Conveying Your PCB Design Intent with PCBA Drawing Creation in Draftsman

Table of Contents

For many businesses, drawing creation is a critical step that may be neglected during product development. Sometimes, these drawings just take too long to create due to the level of detail involved. In other cases, companies might rely on an external contractor or their manufacturer to create their drawings. Alternatively, electronics companies that are creating their own drawings are usually doing so with mechanical drafting applications, which is time-consuming and prone to errors.

Without a way to streamline the manual drafting portion of drawing creation, drawing creation is a time-consuming process that incurs additional costs, and yet standard PCB fabrication and assembly drawings are needed by manufacturers to ensure defect-free PCBA manufacturing. Instead fo using the same outdated mechanical drafting applications from yesteryear, companies should take advantage of smarter, more cost-effective solutions.

Drawings Show PCB Design Intent

Companies that develop innovative products to be released to market at high volume need to ensure they can produce their products anywhere. Capacity constraints at one manufacturer can force companies to contract at multiple manufacturers, but there has to be some way to ensure everyone involved in production has all the information needed to fabricate the same board to the same quality and yield.

This is where your drawings come into play: they show your manufacturing partners everything they need to know to ensure the same product can be produced from multiple manufacturers. If you're working at a service bureau, the same ideas apply to your customers; the drawings you deliver should include all the information the customer needs to produce the product anywhere with practically any manufacturer. This might sound more complex than it seems, but it requires including some specific information needed to move a product through the standard PCB manfuacturing process.

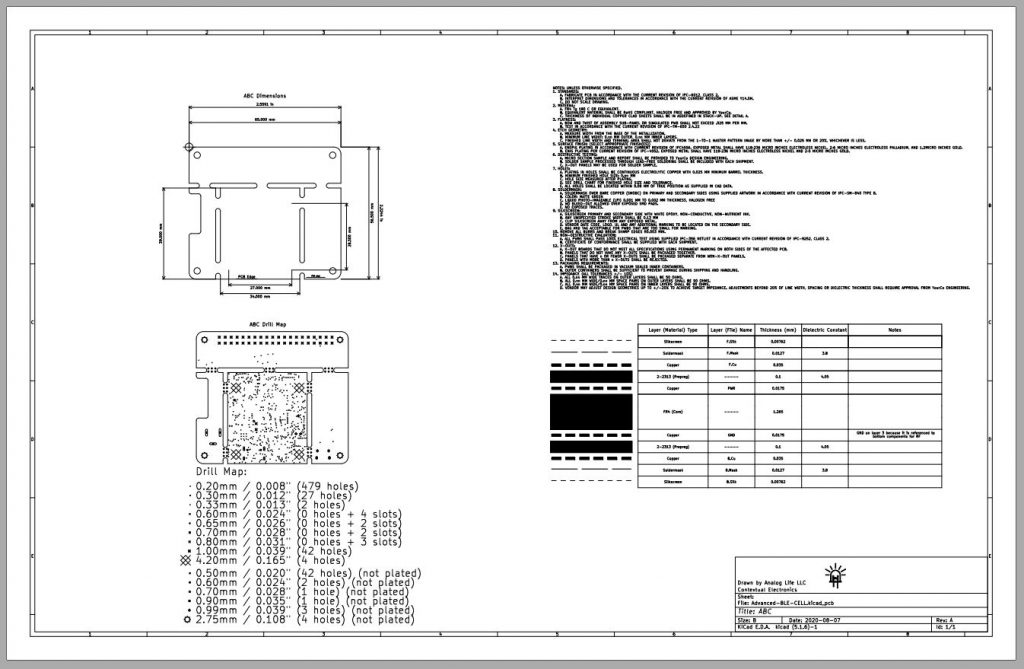

The drawing below shows all the information needed to accurately fabricate the design and produce a bare board that meets basic specs. Here we have some important information included in the drawing:

- A set of fabrication notes listing performance and qualification requirements

- A dimensioned drawing of the board outline with slots and holes clearly visible

- A drill drawing complete with symbols representing different drill hole sizes

- A complete title block with company, author/artist, project, and product information

- A stackup drawing listing layer information

Other information that might be included would be an impedance table, notes with requirements stated in external documents, testing requirements, and more tolerances on fabrication capabilities.

Your PCB fabrication and assembly notes provide an opportunity to list much more detail than you could fit into a quote form. Along with these notes placed directly in a drawing, it's common to prepare a design requirements document that lists everything needed to fully understand the device design requirements, functional requirements, manufacturing and evaluation requirements, and much more.

While requirements document creation is still fully manual, there is one part of the documentation process that can be quickly automated with the best PCB design software: drawing creation. Automated drawing tools can help you quickly create a draft of your PCBA complete with the need-to-know fab and assembly requirements for your design.

A Simple, Practical, Integrated Solution

Where ECAD networks lack in documentation, drawing creation in Draftsman® makes up for by eliminating the need to manually transfer information from an ECAD application to drafting software. Draftsman technology not only makes this process seamless with built-in automation, but also allows the creation of technical drawings for PCBs, which can be utilized for future designs. Overall, this ensures your design intent is conveyed early on in the development process for easy product fabrication and assembly. Draftsman's drawing editor benefits these processes by:

-

Providing a comprehensible, graphical representation of your product design

-

Conveying relevant information regarding the PCB construction

-

Mitigating the loss or potential corruption of design data during development

Because Draftsman technology is fully integrated with Altium Designer®, drawing creations can be accessed directly from the design tool without needing to import or export data from one program to another. Many designers find themselves revisiting older PCB designs for multiple projects, and Draftsman technology makes it easy to reference previous drawings for quick, straightforward replication.

When you need to quickly create PCBA manufacturing documentation for your design, use the Draftsman feature in Altium Designer®. Together with the OutJob file feature, you can quickly and easily generate manufacturing files without using a separate CAM application. When you’re ready to share your design outputs with collaborators or your manufacturer, you can share your completed design data through the Altium 365™ platform. Everything you need to design and produce advanced electronics can be found in one software package.

We have only scratched the surface of what is possible to do with Altium Designer on Altium 365. Start your free trial of Altium Designer + Altium 365 today.