How Increasing Battery Size Guides the PCB Designs of Apple and GoPro

Have you noticed how much more energy it takes to get around as you get older? I used to regularly drive four hours to see some good friends of mine. Now I’m lucky if I have the energy to drive 40 minutes. As a result, I try to lay out my trips to maximize efficiency. Strangely enough, our consumer electronic devices have the same kind of problems. As time goes on, power requirements for connected devices keep increasing. As power needs rise, batteries become more important. Apple’s iPhone 7 and GoPro’s Hero5 give us specific examples of how batteries can limit or enable devices, and how they’re dealing with batteries in their iPhone PCB layouts.

More Power, Bigger Batteries

I’m not the only thing that needs a lot of energy to get around. My gas-guzzling car needs a good amount of fuel too. Despite the continued push to decrease integrated (IC) power consumption, faster chips add to PCB power requirements. New bells and whistles for connected devices use more electricity as well. Bigger screens and new features like GPS and better-quality cameras are adding to the higher power requirements. These factors have all pushed for bigger, better, batteries.

While chips have been getting twice as fast every two years, batteries have been making similar advances around every five years. For some companies, such as Apple, this means squeezing the largest possible battery into their devices. For others, like GoPro, the latest and greatest batteries enable them to add new features.

The new iPhone 7 is a fantastic example of how a well-planned layout can accommodate large iPhone battery sizes. The iPhone 7 uses a custom-shaped logic board and state-of-the-art chips to fit this year’s tech in last year’s form factor.

While the transistor count in the iPhone 7’s processor increased from the iPhone 6, the space available did not. You know what that means, a bigger battery! As you can see from the linked teardown, the iPhone 7’s insides are dominated by its battery. As a result, the logic board, which Apple speaks for the motherboard, is a long, thin rectangle next to the battery. With extremely limited space available, Apple went with the latest, greatest, and smallest ICs. Almost every millimeter of surface space is taken by surface-mounted technologies (SMTs). When surface space is at a premium, internal routing techniques become much more important.

Unfortunately, consumers are never satisfied. Even with such a small PCB and large iPhone battery sizes, many users are unhappy with the iPhone 7’s battery life. Designers working on the iPhone 8 will need to specify even smaller chips and use more efficient layouts to make room for an even larger battery.

GoPro Hero5

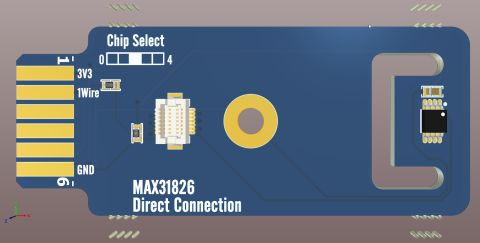

The GoPro is another electronic item whose battery dictates its layout and components. Most GoPro users can’t just stop what they’re doing to change a battery. So, GoPro aims for an approximate 2-hour battery life for its adventure sports cameras. Luckily for GoPro, battery advancements have allowed them to add more features to their camera while keeping them the same size.

With Apple, we saw that the battery was a limitation, but it seems for GoPro new batteries can give them more than enough power. I say this because GoPro has added features to the GoPro Hero5 including more microphones, GPS, and digital video stabilization. All of these have been added while keeping the same size battery. Some users even report that the Hero5 gets better battery life than previous models.

Like the iPhone 7, the motherboard of the GoPro is also forced to have an odd shape. With the Hero5, though, the motherboard has a cutout for the lens, not the battery. In fact, the battery in the GoPro is so unobtrusive, the PCB is less crowded than the iPhone 7’s. We’re comparing apples to oranges here, but you can see that when the battery is not too large, the PCB designer has a little more room to breathe.

Where Apple is limited by battery size, GoPro is enabled by it. The iPhone 7 barely managed to squeeze everything it needed onto its tiny PCB. The Hero5 had so much extra space on the PCB, the designers actually added features. In both devices, batteries are central to design. As Moore’s Law marches on, battery technology will become even more important. Soon, the first question designers will ask is, “what will my battery let me do.”

I might not be able to move as quickly as I used to, but all my devices are certainly speeding up. Increasing battery sizes are going to change your designs one way or the other. Either they’ll make you shrink your PCBs, or they’ll leave you with extra power and you’ll have to add new features. Both ways, you’ll probably need to make some changes. Change is never fun, but having some good PCB design software can reduce the pain. Whether you’re squeezing components onto a tiny board or adding components because you have extra power, CircuitStudio® is the software for you.

Have more questions about batteries? Let an expert at Altium educate you.