Designing to Meet a Target BOM Price and PCB Cost Estimate

Table of Contents

Creating an accurate PCB cost estimate for design, components, production, assembly, shipping, and even firmware can be a challenging task for new designers. Even established organizations can have trouble getting it right as it's hard to anticipate every problem that can arise during a design. Manufacturers can help you handle the production and assembly portion of a project, but any time a new design needs to be put into production, components will need to be sourced for the board and everyone will need to stay within a budget.

In days past, you'd have to call around to manufacturers to get component prices and stocks, and then you'd use these data to develop a PCB cost estimate. Having more detailed information up front, like the BOM price for components in your PCB, can save design teams plenty of time and reduce the risk of redesigns before production. Instead of relying on outdated BOM price data from vendors you’ve used in the past, there’s help in the form of a bill of materials and cost estimates management tools built right into your PCB design software. Here's how you can use these features and a cloud-connected design application to ensure you get accurate BOM prices and stay within your budget.

The Data You Need From Your Component Vendors

PCB design teams need a complete set of data to target PCB cost estimates and accurate BOM prices. This is just one part of the design and production planning process, but it can make a huge difference in budget and may eliminate the need for full turnkey services. Here is some of the data you'll need from component vendors or manufacturers:

- Price: Get the latest information on the price to make sure that the parts that you are using will cost what you expect them to.

- Availability: Make sure the parts in your design are in-stock and available for order.

- Lifecycle information: Designers should be able to instantly identify whether a component has gone obsolete, EOL, or is still in production.

- PCB footprint: Components that have updated CAD data and PCB footprints can cut down your design time.

- Price breaks: Volume discounts on the same or similar components can help keep a project within its production budget.

Engineering can get frustrating by the time a design needs to move into production because teams may suddenly find they can’t get the parts they need for their designs. As a result, they end up having to do major redesigns when they find critical components are unavailable. To prevent these headaches, designers need to get all the data listed above early during the design process, instead of getting costs and stocks right before production.

With a cloud connection to approved vendors provided by bill of materials management tools, a lot of this frustration around redesigns can be eliminated. In addition, it's easy to quickly see whether a project will fall within a production budget, target PCB cost estimate for finished boards, and put together an accurate BOM price. Designers can see these benefits when they can access the sourcing data directly in their PCB design software.

How to Design a Target BOM Price

If you haven’t had much experience in designing PCBs that have tight profit margins, it can be a real eye-opener. You may be used to creating prototypes, limited production runs, or unique application-specific boards where component pricing may not have been one of the primary concerns. When you start designing with price as a major consideration, you will find that saving a penny on every component will add up to important cost savings.

Part of developing a comprehensive PCB cost estimate is getting an accurate BOM price. Fabrication, assembly, and NRE costs need to be amortized across each unit produced, but these costs can be estimated by consulting with your manufacturer. This will then set an upper limit on your BOM price and your per-unit parts budget.

Here are some tips you can follow to design a target BOM price and create your PCB cost estimate:

- Choose critical ICs and processors first as these will determine how the rest of your system operates. If any of these are unavailable it's possible you'll need to do a redesign before production.

- Some components like transistors have many equivalents, so look for alternatives when these parts are out of stock, obsolete, or EOL.

- Consider consolidating parts like passives that might be found in series or parallel. This can help reduce costs if you're already far from a price break.

- You might be able to find components with higher absolute maximum ratings for a lower price and similar critical electrical characteristics as your first-choice components. Consider using these components if they can help you get a lower per-board BOM price.

Having the current component price available to you with the BOM management tools is an invaluable aid to cutting component costs on your final design. Being able to see the current costs of your components from your different approved manufacturers, as well as component alternatives, allow you to make circuit creation decisions that may ultimately reduce costs.

With BOM management tools available to you as you work, the tough job of designing your circuits in order to get the best component balance between performance and BOM price becomes a lot easier.

BOM Price at Your Fingertips in Your PCB Design Tools

The key to this level of help, where component information is available to you while you design your schematic and PCB layout, is in using BOM management tools within your PCB design software. You no longer need to wait while someone else in another department researches parts prices, stocks, and lifecycles to develop a PCB cost estimate and BOM price. You can also avoid last-minute redesigns when purchasing tells you that they can’t get the parts you were expecting to use.

Go through your BOM management tools and access complete component information on the parts that you want to use. The more details that you can get upfront on the components that you are working with will help you to complete the design knowing that the parts you are using are the best choices.

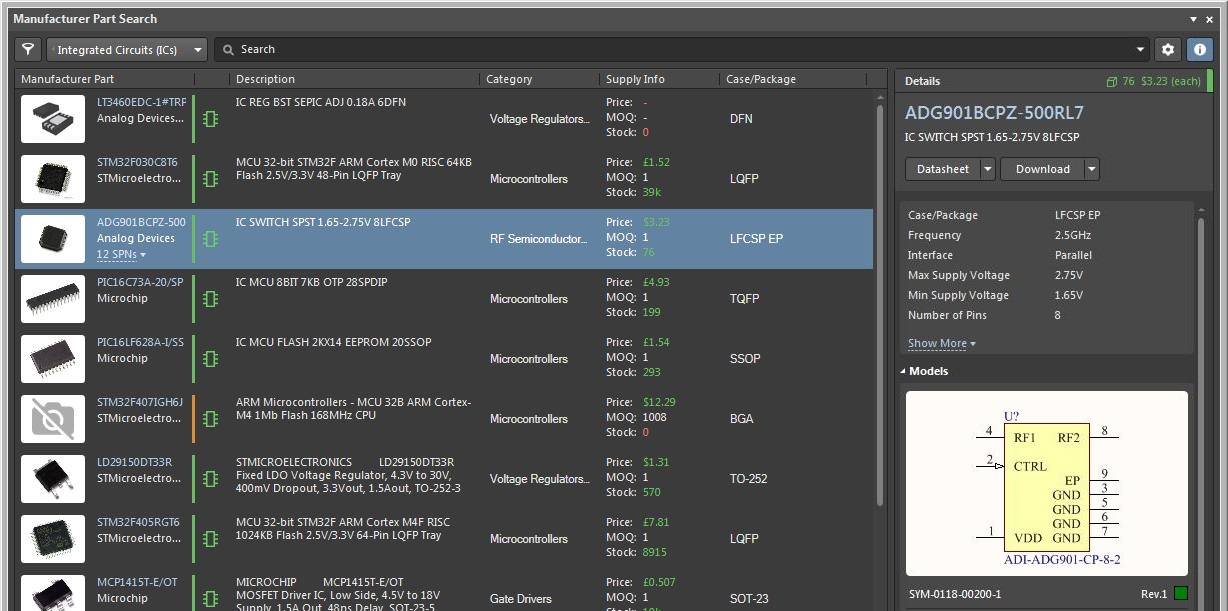

Altium Designer has the bill of materials and cost estimates of management tools you need to meet your PCB cost estimate and develop a component budget. The Active BOM utility and Manufacturer Part Search panel are much more than parts finders or report generators, they give you a direct view into the electronics supply chain so that you can locate, source, and place the components you need for your target PCB layout. These features are part of Altium Designer's unified PCB design platform, giving you more control and accessibility with your design.

Find out more information by talking to an expert at Altium, or learn more about how Altium Designer helps you design to cost.