BOM Automation: The Benefits of Having an Automated Bill of Materials in Project Management

Table of Contents

I have some friends who founded a startup company to create and market a brilliant new product. Their product quickly became a success, but all their hard work was constantly undermined by communication issues between departments. It wasn’t long until the engineers found their creative hands tied, purchasing was buried under an avalanche of unreliable documentation, and the product build-in manufacturing was slowed to a crawl from incorrect and missing data. Without product in the pipeline, sales fell off and the company floundered.

So just what problem in interdepartmental communication led to this disaster? It was all due to simple mismanagement of part control in the bill of materials. In this article, we will discuss why software bill of materials is beneficial.

The life cycle of a Bill of Materials (BOM)

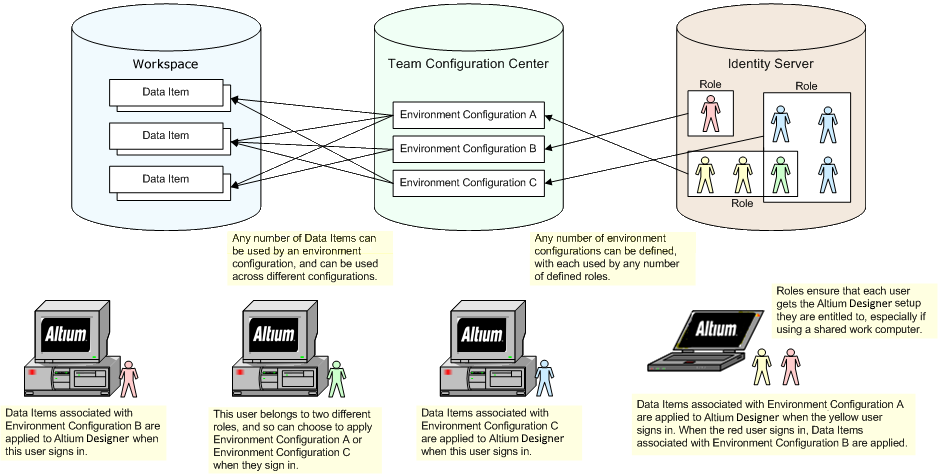

Your company's departments need clear communication to effectively manage a product's parts. When this process is working, the engineering, procurement, and manufacturing of a product move along smoothly. In general, this is how it works:

-

Engineering creates a bill of materials for the different aspects of the design.

-

The purchasing department will take the engineering BOMs and determines which parts are available for purchase based on costs and availability.

-

Manufacturing uses the BOM to build and test the product completing the cycle.

There is a lot of back and forth between the departments during the design phase. The engineers may decide to substitute different parts from what they originally specified based on feedback from purchasing. Meanwhile, manufacturing will be analyzing the design to make sure that the requested parts are suitable for their processes and send their results back to engineering for more changes.

A problem can affect each successive step in the process like a string of dominoes going down

Manual BOM Management

Each step in managing the project Bill of Materials process affects the next step. If there are problems in one area, those problems will impact the next step. If left uncorrected, the whole process can go down like a string of dominoes

Engineers who don’t have current part information won’t be able to make informed decisions on what parts to use. If purchasing doesn’t get accurate information from engineering, they can’t give reliable responses back to engineering or adequately prepare manufacturing for what will be coming. Manufacturing will be the last domino in line to go down as product lines are slowed or shut down due to incorrect or missing BOM information.

management tools can help you to improve production

How Automated BOM management tools can help you

Exercising control over the bill of materials, however, can guard against these problems and help keep the dominoes of your product production upright and in place. Using a central database to manage your bill of materials will also help. Here are some benefits of good BOM management:

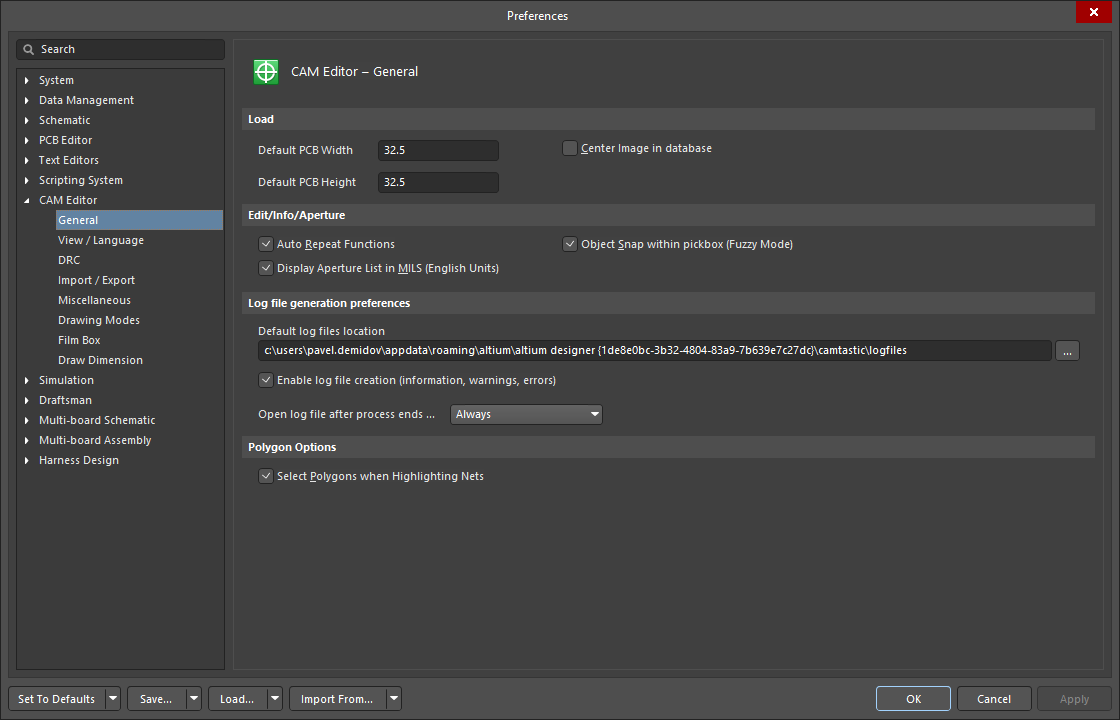

Immediate part inventory access: Engineers can have real-time access to company part inventories to see what is on hand and what they will need to research and order. By eliminating the need to send a spreadsheet to purchasing and waiting for them to create a BOM, the engineer can continue the product design cycle without unnecessary interruption.

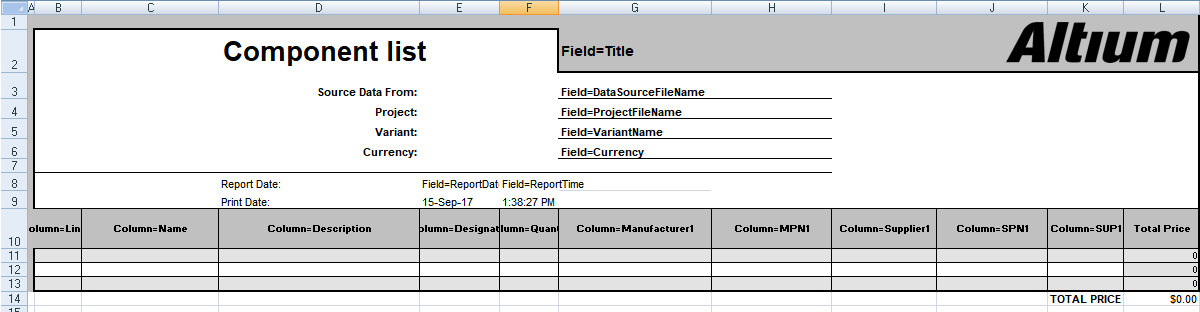

BOM creation as a living document: Creating, changing, and updating the bill of materials can be a continual process as the product is being designed instead of being put together at the end of the design cycle. This gives complete revision control to the engineer while also providing the ability to track changes. It also eliminates the errors that can come from having a second party create a BOM from an engineering spreadsheet.

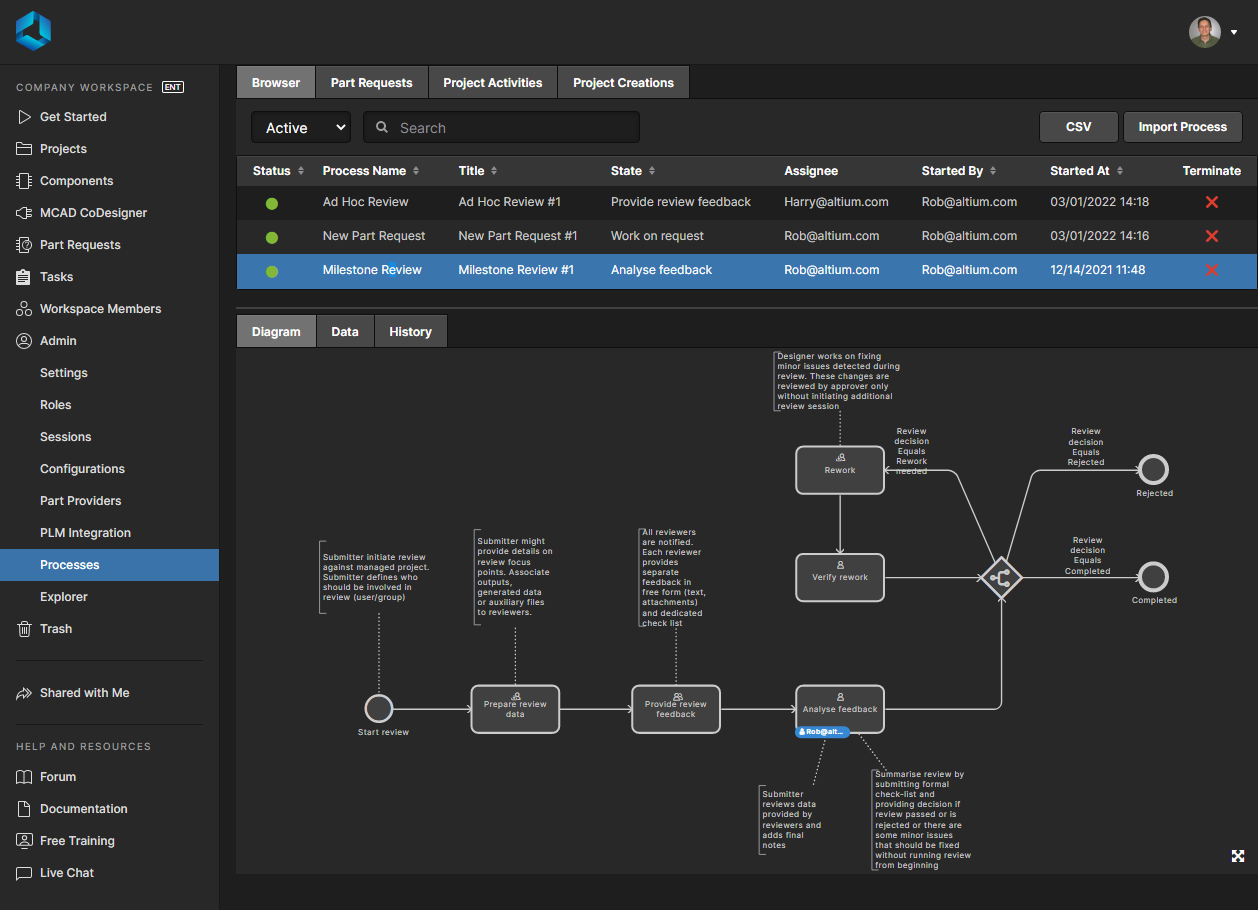

Part requests: Purchasing will receive real-time engineering part requests from the BOM database instead of having to wait for individual spreadsheets to be distributed. Not only does this process reduce the possibility of errors, but it saves time too.

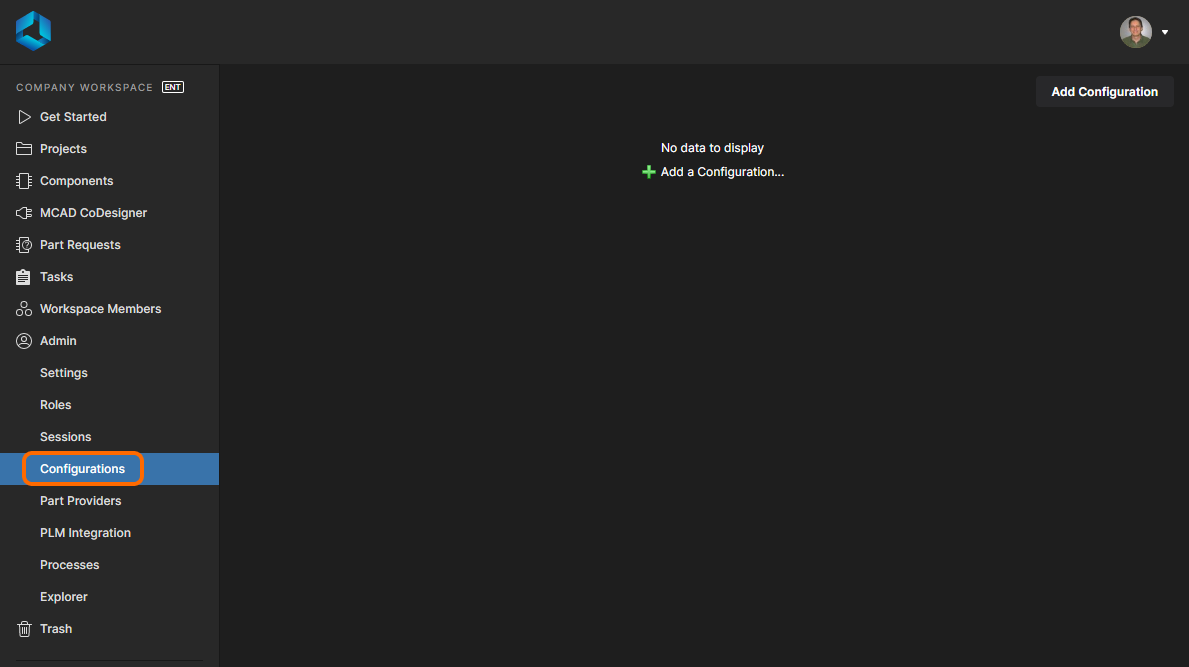

BOM management tools allow for efficient communication between departments: By working together in the BOM database, engineering, purchasing, and manufacturing will have immediate responses to part requests and part changes. This reduces the back-and-forth time in the design cycle that used to be required when manually changing the BOM.

Part inventory control: With BOM management tools, purchasing can begin the part ordering process while the design is still in engineering without having to wait for a manually created BOM from an engineering spreadsheet. This allows part ordering to already be in the queue, and part inventories stocked and ready when the board is manufactured.

No delay in manufacturing: With BOM management tools at their disposal, manufacturing is able to prepare in advance for unique part assembly requirements. Bill of Material management reduces the prep time that manufacturing takes in getting ready to start a run.

The advantage of material management using BOM management tools can reduce errors and shave precious time off your design cycle. This will ultimately save your company time and money making your product delivery a success. For easy-to-use Bill of Materials management software free, check out Altium’s BOM management tool. It is easy to download and will make your life a whole lot easier once you get started with it.

Want more info on a bill of materials management solutions? Talk to an expert at Altium.