To Wave or Not To Wave: Wave Soldering Advantages and Disadvantages

Table of Contents

PCB manufacturers have multiple options for soldering components to a PCB. They have their disposal reflow soldering, selective soldering, hand soldering, and wave soldering. Among these, probably the simplest in terms of complexity and capability is wave soldering. Here is how wave soldering works, as well as how it can be used in mixed technology boards alongside reflow and/or selective soldering.

What Is Wave Soldering?

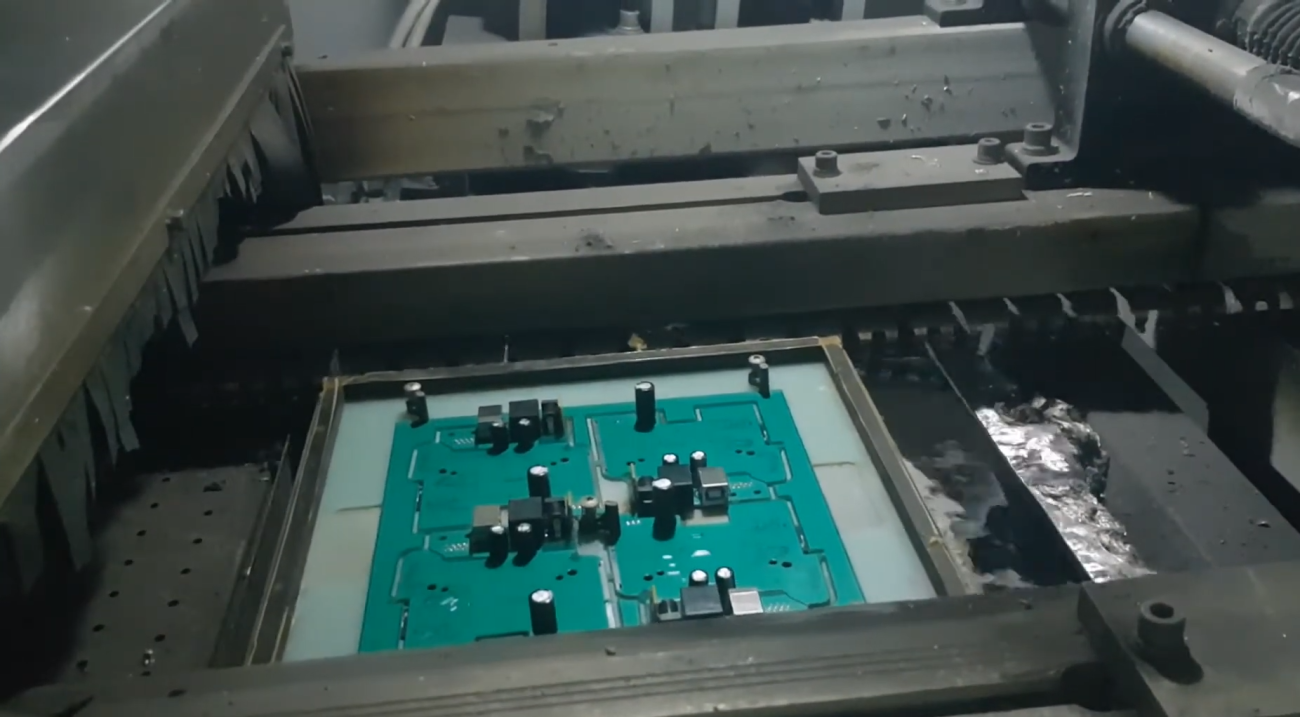

The process for wave soldering is quite simple. A bath molten of solder is passed over a PCB after through-hole parts are mounted onto the board. The solder is passed over the board such that it resembles a "wave," thus giving the process its name. The steps for wave soldering are as follows:

- Through-hole parts are mounted into the PCB

- The board is placed into a tray that exposes mounting holes to solder

- The tray is placed onto a conveyor and is passed into a soldering machine

- A wave of molten solder is passed over the tray and molten solder adheres to mounting holes

- Solder joints form as the molten solder cools

- AOI is performed to identify poor solder joints and determine if manual rework is needed

- The boards are washed to remove any excess debris and for protection

Placement of boards in a tray is most important as it allows multiple boards to pass into the soldering process as a group. The exposed through-holes are soldered via the back side of the board, so it is especially useful in simpler boards with through-holes only on one side of the PCB.

What are the Advantages of Wave Soldering?

Wave soldering has been around a long time and was the primary method of soldering components to a PCB when boards were larger, components were practically all through-hole components, and parts were sparsely placed on the board. Wave soldering provided an automated way to produce large numbers of boards quickly. The advantages are straightforward:

- No solder paste application process is needed to secure components.

- Board areas where no solder is required do not need to be masked off, and no paste mask is required.

- Soldering machines that perform wave soldering are relatively simple to operate.

The designs you see today are a far cry from the designs seen in the past. Most PCBs include densely packed SMD parts that minimize space. These design attributes do not support the use of full board wave soldering. Instead, selective soldering, or rather selective wave soldering, is one option for targeting specific components or regions of the board. I discuss this more below.

What Are The Disadvantages of Wave Soldering?

The main disadvantage of wave soldering is that it is difficult to use with mixed technology boards. There are certain cases where it can be used, which I outline below. Designers do not generally apply DFA principles in terms of soldering process selection; their view is almost always "I'm going to get the layout completed, and I'll let the manufacturing people figure it out." This has led to most boards having predominantly SMD parts, and there will be a few through-holes scattered around the board (many times just connectors).

In some cases with mixed technology boards, the assembler might choose to instead use selective wave soldering. When compared to reflow or selective soldering, full board wave soldering has disadvantages; including:

These factors in part determine whether wave soldering is still viable when a PCB has mixed technology. In some cases, despite the use of mixed technology, full-board wave soldering can still be used.

Does Anyone Still Use Wave Soldering?

The answer to this question is an emphatic "yes" as there are many systems that still only use through-hole components. You can find many examples from power systems, industrial systems, interconnect boards, and the like. It's also possible to use wave soldering with mixed technology in certain instances. Some of these instances include:

- The through-holes can withstand multiple reflow passes; wave soldering could be performed first, followed by reflow

- All the SMD components are on one side of the board, and wave soldering can be used to mount through-holes

- The SMD components are not too small/dense dense and could be mounted with selective soldering after wave soldering

Despite the above points, the use of wave soldering is certainly not as ubiquitous as in the past. Reflow soldering has largely become the primary method used to assembly PCBs, followed by selective soldering and wave soldering. For some parts, or if you look overseas, you will also see hand soldering still being used. One process that can be used with mixed technology boards is intrusive soldering, also known as pin-in-paste soldering. If your PCB design includes mixed technology, your assembler can determine the best mix of processes to assemble a PCB such that the number of soldering passes is minimized.

If you need to design PCB footprints and a PCB layout for intrusive soldering, you can get the job done with the best PCB design tools in Altium Designer®. To implement collaboration in today’s cross-disciplinary environment, innovative companies are using the Altium 365™ platform to easily share design data and put projects into manufacturing.

We have only scratched the surface of what’s possible with Altium Designer on Altium 365. Start your free trial of Altium Designer + Altium 365 today.