How Multi-Level BOMs Can Organize Your Next System Design

Table of Contents

If only packing for vacation were as simple as it sounds: figure out what clothes you need, throw them in a suitcase, and you’re ready to go—wrong! Here’s the more realistic vacation planning scenario: pack your clothes, pack your children’s clothes, and then pack all the other personal necessities such as diapers, games, etc. Next you need to pack the food followed by whatever gear your particular vacation requires including tents, fishing equipment, etc. Finally you are ready to pack it all into the car, and hope all those years playing Tetris pays off with it all fitting in the car. Oh, and don’t forget the dog.

The only way that I have found to successfully arrive at our destination without forgetting anything important is to be organized with packing lists. That means everyone has their own list to manage, and I have the master list to bring it all together. If this structure sounds familiar, don’t be surprised—it is exactly how a system level multi-level bill of materials (BOM) for printed circuit boards works.

If you haven’t worked with a multi-level BOM before, let me take you through some of the highlights. We’ll talk about how a multi-level BOM is different than a regular flat BOM and some of the challenges that go along with it. Then we’ll look at ways to help you manage and work with a multi-level BOM and how it can ultimately benefit you.

What is a Multi-Level BOM?

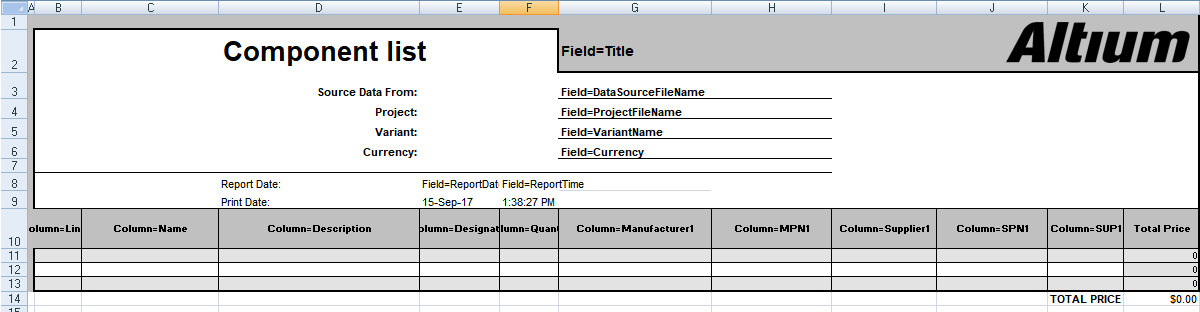

A PCB BOM lists the components needed to assemble a circuit board as individual line items. The components are usually listed in the BOM by their company part numbers, followed by quantities, reference designators, and general descriptions. There may also be additional information listed such as the component tolerances and values, or the physical footprint used by the component on the board.

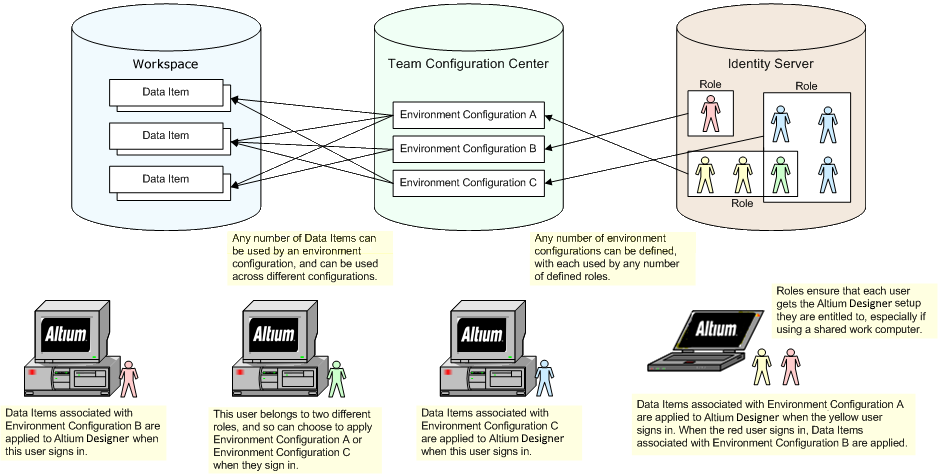

A multi-level BOM, which is also known as an indented BOM, works the same way except that it is at the higher system level instead of the lower individual PCB level. In a multi-level BOM each PCB used in the system is listed as a sub-assembly, and each PCB sub-assembly contains all of the regularly listed PCB BOM contents. The concept is similar to a hierarchical schematic where you can see all of the functional areas of the design represented by block symbols on the top sheets.

Problems Managing a Traditional Multi-Level BOM

Multi-level BOMs have been in use for a long time and are typically managed manually. As an example, let’s take a simple master design that has a controller board and a power supply board within it. You would extract the individual PCB BOMs from both CAD databases and then combine those BOM’s into one master spreadsheet for your multi-level BOM. Since this is a manual editing process, there are some potential risks:

-

Manual editing can lead to input errors: No matter how careful you are, there is the possibility of introducing errors into the master multi-level BOM. You may make a selection error when cutting and pasting, or a typing error when inputting the data.

-

The two sub-assembly BOMs are not connected: When you create the two separate BOMs, there isn’t any electronic connection between the two designs. This forces human verification to make sure that both BOMs and their designs are using common components to lower manufacturing costs.

-

Parts may not get updated across both sub-assemblies: Without an electronic connection between the two designs, parts that are updated in one may not be flagged for updates in the other.

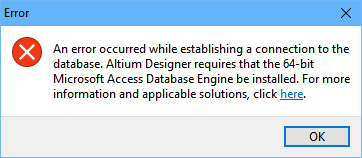

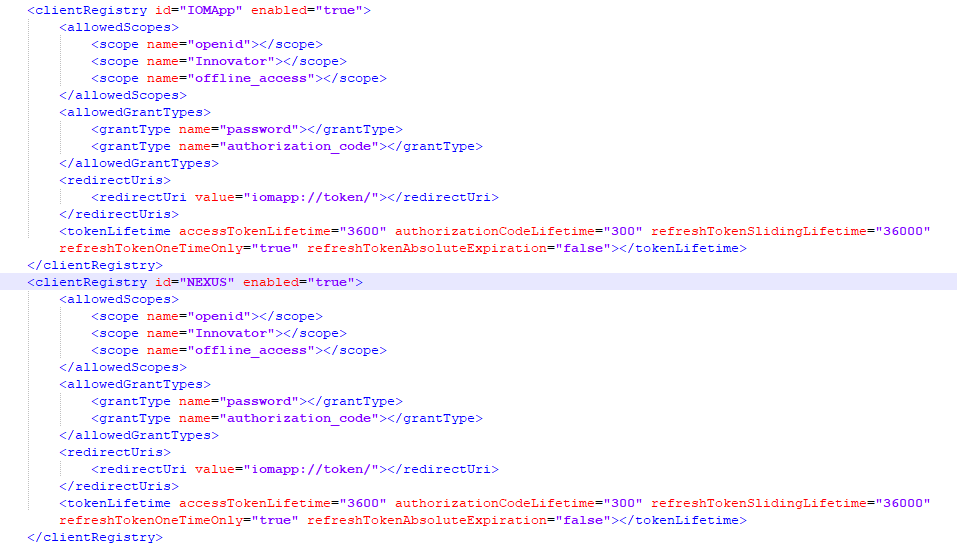

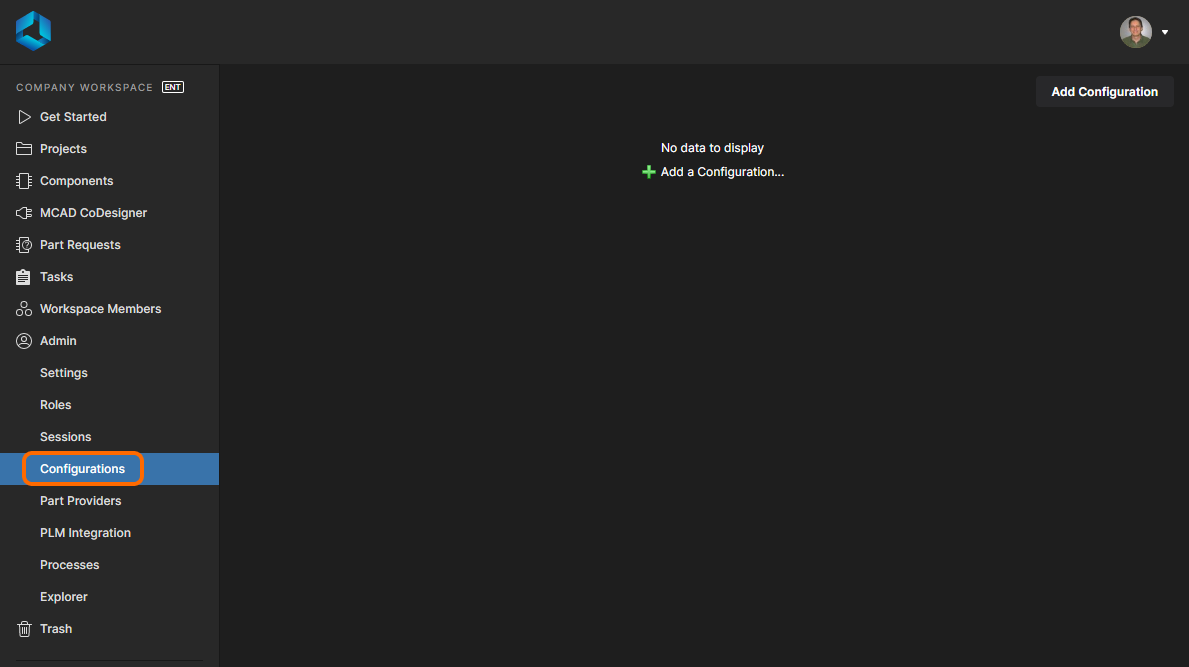

BOM Tools Can Help with Multi-Level BOMs

The good news is that today’s bill of material management tools can help you with the creation and management of multi-level BOMs. With online BOM tools you will be able to add individual PCB BOMs as sub-assemblies into a master multi-level BOM. This will give you the following benefits:

-

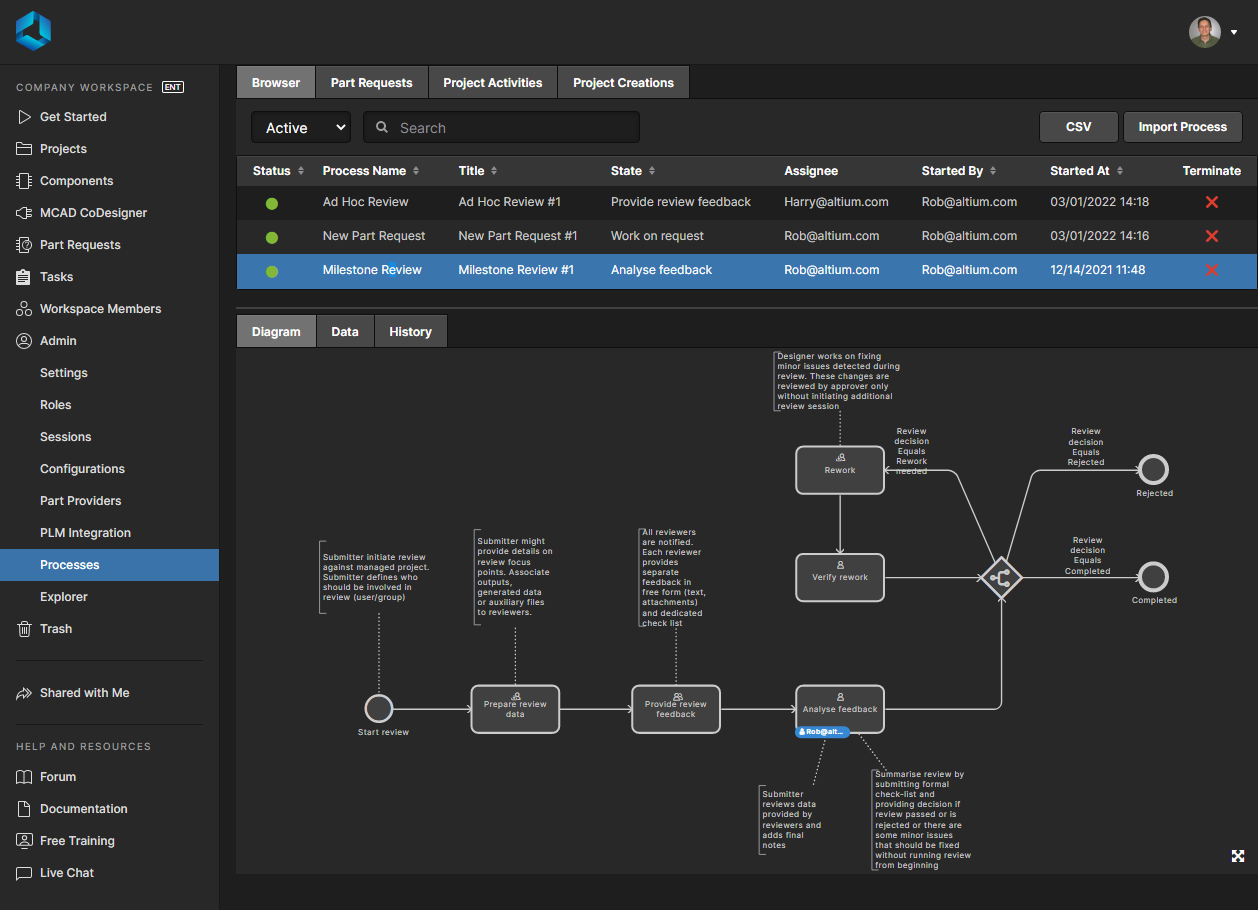

The multi-level BOM is created by the online tools: When you create a multi-level BOM, the work will be done by the BOM management system. You will no longer have to worry about potential errors created by manual editing.

-

The separate BOMs are connected electronically: Once you have added the separate BOMs as sub-assemblies, they are now connected together in the master multi-level BOM. This will give you the ability to compare components through the system to verify commonality of designs.

-

Online BOM tool functionality works across all sub-assemblies: With functionality such as part life-cycle and purchasing built into the online BOM tools, you will be able to manage the parts across all sub-assemblies. For example, when a part is flagged for needing an update, it will be flagged in all sub-assemblies.

-

Sub-assemblies can be pulled out for manufacturing: If required, sub-assemblies can be pulled out of the main multi-level BOM as an individual BOM and sent to a different manufacture.

-

Sub-assemblies can be modified individually: Sub-assemblies can be changed out with other sub-assemblies for updates or corrections.

What used to take a lot of time and careful checking can now be done online by simply pointing and clicking to add separate BOMs into one multi-level BOM. Fortunately, packing your multi-level BOM using BOM tools doesn’t have to be as frustrating as your vacation packing. The creation of a multi-level BOM with BOM management tools can help your BOM creation process by speeding it up—and making it less vulnerable to error.

Don’t suffer through packing your multi-level like the old Wagon Queen Family Truckster for vacation. Use Altium’s BOM tools, and find out more information by talking to an expert at Altium.