Surfing 3D PCB CAD from Inside the Grey Tsunami

APEX San Diego – Riding my long skateboard through the streets of the Gaslamp I must have been quite a sight in my suit and tie. Fresh off the IPC APEX show floor, I was carving turns through traffic, heading back to my hotel after spending several hours discussing the positive wave of 3D PCB CAD with some industry colleagues.

Suddenly, I heard two guys laugh and shout at me from the crowded street corner: “Hey, you’re too old to be ridin’ a skateboard!” To the amusement of the two men and an entire crowd of street-goers waiting at the light, I flashed the shaka sign with my hand. Quickly, as the light changed, I gave a holla back at them using a term I’d heard at a PCB designer presentation the night before, yelling “Behold the Grey Tsunami!” Appreciating the sound of more laughs from the street, I skated on.

The Grey Tsunami metaphor had been used to describe the aging population of PCB designers who will soon be catching their last wave out of the electronics industry and presumably taking their collective PCB design knowledge and experience with them.

Wait… Everybody out of the water! What?!?

I’ll say it again. The people behind the success of most everything that works in the PCB industry—the baby boom generation of PCB designers—are on their last wave. They are retiring.

For decades, PCB designers have been laying out PCB designs with software that has continually had to evolve, driven to meet the needs of the experienced designer.

The evolution came by way of designer work-arounds. From customized land geometries and tear-dropped pad routing to positive flooding of copper planes. From Dynamic Routing of differential pairs to automated length matching of critical routes. From manually imported DXF templates to highly detailed mechanical step files. The experienced PCB designer had always known what was graphically needed to complete a design before the software ever evolved to become a tool which could easily provide it.

For instance, some of our millennial generation PCB designers might find it trivial to learn that there was only one flavor of automated power plane creation before the fall of the “dot-com” era around 2000. Negative internal planes were all that the design tools could create at the time. But as the design technique of flooding outer layers of a PCB became more accepted, designers were improvising by using their own geometric tricks to fill the planes around outer layer land geometry. It wasn’t until a PCB design benchmark event held at PCB west in 2000, that the industry witnessed the first PCB design software that could perform automated outer layer copper flooding.

The moment stands as an excellent example of an EDA company answering the call of experienced PCB designers by adding features to their tools that proved to help them design, thereby forcing all competitors to follow. But with new capability came a need to educate designers on outer layer print, etch and plating constraints. Even today, almost two decades later, designers are erroneously using the same clearance rules and inner layer copper planes (print and etch) for outer layer flooding which requires more clearance for the additional plating step.

With decades of PCB design experience washing out in the wake of the grey tsunami, we are already seeing signs of a sea change in PCB manufacturing. The electronics industry is being flooded with new electronics engineers who are taking on the challenges of PCB design and layout.

As the new wave of electronic engineering prospects takes shape it is generating excitement from the shore of industry onlookers. But as new PCB design “gremmies” paddle their design tools out to catch their first waves, the PCB manufacturing portion of the industry is preparing for an endless summer of gnarly design wipeouts—impossible PCB stack-ups, dreadful print and etch challenges, unmanageable drill aspect ratios—all of which are combined with awkward or missing data, design specifications and documentation.

Due to great improvements in PCB layout tools driven by the experience of the baby boom PCB designer generation, our emerging millennial PCB designers can learn to operate EDA tools scary quick! But learning to design—that is to gain enough experience to meet the electrical performance criteria while meeting many other constraints such as cost and manufacturing as well—is not yet achieved by the press of a button. PCB design must be learned through communication with PCB process stakeholders and understanding their capabilities.

An EDA company which rejects the reality that “ease of use” functionality does not stand on its own and must be coupled with tangible PCB design education will find that its product is enabling new designers to easily create designs which will fail!

With the increasing void of experienced designers available to mentor the new EEs, the EEs are looking to the PCB layout tools to guide them to success. It is no secret that PCB CAD companies are well aware of this. There are ongoing corporate efforts to address this dilemma. What is the right approach?

Capture the Foundational Design Experience of the Past

PCB design educators and education programs have laid many foundations for PCB design with regard to how signal integrity and overall electrical performance is affected by the interwoven combinations of components, conductors, dielectrics and environment. Progressive EDA companies will do well to actively participate, support and capture all of these foundational concepts as they are presented in blogs, booklets, seminars and design expo meetings in order to address these concepts in their design software as foundational functionality. Merely trying to embed this foundational information as “default settings” in the software tool has been proven to lead the new designer toward failure. There have been actual cases of un-manufacturable data showing up at the PCB supplier because the new designer sadly assumed the default settings were set to be manufacturable!

Connect Designers with Present-day Industry Stakeholders

While the physics of electronic components including printed circuit boards have not changed over the years, the packaging density and signal integrity parameters have changed drastically. Every day, designers are faced with new components which are smaller than ever. Some new chip resistors are small enough to fit inside the zero of a 2019 date marked penny!

But just because new parts are available for good electrical performance does not mean they are always the best choice for purchasing stakeholder availability. It does not mean the parts are the best choice for assembly stakeholder machine processing. More than ever, PCB designers need to be introduced to all of the stakeholders in the PCB industry in order to design for the success of all. Connections are being made to high-speed engineering, fabrication, assembly, and test stakeholders through EDA tool software capability.

We are seeing integrated software that now can define specific materials, calculate trace impedance and which auto-generate dimensions and tolerances for manufacturing panels and assembly arrays. But without connecting the new users of these design and documentation capabilities to the stakeholders they affect, EDA tool suppliers are again enabling the new designer to fail.

What good is it for a PCB design tool to supply a capability of geometric dimensioning and tolerancing using IPC-2615 to a new user who has never taken a dimensioning and tolerancing class? Oh dear, please help the manufacturing stakeholders who receive design documentation from a new designer who thought it would be a good idea to apply this functionality without proper training!

Build a Dynamic PCB Stakeholder Community

So let’s not misunderstand. Watching an EDA tool webinar showing layout software which can address the next wave of features added to help all of the PCB industry stakeholders is an awesome spectacle to behold. So is watching experienced surfers ride the massive sixty-foot waves at Maverick’s, a surfing location just North of Half Moon Bay in California. A wise EDA company will recognize that only experienced professionals surf these waves. Ones who have sought wise counsel from those who have gone before and have assembled support teams of rescue helicopters and personal watercraft to complete the ride out of danger once the wave is ridden. No one in their right mind would encourage a novice to try these things. Especially alone.

Mindful EDA companies recognize that it is vitally important to build a community of PCB stakeholders to support their newest waves of tool capability. A healthy PCB design community must include input and review feedback from all of the personnel who will benefit from its use or become hurt by users who wipe out. Signal integrity performance engineering, component engineering, supplier management, manufacturing engineering, test engineering, and even customers need to be brought together to share and learn. Like the PCB designs themselves, events must adhere to certain constraints. They must be affordable, interesting, fun and engaging. They must serve to build a PCB community.

What Will Be Left of the PCB Industry in the Wake of the Grey Tsunami?

Regardless of the era in which you learned or are still learning PCB design, the profession has always had a great benefit. PCB design is in a class of technical jobs in which listening to your favorite music while routing can actually increase your design performance! A PCB designer can go on through the night to finish a job by morning if the right music is playing in the headset. I’ve often allowed hours to go by unnoticed while routing to the surf rock tunes of Dick Dale and the Del Tones. Sadly, the world recently lost the “King of Surf Guitar.”

But since Dick rode his last wave out at the age of 81, his industry—the music industry—has done a great job of making sure to record and document his work from its foundation. There are countless recordings, YouTube videos and even surf rock festivals which will ensure his legacy lives on. And best of all, PCB designers can continue to listen to his classic song “Miserlou” while routing countless DDRx design tracks for hours on end.

The music industry has made it possible for anyone with access to media or time to attend live events, the ability to acquire instruments, learn to play, and even make a living playing them. PCB designers young and old can only hope that our industry—the electronics, PCB design industry—led perhaps by the EDA tools suppliers themselves, is doing a good job of preserving a similar PCB designer legacy for our future PCB designers. Next-generation PCB designers not only need access to capable tools and proper instruction for using them, they need to be introduced to “everyone else” involved in the PCB manufacturing workflow in order to understand how to contribute to a healthy livelihood for themselves while contributing to a content and efficient PCB stakeholder community.

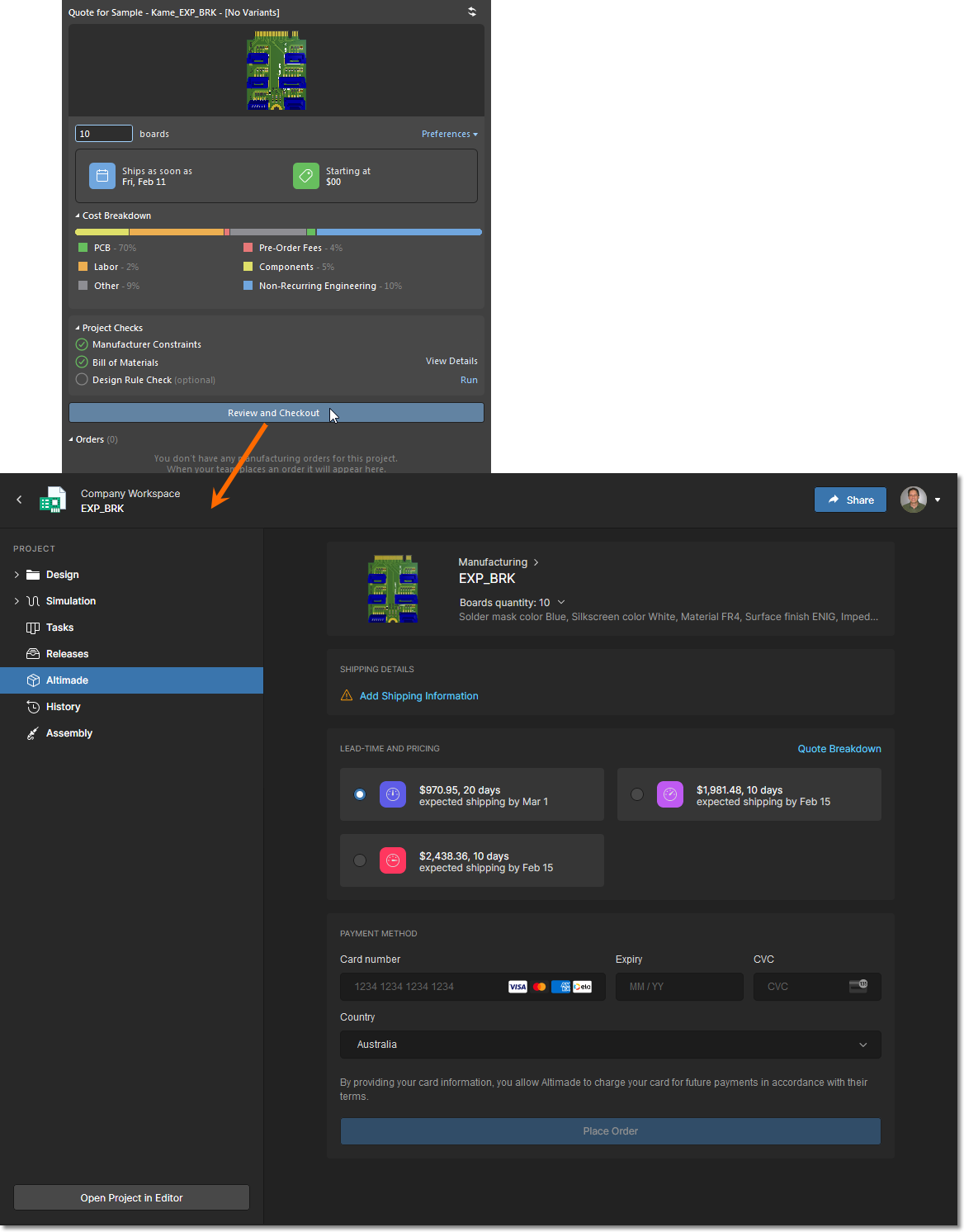

Would you like to find out more about how Altium can help you with your next PCB design? Talk to an expert at Altium or read more about choosing the right manufacturer and generating deliverables in Altium Designer®.

Add a new seat of Altium Designer® today and

SAVE 40% on the purchase price.