mistakes and do some AI algorithms.

Zach Peterson: Yeah, that's funny you bring up the AI aspect because you know, I feel like everything we talk about these days has had AI infused into it. It's almost like we're in the, we're late, we're in the late

Zach Peterson: Nineties and

Zach Peterson: We're in the late nineties and everything has to talk about internet and now we're doing

Anton Tishchenko: Ai. Yeah. So yeah, well it is been mentioned that there are also different definitions of ai and what I'm kind of doing is not strictly the most intelligent, artificial intelligent way of doing things. It doesn't involve machine learning, it's more of algorithm for checks of basic design mistakes. So, which you can make on the PCB, such as the ground planes. Like we talk a lot about this, so usually when we do design reviews and PCB designs and yeah, this is something you can just check by analyzing the design files from like Gerber viewer or OGB plus plus this kind of analysis you can easily perform. So it doesn't really involve learning as such from artificial intelligence point of view, but it still kind of is intelligent artificially because you're doing it automatically and you're not, there isn't a manual person who's doing this work.

Zach Peterson: Yeah, well I, you know, with AI there has to be some sort of benchmark, I guess to which the, the designs are being compared. Right. And I think it's interesting because, you know, in PCB design we rely so much on rules. So it's always like a rules-based checking. So, you know, it's one thing to like say we're gonna compare, you know, these Gerber photo plots to 10,000 other Gerber photo plots and then decide pass fail. But I think when you have, you know, a rules based thing, to me it's a little more abstract how you actually build that data set and then set up a system that can automatically compare your test PCB with these rules.

Anton Tishchenko: Yeah, precisely. And the issue is like, oh, sorry, the issue with design rules in PCB layouts is they're only as good as you set them. Right? And if you didn't set your design rules

Zach Peterson: Yeah, yeah, exactly. You could follow the rules and it's the wrong rules.

Anton Tishchenko: So yeah, this is what we keep in the background. So in our case, we kind of like, this is under the hood of the tool is how exactly it determines what's, what is acceptable, what is not acceptable. But the aim of this tool, which is still a bit under development, is to give you an indicator. So it's not gonna say pass or fail, a lot of people would love that, but it can't really like substitute the real measurement and the real test. It's gonna be more of like, have you follow the best design practice for EMC? And,

Zach Peterson: And I think it's always nice for maybe, you know, people who aren't EMC experts who follow these kinds of tools to get like a recommendation for a fix.

Anton Tishchenko: Yeah, - Yeah. Maybe it gives them a path forward. So it, I think the best feedback is not just this is wrong, but here's here's the potential fix for this.

Zach Peterson: Yeah. I think I also, like I watched a few of your one minute design reviews, and I mean, correct me if I'm wrong, but design mistakes are always the same, aren't they?

Anton Tishchenko: I would say that there are some reasonably common mistakes.

Zach Peterson: Yeah.

Anton Tishchenko: Yeah.

Zach Peterson: So this is a sort of thing I'm thinking of development developing is this time it will just tell you like, is this design look, does this design look like it's a good design for EMC or is it gonna fail in every possible imaginable way because you haven't got the ground plane or something like yeah, it is to spot those big, big issues. And it is like, what is it, 20% of design is giving you 80% of results usually. So it's trying to hit that and make sure we capture all the big mistakes. But it's always like, whenever I've like worked with design, like for client when it's always something simple, it's annoyingly like when you have a pc like EMC failure, you'd like, sometimes you'd like something complicated to analyze, to debug, to calculate. No, never. It's always someone connected the chassis to ground or like forgot to add transient voltage suppressors or like no ground planes and yeah, it's always this kind of stuff that tricks people up somehow.

Anton Tishchenko: You, you know, that's funny you bring that up with clients because I, I talked a little bit about this with, with Eric Bogin on, on an episode that I think a couple years ago, and one thing that I had mentioned was that u usually when a company has failed EMC and they start looking for outside help, they've probably gone through at least one round of testing. They've probably gone through multiple rounds of pre-compliance and they're just, they have no idea. So they're probably ready to try anything. Hmm. And so they just throw everything they can think of at the design. They just, you know, stitching via is more ground, ground poor everywhere.

Zach Peterson: Yeah. Shield everything. Yeah,

Anton Tishchenko:Yeah, exactly.

Zach Peterson: Free times. Yeah. They just,

Anton Tishchenko: They just wanna try everything because I think it's a lot cheaper to try everything and take something off rather than go through another prototype spin with each solution iteratively and it end up, it ends up being a pretty substantial change to the layout, but I think there's usually that one simple thing that's really the root cause. Yeah. And if they don't know, they're just going to end up doing a, a lot of work on the design in order to, to get all those solutions in there.

Zach Peterson: Yeah. So if if it's radiated emissions failure, then that means there's a, a pretty good antenna somewhere on A PCB that they don't know of. And basically it, it's either it's in a cable or it's in a, like an inductor and all it takes is just to find it. But yeah, because they don't want to find it. They just put a mental enclosure around it and try to like isolate it for a day, cage it as much as possible and yeah, just some, some of those A MC fixes insane

Anton Tishchenko: Put put common mode chokes on everything.

Zach Peterson: Yeah. Right. Because I don't know what they're putting it on. They put it everywhere, like,

Anton Tishchenko: Right. Right. So one thing I wanted to ask you is, you know, how does someone who's younger like yourself get into EMC? And the reason I ask that is because a lot of the folks who I know who do EMC consulting, you know, EMC courses, you know, that kind of thing, they all have gray hair, let's say.

Zach Peterson: Yeah. I think I will do as well soon, but Yeah, it's, it's a good question. I, I, I think I've started because I had to, because we had a lot of products that have designed for audio. So I started off as a kind of audio product designer and we just needed to get them done. And there wasn't anyone else who knew or had interest of really working on this aspect of design. So, but then, like I think at some point I attended EMC course taught by Lee Hill, he's one of the legends with silent solutions and I really enjoyed that course and I think it is inspired me to do more research on this area. And yeah, it's just came kind of naturally and also like now, I dunno if you're aware, I'm also doing a PhD, I'm in the final stages of my third year and basically it comes hand in hand with all the research I'm doing with electromagnetics and I'm designing antennas for six G. So kind of interesting concept, right? So yeah, it, it kind of helps to understand what electromagnetic propagation is like of real devices. And I, I see a lot of researchers actually lack that knowledge.

Anton Tishchenko: Interesting. Interesting. One, one thing I point out to the, to the EEMI folks is, is you know, the correspondence between SIPI and EMI because they all kind of wrap together and sometimes your SI problem is really the root of your EMI problem. Oh yeah.

Zach Peterson: Well, what could argue that the tool that I described is really a SI tool and it's a valid argument.

Anton Tishchenko: Yeah. I'm, I'm surprised how, how many of those guys is experienced and knowledgeable in EMC as they are, you know, the SI correspondence is is maybe they're not so well practiced in IT because I think they spend so much time on testing.

Zach Peterson: Yeah, well, si what do depends on what we mean about SI a lot of it goes into the simulation tools for SI and I think it's quite like, typically when it's simulated, well it's not gonna have a lot of EMC issues either, but the, the issues normally come from products that haven't been simulated for SI at all. And Yeah. And the company obviously doesn't have a budget to do it, so you can't, you can of, can't sell them a 30 grand subscription to Ansys or something and They just laugh at you if you try. And so what do they do? And yeah, this is then they usually just go to a test house, fail it once, and then learn from it and try better next time. That's what normally happens. This is why we, we kind of com there's like, I, I stole this line from somewhere, but it is pretty much a 50% failure rate on the EMC testing for the first time. That's, I think is accurate. Like 50% of products that go into EMC test houses fail. And they obviously that seems like a lot a loss, but is again, to EMC test houses, it's good for them.

Anton Tishchenko: Yeah. This is a good justification for maybe for young people to pursue EMC as a career because you know, as I mentioned, you know, the current group of EMC experts obviously being grayer than us are gonna retire at some point. But 50% failure rate, I mean that's a, that's a crazy failure rate.

Zach Peterson: You say 10 industry and yeah. Have different effects, but somehow it came to like, I dunno, in, at least in the uk it's to the point of almost acceptance, it is like this, some companies, they would just plan for an EMC failure in their schedule. Like, you know, they don't even assume that you're gonna pass, they assume you're gonna fail. And then it's just, it's a bit demotivating. Like, because well why, why you don't, you don't trust me or something.

Anton Tishchenko: It, it's, it's funny because I I'm sure they probably don't even call it an EMC failure in their budget. They just call it a round of Yeah,

Zach Peterson: Yeah. Second round, second round of testing. Yeah. Well why do you need second round of testing if you didn't fail?

Anton Tishchenko: Exactly. Yeah, that's a good point.

Zach Peterson: So yeah. And it's very often is in the budget on a very high level and yeah. Yeah. Why, why can't we do something about it?

Anton Tishchenko:You know? And, and you brought up simulation tools and I think it's easy for those of us who have experience with simulation tools to just say, oh, just get a simulation tool. But oh yeah,

Zach Peterson: I, I see it in a university. I get all the subscriptions for free, like, you know, and Ansys, CST and you know, they call us all the time and they are, they offer, would you like this? Would you like that? You know, please. Yeah. But yeah, if you go to the industry and it's like you discover the prices, you just go like, oh my god, really?

Anton Tishchenko: Well, not only that, but like the, the, the knowledge needed effectively

Zach Peterson: And you need to know how to run them effectively. Yeah, yeah,

Anton Tishchenko: Yeah. You, you need a, you need somebody who is a, a simulation expert has that

Zach Peterson: Yeah. It's a full-time job, effectively.

Anton Tishchenko: Exactly. Yeah. Has that master's or or PhD level, you know, background knowledge about all the math that's going on to even get accurate results.

Zach Peterson: Yeah. It's quite challenging and yeah. Very unattractive for like startups. Startups wouldn't even think or dream of doing something like that.

Anton Tishchenko: Yeah. That Oh yeah, that's true. Yeah. So I'm, I'm eager to see what some of those, you know, AI based simulation tools can uncover. 'cause you know, like you said, I think if it can pick out the, you know, one or two things that would, that are simple, right? They're simple design changes, but they can lead to that EMC failure. Mm. That's a huge, huge savings in the budget. Yeah. It's almost, it's a good insurance policy if you ask me.

Zach Peterson: Yeah, I think, I think that's definitely the plan and the, one of the issues as is that IP rights, a lot of companies don't feel comfortable about sharing their design. It's, it's a very simple idea, you know, you just get someone who's experienced to look at your design and they, you know, pretty much tell you straight away if it's something wrong, you know, you only need one minute for yours. So,

Anton Tishchenko: Well, I, I spend, I spend more than a minute preparing

Zach Peterson: It takes longer hard to condense to make, yeah,

Anton Tishchenko:Yeah. It's hard to condense stuff down to one minute sometimes.

Zach Peterson: Well, so, but still, like it's possible to do that and but many companies like defense companies, they wouldn't wanna do that. They would like, and this is a challenge, obviously, they're very strict with even sharing their fabrication files to fabricators. They always sign NDAs with every fabrication house. So yeah, this is, I don't really have a solution for it as much, but I highlight it as a potential problem that people should be aware of, I guess. And one of the reasons why it is how it is because traditionally companies don't like other people looking at their things and for good reasons. So yeah. That's why we can't just, you know, send a design to someone to have a look at and, but yeah. Yeah. Yeah. I I'm hoping that if it's, if if it's just a neutral tool, like artificial tool and you just, and it doesn't store any data, then maybe I can convince people to use it, but we'll see how it goes.

Anton Tishchenko: Yeah. You know, and, and you brought up, you know, aerospace and defense. I mean, I think if there was a desktop version of it because

Zach Peterson: Yeah, like desktop, all those services, desktop, yeah.

Anton Tishchenko: Oh yeah. All, all those services, you know, people try to make 'em cloud based and that really crowds out the most, the, the highest corners of the market and your potential user base. And it's, it's funny because I, I talk to, I, I talk to VCs and stuff who, you know, they want investment advice and you know, depending on companies and stuff like that, they're looking to invest and a lot of 'em queue into hardware companies and, and they just don't seem to get why people don't want to use a cloud service a lot of the time. And it's for the exact reason you brought up

Zach Peterson: Yeah. It's not as secure, is it?

Anton Tishchenko: Yeah,

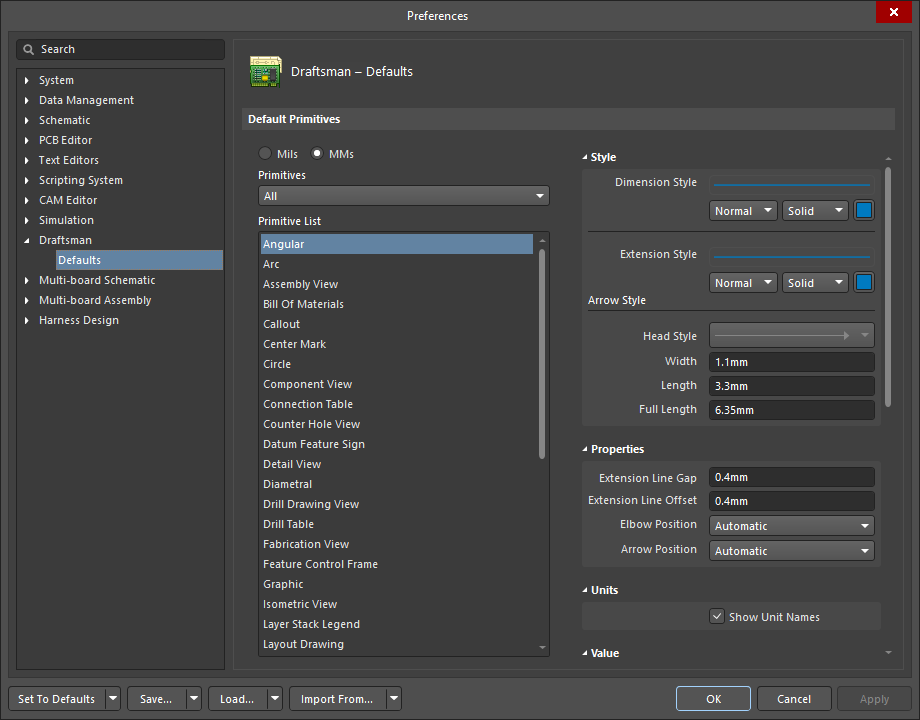

Zach Peterson: Exactly. Yes, definitely. Like desk tool or even like, because you have plugins as well in your PCB design tools such as Kai Card or Altium Designer. You can install a plugin and it could be that.

Anton Tishchenko: Yeah, the plug, the plugin idea is great. I mean, you, you know, for, for the, the non LTM users out there who might be listening, if, if you look in Altium in the extension section, there's, there's this big list of, of additional extensions and integrations and it's actually really cool that you can do that in the design tool. By the

Zach Peterson: Way, I, I saw you used on your recent video the says one one analysis. How did you make that up? Was that part of ultium or It was done completely externally.

Anton Tishchenko: So that was done with sym.

Zach Peterson: Oh, okay.

Anton Tishchenko: Yeah. But you know that that's another in, it's not a direct integration, but what's nice is that you can do an export, like for example, from a stack up into Symbio format. Yeah. And then just really quickly import it or you can just output the ODB files.

Zach Peterson: How long did, did that take into the simulator take to output and put set up the simulator? How long did it take

Anton Tishchenko: For the fast SI simulator? Just a matter of minutes. It doesn't take very long. Yeah, okay. Yeah. It's not the full 3D simulation. Once you do the, you know, the full 3D simul simulation

Zach Peterson: Takes, - Don't need to, you know, a little bit longer but just to do the outputs and then import, it's pretty quick. So, 'cause it was quite

Anton Tishchenko: Impressive some Yeah. Because highlighted immediately all that, you have a lot of issues on that trace. Right. And it's a lot of reflections and things.

Zach Peterson: So they already do the sim, the, the signal integrity simulator in all team designer. They already do the, the calculation be se each section of the trace. So it's a pretty simple matter to just display the impedance values somewhere as like a heat map, you know? Yeah. You know, and you could do it with the Symbio STK. So it would be really interesting to see that as a feature ad and then do a direct export over to Symbi or for any further analysis or something like that. I think that would be really cool.

Anton Tishchenko: So the reason they didn't do it is because they don't have resources or why

Zach Peterson: No, I, I, I think they, I think fairly, they've been focusing a lot on the cloud deployments and things like that because, you know, it is pretty useful as far as you know, data management and then I'm sure there are enterprise customers that, that want that. So you could say it's limited resources. I mean I say it's attention placed elsewhere and I think it's fair, you know.

Anton Tishchenko: Right.

Zach Peterson: I think also, you know, if people knew that this was a thing that you can do but they don't see it, they would demand it more. But I think because people don't demand it more, it, it doesn't end up in the, in the new version, which is also fair. Right. I mean you try and be responsive to, to users.

Anton Tishchenko: Yeah. That's actually a good point is you raised is a awareness to EMC in it tends to be quite low in general among PCP designers, isn't it? It's just happens at the end of the project and then they kind of almost caught up by surprise that suddenly there's like all those requirements apparently apply.

Zach Peterson: Well I, I think that's where the rules of thumb come in and people try to rely on some really basic stuff with rules of thumb Mm. To then get around a consideration of some common stuff with

Anton Tishchenko: EMC. Yeah. But they don't work like, because if you have so many industries like aerospace, defense, railway, commercial and presidential, all that stuff, you can't apply one rule to everything. So this is a very common thing to, to, to experience is that you start with something and then as you apply those environmental things, you can't even like selecting cos parts. Like if you're just selecting something like a power supply and if this decision is made early on in a project, it becomes really difficult to change it later in a project when you suddenly discover that you need to apply some standard that this cos power supply just simply doesn't comply with. And what do you do then? So it is, yeah, that's what I mean by this aware awareness to e EMC is, yeah, it needs to be really, it does need to be designed into from the first meeting or from the first project requirement, specification iteration and yeah, it doesn't seem to happen. So maybe that's, that's why you don't get asked as much about it as you should be perhaps in terms of old term designer as well.

Zach Peterson: Yeah, I think that's fair. I think another aspect to that is that even if somebody does know it's important, sometimes the requirements as far as the standard that they need to operate under, they probably don't know which standard it is. Or if they do, they don't know what the requirements are in the standard. And there are some component manufacturers who are really good at stating specifically, if you do this, you will be compliant with this standard. Which is helpful. But I mean what percentage of components is that? Like for example, with brick power supplies, you know, is it 20% maybe, you know? Mm. It's kind of a shot in the dark as to whether or not the one that you pick that's actually gonna give you the performance is also gonna give you the EMC compliance.

Anton Tishchenko: Yeah, yeah. And for what industry? Yeah. So that's the other thing I I started doing is I started kind of compiling different industry specific knowledge into video courses. And so I've, the first video course I made is about radio. So when you have intentional transmitters in your product and so in in the US you need to apply FCC or regulations obviously. But in Europe we have a thing called Etsy, European, European Telecommunications Institute and they publish a lot of standards. So even though the standards are mostly different, they are mostly the same at the same time because they fall all kind of pursuing the same goal. So, and yeah, if we start looking at things like automotive electronic equipment, it will be a completely different group of standards and completely different group of tests like which often trips people up as well.

Zach Peterson: Yeah, I think that's a great point. Now one thing that you just brought up was radio and in order to I think get around having to even deal with radio standards, I see so many people just default to like an ESP 32, they'll just go for a module,

Anton Tishchenko: Right?

Zach Peterson: 'cause the module is pre-certified and so then they'll just say, oh, you know, I'm using a module, I don't have to worry about anything else.

Anton Tishchenko: Well, yeah, no,

Zach Peterson: I mean I agree that there was, you know, there was one design review video where that I did where I'm just like, oh look, it's another SP 32 and it's like they're, I think they're great learning tools, but like you can't rely on SP 32 for everything

Anton Tishchenko: And still there's like a lot of tests still you have to do, such as SP emissions for example, if you place this module with an antenna somewhere, that's actually another great point, but I'll get to it. And first of all is like, does the enclosure, how does that going, how is that going to affect the antenna because it, the radio signals can easily bounce off the enclosure and create like some spurious spikes that you didn't expect. So it's still like lots of testing you still have to do even, even if you select a module based approach. And yeah, so the other point is the antenna itself. Like, because if you didn't go with antenna, so what I like about FCC is that you can access every certification report online quite easily for like see compliance testing. A lot of folks never publish anything because it's, well very often they don't do any testing and they would just sign off A DOC and keep it to themselves. But the point is that you don't have to publish it. There's no law that requires you to publish it. Whereas with FCC it's really good because it requires you to have this publication uploaded into the FCC. So all the FCC reports are available online and you can see what antenna had been used, what the configurations been used, what the test setup was, everything. And typically the recommendation is that when you buy a module, you need to use the same antenna that has been the used during the testing and then you can kind of mostly assume compatibility. But what if you don't? So like if you, if you specify a different antenna which like instead of 2D BI gain, it has six DBI gain, where does that put you with the regulations in terms of EMF assessment with the spurious emissions assessment with the TR T-R-P-T-I-S assessments? So basically you have to do everything again, isn't it? Because you can't just assume that is going to comply now because you have a completely different antenna. The radiation pattern is completely different. Again, it's different and you need to repeat all the measurements. So it doesn't always simplify things actually

Zach Peterson: Yeah, module module certification only gets you so far.

Anton Tishchenko: It only gets you so far. Exactly.

Zach Peterson: I I think, I think the other aspect of it, of it that is attractive is that you at least know the module antenna works if you just follow like a couple of rules.

Anton Tishchenko: Yeah. Functionally it's easier to design. Sure. What I've, what I've been recent now that might be interesting for readers to learn as well is was that there's a new thing in town called antenna chip and that becoming increasingly popular. And what I recently discovered is that you can't rely on antenna and chip in the same way as on a module because once you put your antenna chip on A PCB, it changes completely. Once again, you have to follow exactly the same PCB as been used during the assessment. So you need to kind of match the stack up, match the distance to the ground plane, match the size of the ground plane. And if you don't, you get a completely different performance.

Zach Peterson: Yeah, that's a good point. Especially with antenna on chip. 'cause going back to the module, you'll just see somebody, you know, overhang the antenna, you know, off the edge of the PCB or they'll do a cutout and for the most part, at least functionally it works, but then yeah, once you throw it onto a chip, that chip is then overground. There's a whole stackup that goes along with it. I think it totally changes everything.

Anton Tishchenko: Yeah. Yeah. And it does. Yeah. And it's, it comes as a shock to a lot of people.

Zach Peterson: Yeah. Yeah. I haven't used any antenna on chip yet, but I, I'd be interested to, to see how that works.

Anton Tishchenko: Yeah. Don't,

Zach Peterson: I'm sorry,

Anton Tishchenko: Don't,

Zach Peterson: Don't, that's fair. That's fair. Yeah. The, the, the closest I've gotten was antenna on module, but not like the, the meandering F antenna that you have or the, the meandering micros stripp antenna. They basically just have like a small, you know, ceramic that they put on there and then that's, that's your emitter. So you never see the antenna, but it's broadcasting and it's connecting to your wifi.

Anton Tishchenko: Right. - Yeah. Those modules are always fun to play with. So switching gears here to the EMC courses that you mentioned, you know, you mentioned radio. What are some of the other industry specific courses that you're focusing on?

Zach Peterson: Yeah, well I'm working out this automotive now next, so the next one is going to be about automotive electronic equipment and yeah, then on on the on I will also do railway. I think for sure this, it would be interesting to do medical because it's become really strict recently.

Anton Tishchenko: Yeah. Medical would be interesting. And that's, that's actually one of the, I think that's one of the areas that is very high value.

Zach Peterson: Hmm.

Anton Tishchenko: But very esoteric.

Zach Peterson: Yeah, yeah.

Anton Tishchenko: Compared to something like, you know, radio.

Zach Peterson: Yeah.

Anton Tishchenko: And then what about like, like mill spec

Zach Peterson: Mill? Yeah. That's also very interesting one, but I don't have quite as much experience with it though, so that's, yeah. It would be good to gain that experience first.

Anton Tishchenko: Yeah, yeah, of course. So one thing you also mentioned earlier was you are working on a PhD.

Zach Peterson: Mm. - If you could tell us a little bit about the research you're doing for your PhD.

Anton Tishchenko: Oh yeah, yeah, absolutely. So it's not really related to EMC, but I, I think maybe we should write a paper together about EMC. That would be cool. Haven't I've, I've never done any em mc papers. But yeah, on my current research basically is about what we call intelligent mirrors. So we, for six g we are proposing that we going to, instead of antennas, well not instead completely, but to supplement the antenna layout, we're also gonna have intelligent mirrors on surfaces implemented at various positions on a street or in a building or inside a building. And those will help to steer the radio signals from the base station to the user. And basically these can be either passive surfaces, so completely metallic and without any circuitry. Or they can be also active surfaces, which is all based on the theory of metamaterials. So they call, we call them meta surfaces. And so those passive and active meta surfaces is effectively what my research group is focusing on.

Zach Peterson: So just for myself and, and maybe for some other folks. When you say metas surface, I think this is a little abstract, I'm a little more familiar with the idea of metamaterials but not metas surfaces. My understanding is that it's precisely engineered geometry and materials or material properties in order to give you specific performance, let's say. Yeah, same idea with metas surfaces.

Anton Tishchenko: Yeah. Yeah. Metas surface is just a 2D version of meta material. So if, so basically it's just a planner thing instead of like original theory of metamaterial assumed that you have this 3D so you can absorb signal, reflect, refract, everything. Whereas with a 2D version, you only a bit more restricted. But we still do, we still can do quite a lot. So instead of making it volumetric, we just make it planner. And yeah, it also applies quite a lot. So I should mention to higher frequency ranges because it becomes more attractive for higher frequency ranges since those planner structures becomes smaller, or at least they don't necessarily become smaller, but the, the, it becomes easier to make them smaller if you wanted to. And you typically you do want to make them smaller. So to our, so for like a millimeter wave at 28 gigahertz, a structure would be of about this size. Whereas if we target 3.5 gigahertz and it's all related to wavelength, so if we target 3.5 gigahertz, it'll typically be at least one meter in the amateur. So basically it is a lot more space that it will take and it's not really cost efficient as much as it would be for millimeter wave. So again, retargeting mostly like future networks and not existing networks. But yeah, and we also envisioning this integrated sensing and communications for future networks where every position of the user will be known by default to the network. So we will be able to tailor our network resources accordingly and make those networks very energy efficient. Which is exactly the problem with the existing millimeter wave installations is that they're so power hungry that they basically, a few network operators tried to put millimeter wave base stations, but because they basically tried to radiate omnidirectionally, it just fails to work because it, it consumes huge amounts of power and it's just really terrible idea. So instead we kind of want to move to the point to point communication links with reconfigurable surfaces acting as a kind of interface between the base station and the user. That makes sense

Zach Peterson: A a bit. I I think I'm, you know, you mentioned that it's like a mirror prior. Yeah, okay. Usually when it, this is my optics background jumping in here and it's probably incorrect, but usually when someone says a mirror in the context of an emitter, it's almost like the mirror might be used as a focusing element.

Anton Tishchenko: So it's exactly what is, especially when you, in the near field of that mirror, it acts as a lens. So it, it, it it does exactly that. It focuses the radiated power on your user device. So, and I don't mean your head, I mean the smartphone.

Zach Peterson:Yeah. Right.

Anton Tishchenko: We, we want to be this precise, we want to focus it on the antenna, not on the, not on the people.

Zach Peterson: Right? Right. And so this would be compatible with, with analog digital hybrid beam forming all the standard beam forming methods.

Anton Tishchenko: Yeah. Because essentially the mirror is neutral, it shouldn't affect the channel at all. So yeah, it don't matter what BIM forming you're using at the base station.

Zach Peterson: Got it, got it. Okay. This is extremely interesting and hopefully you'll do a video on it in the future because

Anton Tishchenko: That type of stuff I have done one. Yeah.

Zach Peterson:Oh, you have done one.

Anton Tishchenko: But it is very introduction, but, but what I find frustrating with YouTube is that it doesn't really give you a lot of flexibility. Like if I, if I make a channel on EMC and then suddenly I make a video about six G doesn't like that.

Zach Peterson: Right, I see, I see.

Anton Tishchenko: It just doesn't advertise. It, it like, it, it really kills it. Like in in particular, I made a video about, not six G, but for example, ingress protection, you know, like water liquids and the dust and things like that. It should kind of related to EMC, but is more of a mechanical test. So more mechanical engineering and yeah, YouTube algorithm hated it. Like absolutely it killed it, it, it, it only showed it to 200 people, all of whom were my subscribers already. And that's it.

Zach Peterson:Unfortunate.

Anton Tishchenko: Yeah, it's, it's really quite tricky. Well, I'll try to find a way to link, like I'll try to find a way to link those things like reconfigurable surfaces and EMC maybe.

Zach Peterson: Well I, I would encourage anyone who is listening to check out our show notes and go subscribe to the channel and you'll be able to learn all about all this stuff with EMC. I know this is something that I have been trying to learn more about as well as manufacturing. And we've talked to a lot of manufacturers recently, especially folks more on the semiconductor side with packaging. But we've left out EMC, so I'm glad that you've been here with us today to talk about EMC stuff and hopefully some folks will go subscribe and learn.

Anton Tishchenko: Oh yeah, absolutely. Yeah, please visit my channel, Dr. EMC, and also have a look at PCB for EMC webpage. It's still on the develop, but there is a course you can purchase and there is also the page for the PCB analysis tool, but you can only subscribe to the mailing list for now. But once as soon as I get it finished, I'll notify you and let you know that it's available.

Zach Peterson:Excellent, excellent. We'll have links to all of that stuff in the show notes. Anton, thanks so much for being with us

Anton Tishchenko: Today. Thanks for invitation, Zach. Appreciate it so much

Zach Peterson: To everyone that's out there listening, we've been talking with Anton Chenko, better known as Dr. EMC and the founder of PCB for emc.com. If you are watching on YouTube, make sure to hit that like button, hit the subscribe button, and you'll be able to keep up with all of our podcast episodes and tutorials as they come out. And last but not least, don't stop learning, stay on track and we'll see you next time. Thanks everybody.