Warning Signs You Need PCB Data Management

Table of Contents

I get a gut-wrenching feeling when people are doing PCB Design and ignoring all the warning signs around them. It’s like in the movies. I enjoy watching horror movies, but too many times I find them more funny and predictable than scary. Why is it every time the “bad guy” starts to chase the unfortunate helpless victim, their automatic response is to run to the top floor of the building? Everyone is shocked when the person meets their “unseen” demise. Nothing was surprising there. The other thing is can always tell when something is about to happen when the music suddenly turns eerie. It never fails, I am the one who sits there yelling at the screen, “Hey maybe it’s not the best idea to go up there?”

When things start to go wrong, people are shocked; wondering how it happened just like in the movies. Many things can occur as a result of poor PCB Data Management. So, it should be no surprise. I’ll list them here, but of course, in no way is this a complete list. You will find the more you work in PCB Design, the more you will begin to see those little warning signs. That way you would be the one yelling “Hey maybe not the best idea to go there?”

Consequence #1- Company Lost time and Income

The most significant consequence of working with poor PCB Data is lost company time and income. With a dog eat dog environment, companies try to reach a rather high bar. That forces everyone to work smarter and more efficiently. When will the product be released to customers, is the first question? So, reducing the time from concept to market is vital. With all that said, what that means for us PCB Designers is we do not have the time or the money for multiple spins of board designs. They need to be right the very first time.

Let me interject something right here. When things go well with PCB design, they go very well...When things go wrong, they go VERY WRONG.

What happens is that unreviewed components placed in a design may get through the fabrication house pretty easy However, when it gets over to Assembly and they place those components on those wrong footprints– congratulations you have reached the top floor of the building, and the bad guy has tracked you down.

Predictably, you start getting the phone calls telling you how they are having “issues.” You end up needing to make that long walk into the manager's office to explain why you just wasted the money and time on a project that yielded absolutely nothing. Not a good feeling at all.

Consequence #2- Lost streamlining of the project

Very close to the first consequence is the lost streamlining of the project. What is meant by that is, the PCB is a process. According to the business dictionary, a process is: “A sequence of interdependent and linked procedures which, at every stage, consume one or more resources (employee time, energy, machines, money) to convert inputs (data, material, parts) into outputs. These outputs then serve as inputs for the next stage until you reach a known goal or result.”

You have a starting point, and you input the initial information. The output of that stage becomes the input of the next and so on. That is a perfect description of a PCB Design. When there is a breakdown in the PCB Data used in this process, you lose the process. There things ran smoothly, inputs go into the outputs. Now, it’s like someone threw a colossal monkey wrench into your system and you lose complete control of your process. Where there is no control, you have chaos.

Consequence #3- Lost credibility as a Designer

More on a personal note, another consequence of working with poor PCB Data is the lost personal credibility as a PCB designer. When lost, one’s reputation is hard to get back. We are judged many times by the last design that we did; good or bad. For some reason, people always seem to remember the bad more than the good. That only heightens the importance of having a system that you can trust. That's also a bit calming. I used to be nervous when I released the Gerbers and started a fabrication. The reasons were, I would start running in my head all the different scenarios thinking about what I had missed. Was it just a matter of time until they came out?

Conclusion

I hate looking only at negative things without looking at something positive. The one good consequence I would share is that when you have a PCB data Management that follows the SMART RULE with the 5 pillars, and you have a controlled process, you end up with confidence regarding your design. Confident that you are using the best information and data, in the best way possible, which will result in the highest board quality possible. This is a much better way to work. The other plus is that you keep your sanity.

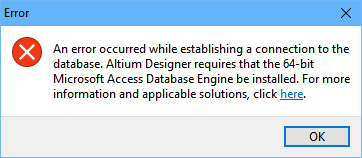

Would you like to find out more about how Altium Designer can help you with your PCB data management? Learn more about solutions for library management and find the easiest way to resolve issues across many PCB designs. Have more questions? Call an expert at Altium.