The Positive Impact of Supply Chain Visibility on Design to Cost

Imagine a world where every design decision you make is cost-effective from the start. This is the promise of integrating supply chain visibility into the design-to-cost approach in engineering. By increasing procurement transparency, you can develop better products faster and align perfectly with budget constraints early on. Here’s why.

Understanding Design to Cost in Engineering

What Is Design-to-Cost Approach?

Design to Cost (DtC) is a management strategy that revolves around designing and engineering products to meet specific cost objectives. This approach ensures that the final product meets technical and performance requirements but also aligns with predetermined cost constraints.

Design to Cost integrates cost management into every aspect of the design and development process. The primary objective is to achieve the lowest possible cost while maintaining the quality and functionality of the product. This strategy involves setting cost targets early in the design phase and continuously aligning design decisions with these objectives. It encompasses material selection, manufacturing processes, design complexity, and the choice of suppliers and components.

The principle is straightforward: design with cost in mind from the outset, not as an afterthought. Why?

Importance of Cost Considerations During the Design Phase

Because the decisions made early in the design process commit a significant portion of the future cost of a product. In fact, 80% of the manufacturing cost and performance of a product is committed in the first 20% of the design cycle.

Early cost considerations help identify more economical alternatives and avoid costly redesigns at later stages. On average, subsequent re-spins can lead to expenses of around $44,000 each.

Understanding these factors is essential for strategic sourcing and maintaining the project's financial viability to create value-driven, market-competitive products. Easy as it sounds, it’s not free from challenges.

Challenges in Adhering to Budget Constraints

Engineers often encounter dilemmas where opting for lower-cost components might lead to compromises in product quality or durability. This balancing between cost-effectiveness and performance is a recurring grapple in the design phase.

There's also the challenge of rapidly changing market prices for components, which can quickly render a well-planned budget obsolete. Sometimes a critical component can be marked up 20 to 50 times higher than the standard list price at the time of production.

Another significant hurdle is the evolving technological landscape. With rapid advancements in technology, designers must constantly balance between leveraging cutting-edge tech and keeping costs under control.

The pressure to shorten time-to-market adds another layer of complexity. Electronic design teams face the daunting challenge of meeting ever-shorter time-to-market requirements and cost objectives in rapidly fluctuating global markets. This urgency often demands swift decision-making, which can be at odds with thorough cost evaluations and risk assessments.

And even if the costs are taken into account, their collecting is not automated. Someone on the team typically must enter data into an Excel spreadsheet for each component. Relying on manual processes is prone to errors and inefficiencies. This approach often overlooks critical factors like lead times, volume pricing, and logistics, which are essential for accurate cost assessment.

A Forrester Study revealed similar conclusions. The organizations in the research group lacked the necessary transparency into their procurement systems and processes to create accurate BOM estimates at the beginning of design cycles. As these projects progressed, fluctuations in component availability and pricing, driven by market dynamics and demand, became apparent.

Consequently, when the teams reached the PCB assembly stage, the need to seek out alternative components became a time-consuming task. If a critical component was no longer available and the alternatives were incompatible with the original design, design rework would require the organization to throw away the initial prototype, which would cost the organization the originally scoped material costs and time.

The solution? Comprehensive supply chain visibility (SCV) allowing teams to access real-time supply chain data and assess design choices with cost objectives in mind.

The Role of Supply Chain Visibility

Supply chain visibility is the ability to track products, components, and materials as they move from suppliers to the end customer. This visibility encompasses:

- Data Transparency: Full visibility into the availability and movement of raw materials and components.

- Supplier Integration: Effortless integration of supplier information into the product development lifecycle.

- Production Monitoring: Real-time tracking of manufacturing processes and capabilities.

- Logistics Oversight: Detailed insights into distribution, including shipping times and inventory levels.

- Market Intelligence: Awareness of customer trends and demands impacting product design and supply needs.

Real-time data availability has a profound impact on decision-making. It allows engineering and procurement teams to:

- Anticipate supply issues, identifying potential shortages or delays in advance.

- Optimize inventory management, balancing stock levels to avoid overproduction or stockouts.

- Enhance design efficiency, quickly adapting designs based on available components and materials.

- Accelerate time to market, without sacrificing quality and performance.

- Reduce costs, avoiding the financial implications of last-minute changes or delays.

And this last point takes us back to validating our initial thesis, namely how better supply chain visibility supports design-to-cost strategies.

How Supply Chain Visibility Impacts Electronics Design Cost

First, transparency in the supply chain makes the team continuously aware of the cost implications associated with their component decisions. Having real-time access to component availability and pricing enables engineers to choose cost-effective components adhering to budget constraints from the onset of the design process. Selecting readily available parts reduces the risk of project delays and the accompanying financial repercussions.

Access to detailed component data, including quality metrics and compliance status, further ensures that designs meet industry standards and regulations, avoiding costly redesigns or compliance-related lags.

Second, supply chain transparency benefits proactive risk management, identifying potential issues such as part obsolescence, long lead times, or sudden price hikes. Early identification of these risks allows engineers and procurement teams to make strategic decisions, like selecting alternative parts or adjusting design specifications, to avoid costly production blockers.

Last but not least, with SCV, engineers and procurement teams can synchronize their efforts to order the exact quantities needed, minimizing excess inventory and associated holding costs.

But how to implement this level of collaboration and data precision across the electronics supply chain?

Modern Tools for Supply Chain Integration

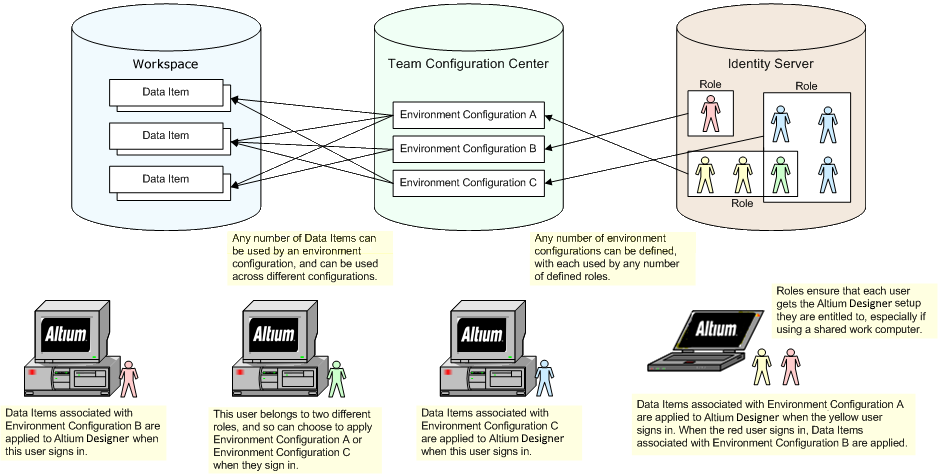

Advanced solutions such as cloud-based platforms, IoT, and AI integrations play a crucial role here. They improve procurement transparency and fundamentally change the relationship between supply chain management and engineering design processes.

In the past, these were largely siloed operations. Now, they are increasingly interdependent, with supply chain information directly influencing design decisions.

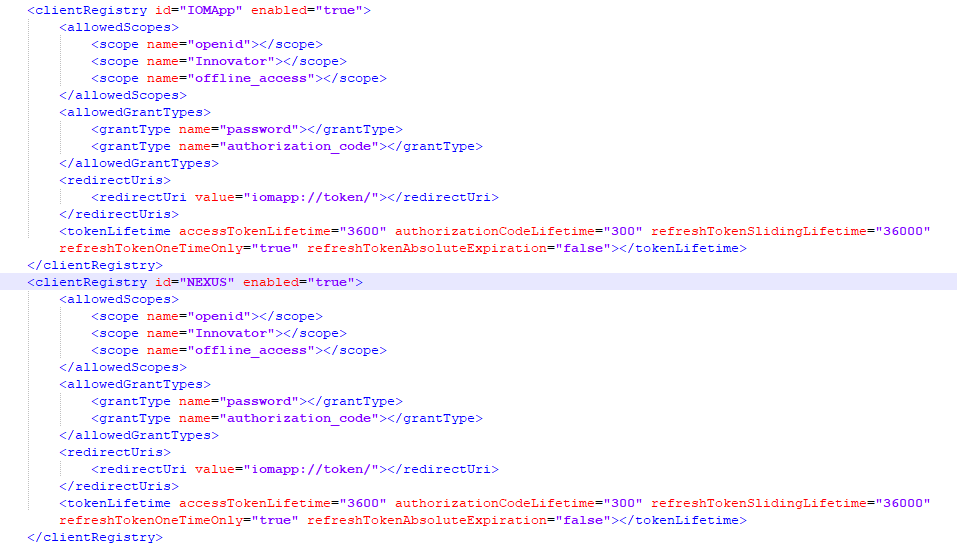

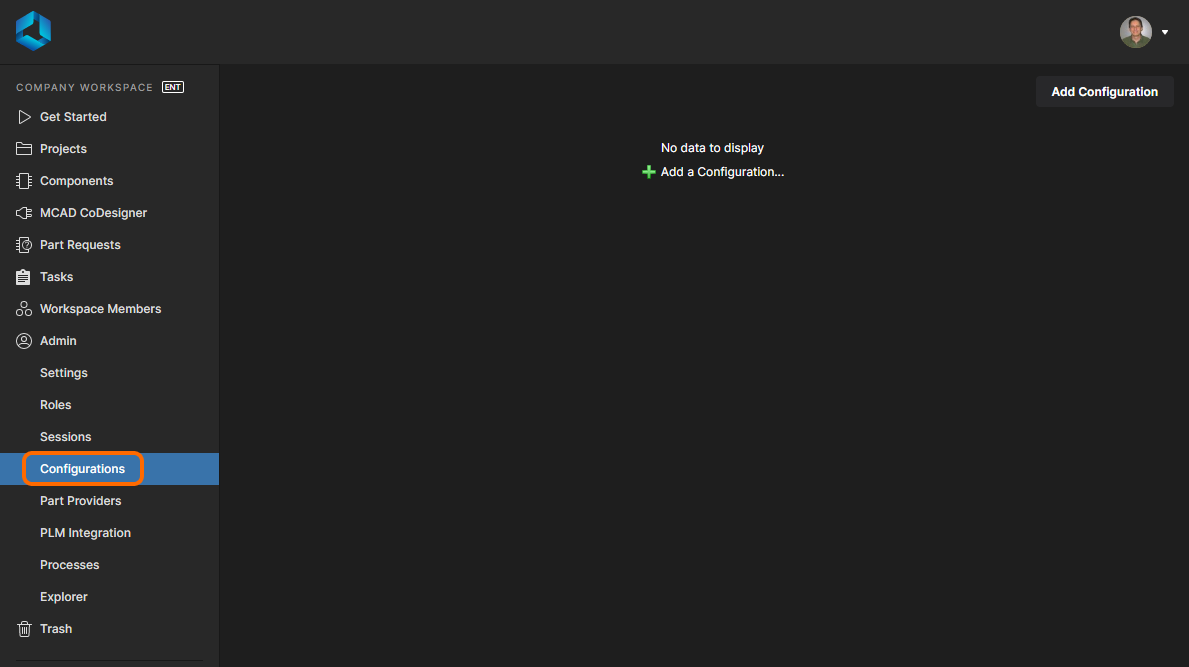

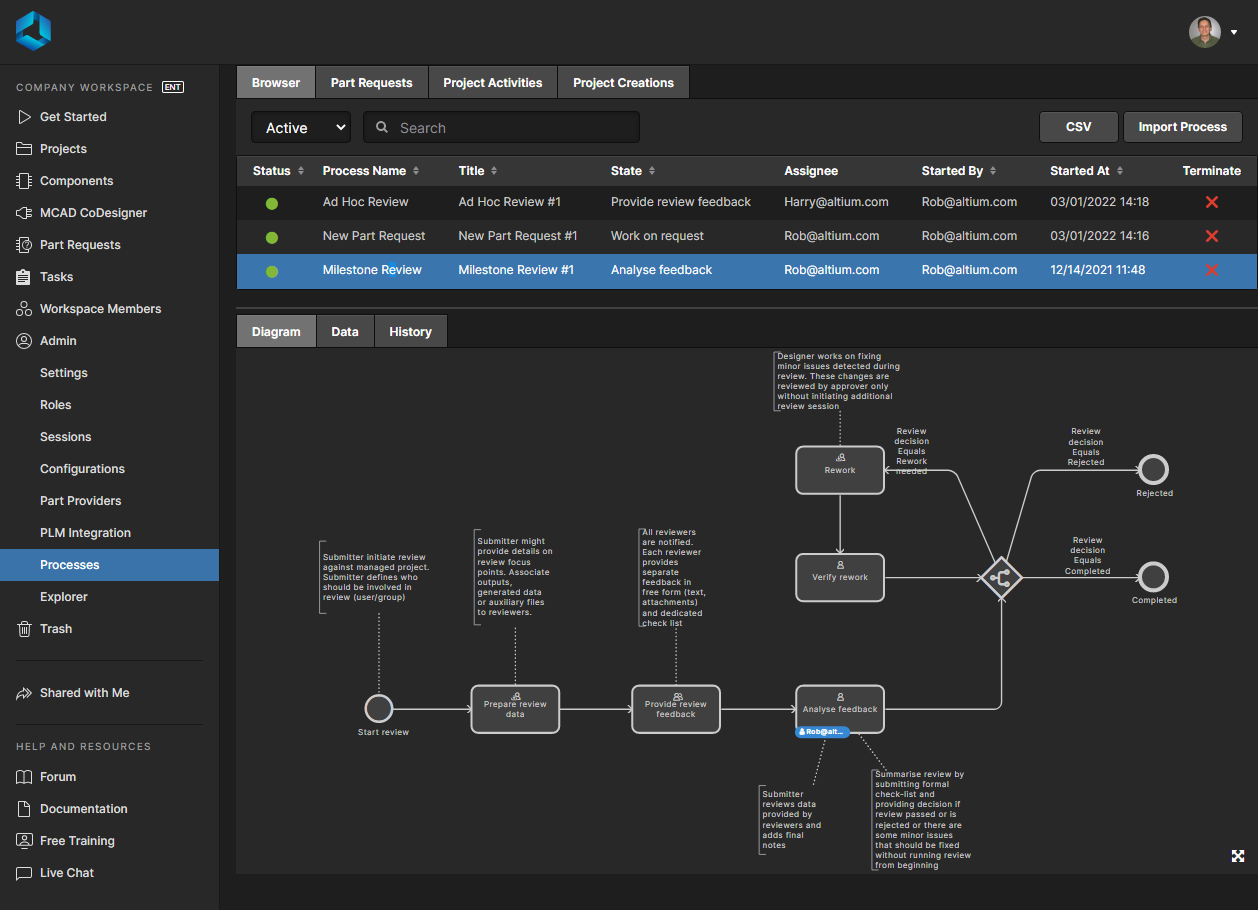

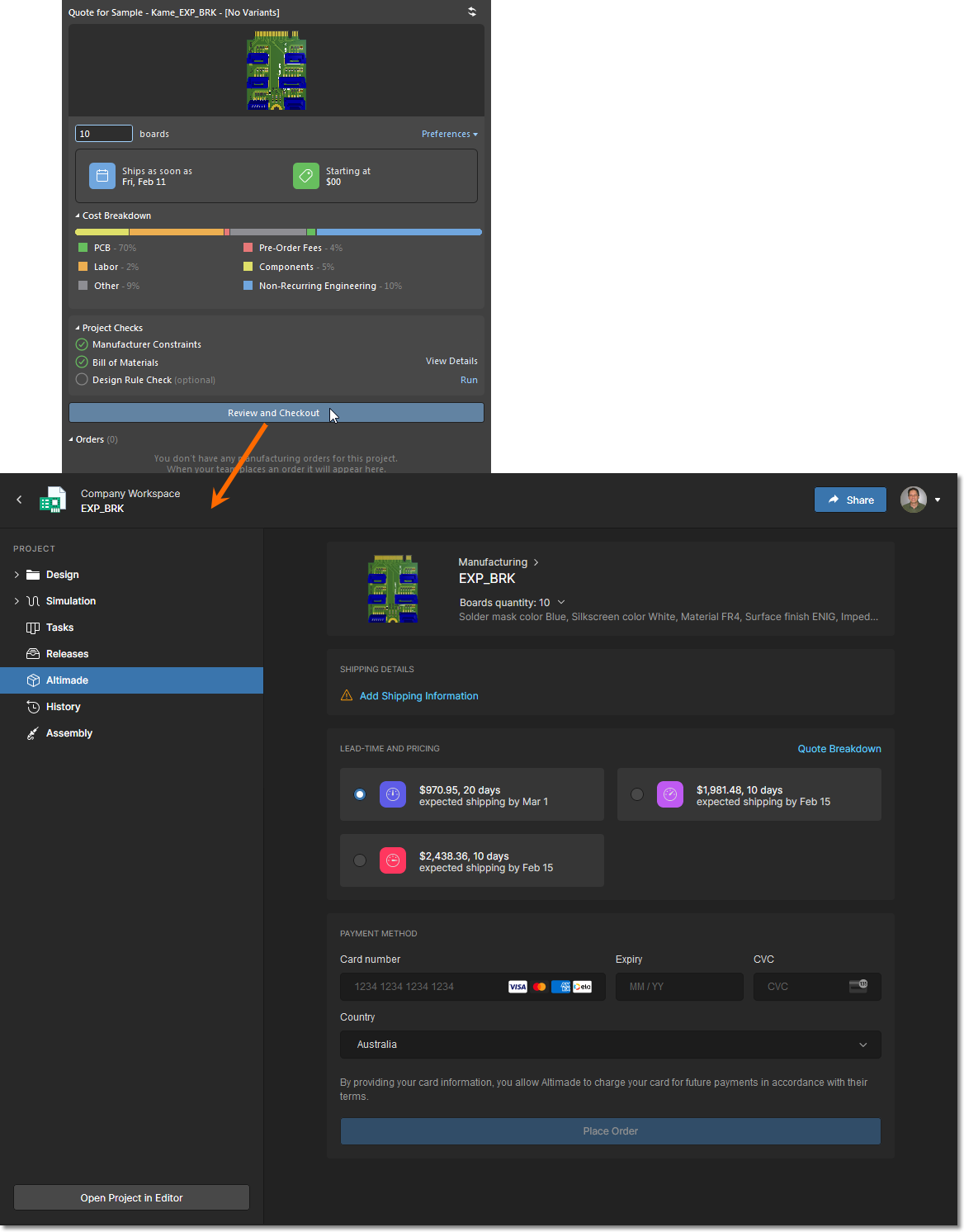

Altium 365 BOM Portal is just one example of this symbiosis. It integrates real-time supply chain data into the electronic design process. Available integrations with the best industry data providers like Octopart, IHS Markit, SiliconExpert, and Z2Data (coming soon) provide additional layers of insight.

BOM Portal allows for efficient BOM management, offering automatic data enrichment, improved risk mitigation, and comprehensive part library and traceability. The ability to flag components for availability issues or pricing fluctuations helps you develop more precise estimates, reducing the amount of throwaway work and the associated costs of PCB prototype runs.

But let’s look at the real-case numbers. How much can you save from enhanced supply chain visibility?

What Is the Value of Supply Chain Visibility?

For the organizations analyzed in the Forrester Study, implementing Altium 365 led to cost savings amounting to $199,301 (three-year present value). Attributed solely to increased procurement transparency!

Further emphasizing this value, a hardware manager from a manufacturing firm in the defense and security sector provided a practical example of this financial advantage. Their organization managed to speed up production cycles by three months. This acceleration was attributed to the reduced issues with design components.

Learn More

So, are you ready to design for cost with increased supply chain visibility? If so, watch the webinar about Altium 365 BOM Portal and learn more about bridging the gap between procurement and engineering. Discover how to leverage the full potential of integrated supply chain management!