Isolated vs Non-Isolated Power Supplies: The Right Choice Without Fail

There may come a time in your career as a PCB designer when your designs will fall under the purview of some kind of regulatory requirements. Whether it be medical, automotive, military, or anything of the sort, your design could end up being scrutinized and held to very high standards. Oftentimes, when these regulations are in effect, power isolation (or lack thereof) suddenly becomes a very popular topic.

What is power isolation, and what is an isolated power supply? Power isolation is essentially what it sounds like: the power supply is isolated from the rest of the circuits in your system. This is a common measure in power systems, and for good reason. For example, with a non-isolated power supply powering your medical PCB, there is a greater risk for dangerous shocks or surges surge through the supply and into your device, potentially harming the user (and maybe even the patient!).

An understanding of isolated vs. non-isolated power supplies is all about designer and user safety. Here, we're not talking about only the AC or DC power supply units you find the lab. For many digital and embedded systems, the power supply is integrated into the board, and it doesn't appear as a single integrated circuit. Power supply isolation, even when integrated into the board or into a multi-board system, will help protect the end user and other equipment. So let’s all do ourselves a favor, and consider the difference between an isolated vs. non-isolated power supply before starting your design.

What is an Isolated Power Supply?

An isolated power supply is a power supply that is electrically isolated from the rest of the circuit that it is powering, often by an isolation transformer. This means that power and voltage is transferred from the input to the output without a direct electrical connection between the two sections. These power supplies can accept a large input voltage from AC mains and convert the input down to a lower voltage. Subsequent PFC and regulator stages might be used to limit the output current to a stable value, which ensures the downstream components are protected from large voltage and current surges at the power supply input.

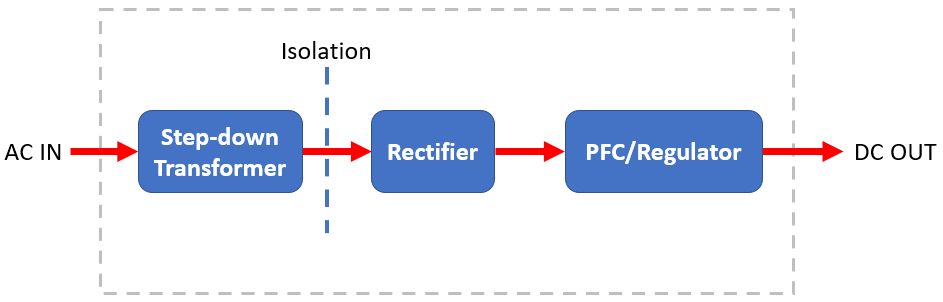

For a lab-grade DC or AC power supply, the user will need to interact with the output stage of the isolated power supply. In other words, they may need to plug or unplug wires, adjust some settings on the front panel, or otherwise handle the power supply unit. By isolating the input from the output, the end user of the power supply is at lower risk of shock when they work with the power supply. A typical topology for converting AC to DC with an isolated power supply is shown below.

Simple topology for the output stage of an isolated power supply via an isolation transformer.

In the above topology, a step-down transformer is shown at the input (between any input EMI filtering and the rectifier circuit) as part of AC-DC conversion, but often times this will be placed after the rectifier and PFC stages, particularly in an isolated DC-DC switching converter. Typically, in high current switching DC-DC converters that require isolation, the strategy in isolated DC-DC power supply design requires driving a half-bridge or full-bridge array of MOSFETs with a pulse stream supplied by a gate driver circuit. This is basically what is done in a resonant LLC converter. The pulsating output from this circuit is then stepped down to a lower voltage with a transformer and smoothed with a capacitor bank. This is also done in a flyback converter, which is a common type of isolated DC-DC switching converter, although the topology may be different.

The above topology doesn't explicitly show you something important: how isolation is actually implemented and the overall grounding strategy. In an isolated power supply, there may be up to 3 ground regions:

- Primary ground (PGND): This is the ground region on the primary side of the transformer, i.e., the input side of the power supply. If connected to single phase or three phase AC, an earth connection may also be present (see below) at the input side as a connection in an input EMI filter circuit. This ground region should run up to the primary side of the transformer, and the edge of this ground region define where isolation arises in the system.

- Secondary ground (SGND): This ground region starts at the secondary side of the transformer and provides the ground reference for the rest of your system. This region might be left floating in your system, although in high power systems this can create significant noise if the secondary ground oscillates around the power ground reference level as the secondary side acts like a floating conductor. This is suppressed at AC with a Y-type cap across the two GND regions.

- Chassis (earth) ground (PE or GND): If this is present in your isolated power system, it will generally be a safety ground. It should not be connected to the output side of your isolated power supply or connected to the power return on any downstream equipment or boards in your system. Chassis is not meant to be a current carrying conductor except in the instance where a fault occurs.

Note that the designations "PGND" and "SGND" are not required; you can technically name your nets anything you want. How these regions are actually connected to eliminate noise and ensure safety while maintaining DC isolation depends on the application. Here are some resources to help you get started in these systems:

- How to Connect Grounds in an Isolated Power Supply PCB Layout

- PCB Grounding Techniques for Plated PCB Mounting Holes

Design Examples

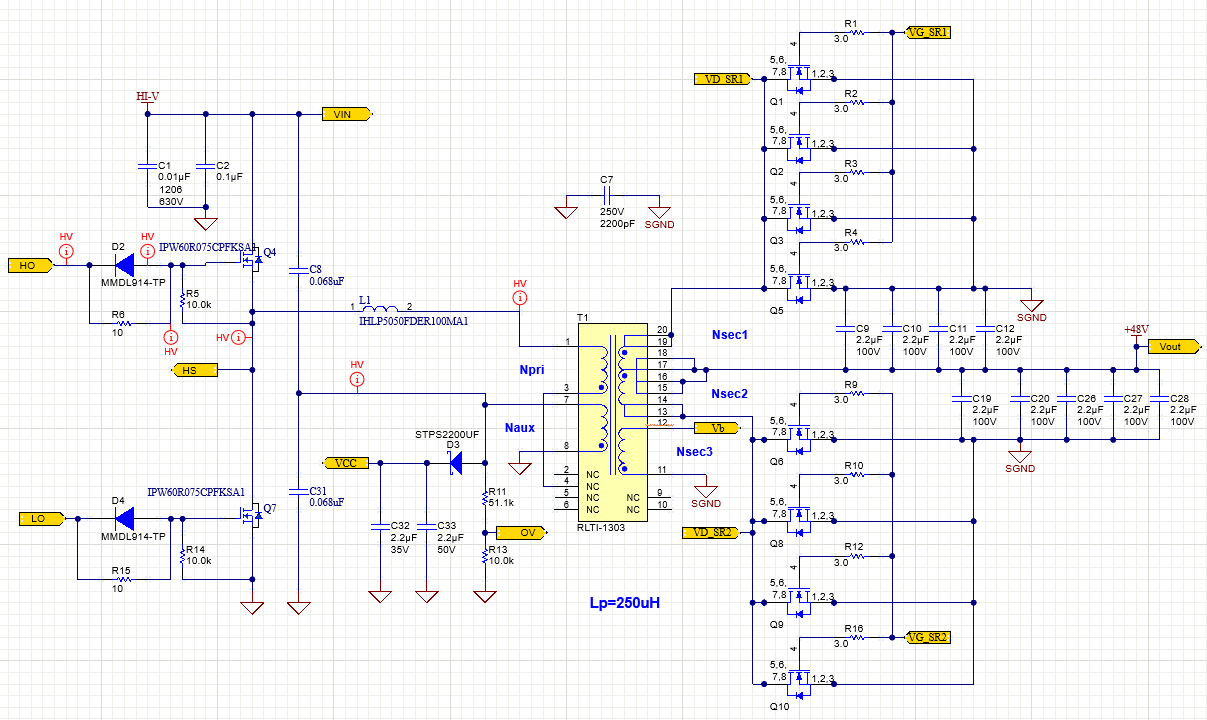

The images below show a design example involving an isolated power supply. In this supply, we actually have two levels of isolation applied between the input and output:

- Initially at the AC input

- Between the push-pull switching stage and the output.

The AC input stage is not shown below as there are multiple reference designs that can handle the initial AC/DC conversion task. The output from the AC rectification stage is fed into a PFC circuit that compensates for reduction in the converter's power conversion efficiency through switching action. The isolated switching stage is shown below.

This is an LLC resonant switching converter, and it is a variant of a design I've shown elsewhere. There is an additional gate driver circuit that switches the stages on the primary and secondary sides of this resonant converter. We know that this converter is isolated because the primary and secondary grounds are different nets; they are only connected with a safety capacitor.

Other standard isolated power supply topologies are shown below. These are only topologies; a gate driver is also needed to drive switching action. A feedback mechanism is also used in real isolated power supplies; the feedback circuit measures the output and adjusts the driving PWM signal is used to maintain a target voltage.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

One point to note about the above topologies is that the circuitry could be partially or totally integrated into an integrated circuit. These integrated circuits provide high galvanic isolation, but with integrated feedback and supporting circuitry needed for low noise. They are more common for use in low-power systems that require low noise and high efficiency.

Transformers Provide Galvanic Isolation

An isolated power supply uses an isolation transformer to provide galvanic isolation between the input and output sections. Transformers simply transfer power between coils using the magnetic field generated by an alternating current in each coil, and the voltage is stepped either up or down, depending on your turns ratio in the transformer. The benefit of isolation with a transformer is that there is no direct electrical connection between the input and output coils on the transformer; the conductors on each side do not touch each other. Power is transferred across the two ground regions in the device via induction. This keeps anything downstream of the transformer protected from high voltage/current on the input side, or, in other words, everything downstream is ‘isolated.’

When a feedback loop is needed for monitoring and control over the output power, an opto-isolator is normally used to link the output back to an earlier regulator stage. This component uses an infrared diode to ensure isolation between high power and low power regulator stages. For power supplies that run at low voltage / current, an opto-isolator can usually be connected directly to the output, although there are some opto-isolator ICs that can receive larger voltage / current levels.

One point to consider in an isolated power supply is its efficiency. All transformers have some losses, both in the form of heat dissipated in the winding and due to alternating magnetization in the core. The magnetic material used in the core (usually iron or a ferromagnetic alloy of iron) becomes magnetized back-and-forth as the input AC current oscillates. When the magnetic field created by the AC input is very large, it can cause magnetization in the core to saturate, which limits the output power (decreases efficiency) and creates greater core losses. This is one of the factors that determine primary voltage ratings on the two sides of the transformer.

This type of transformer might be found in a large isolated power supply.

Isolated vs. Non-Isolated Power Supply

Now that we know what isolates a supply from your board, it becomes rather obvious that taking the transformer out of the design chain suddenly makes it a non-isolated power supply. Designing a board without power isolation is common, however if you are working at high power or you are using a fast switching supply, consider the end-user along your design journey, as you might just save yourself a court case or two when your favorite customer receives a shock they won’t soon forget.

The upsides of designing these non-isolated power designs are plentiful. First, you’ll enjoy more board space relative to an isolated power supply design due to the fact that you won’t need to put a transformer in your enclosure. There are small off-the-shelf transformers for lower voltages/currents, but as you scale up you gain more board space. You'll may also benefit from increased efficiency with a non-isolated power supply.

Non-Isolated supplies always hold the risk of electrical shock through the design.

It is worth noting that it is common practice to place non-isolated power regulator downstream of an isolated power supply or isolated switching regulator. In this strategy, the isolated power supply is placed at the high power AC or DC source, which then drops the voltage down to a level that is safe enough for a standard DC regulator IC or voltage regulator circuit. This is a bit more complex, but it has the advantage of giving you the proper protection that checks off your safety requirements. An example of this may look like a standalone medical power supply (isolated) that feeds a handful of devices (non-isolated) downstream.

Which One Is Right For You?

In summary, typically the power regulation circuit on your board will simply be a non-isolated power supply. These are built from small regulator circuits or chips that do not require isolation because they may not be generating much current or operating at very high voltage. Even if they do operate with high current, the user may not ever interact with the system in such a way as to be at risk of shock. Therefore, non-isolated supplies are just fine for the majority of smaller boards. This will usually just be a buck converter followed by an LDO to regulate power down to the required level.

When you need high power AC to DC conversion, or high power DC to DC conversion, you'll generally use an isolated supply, and many times the power supply will be designed on its own board. What happens next depends on the particular characteristics of your power source (AC vs. DC, mains vs. battery, etc.), how your enclosure will be used, and how ground is defined in any downstream circuits or systems connected to your power supply.

As previously stated, isolated power supplies are often required for regulated industries and must perform to certain standards. Examples include:

- IEC 60601-1 safety standard for medical devices

- IEC 62368-1 for IT and AV equipment (replaces IEC 60950-1 and IEC 60065)

- IEC 61204-7:2016 for general switched-mode power supplies.

Some regulations do not specify certain industry standards (for example, US FDA regulations on cardiovascular devices in 21CFR870.3605), but they do mandate safety and EMC testing to ensure these devices will be fully compatible with other electronics and basic safety standards in their intended environment.

If you've decided on an isolated vs. non-isolated power supply for your next system, Altium Designer® has the circuit design and PCB layout tools you need to create your next product. Altium 365™ delivers an unprecedented amount of integration to the electronics industry until now relegated to the world of software development, allowing designers to work from home and reach unprecedented levels of efficiency.

We have only scratched the surface of what’s possible with Altium Designer on Altium 365. Start your free trial of Altium Designer + Altium 365 today.