Semi-Additive Process Technology at Averatek

In today’s OnTrack Podcast Judy talks to Mike Vinson, the COO of Averatek about their breakthrough innovation in which they use a semi-additive process incorporating a liquid metal ink as the catalyst seed layer. This special catalytic precursor “ink” can be imaged to create the patterns or areas where conducting metal is to be deposited. This ink controls the horizontal dimensions of line width and spacing and creates the ability to get down to 1 mm and sub-1 mm line and traces. Keep an eye on this technology!

Listen to the Podcast:

Download this episode (right click and save)

Watch the Video:

Show Highlights:

- Mike’s background is in semiconductors primarily in the area of interconnects.

- At Averatek they create HDI solutions.

- What does Averatek’s technology enable engineers and product developers to realize? Lower layer count, Improve Yield, Cost reduction and High Value

- What is Semi-Additive Process Technology? Fundamentally the ink carries plating onto the surface of the substrate, depositing them in very thin layers.

- Also called atomic layer deposition - Averatek calls it lipid metal ink.

- Process allows for very precise and very small circuits.

- Learn the jargon: SAP (Semi-Additive Process).

- Copper can be left undisturbed by the etching process.

- Can be run in a traditional board shop - new technologies are emerging.

- Lithography capital equipment is indeed a worthwhile investment.

- Liquid Metal Ink where are you in getting this to market? Strategy is to license and sell liquid metal ink.

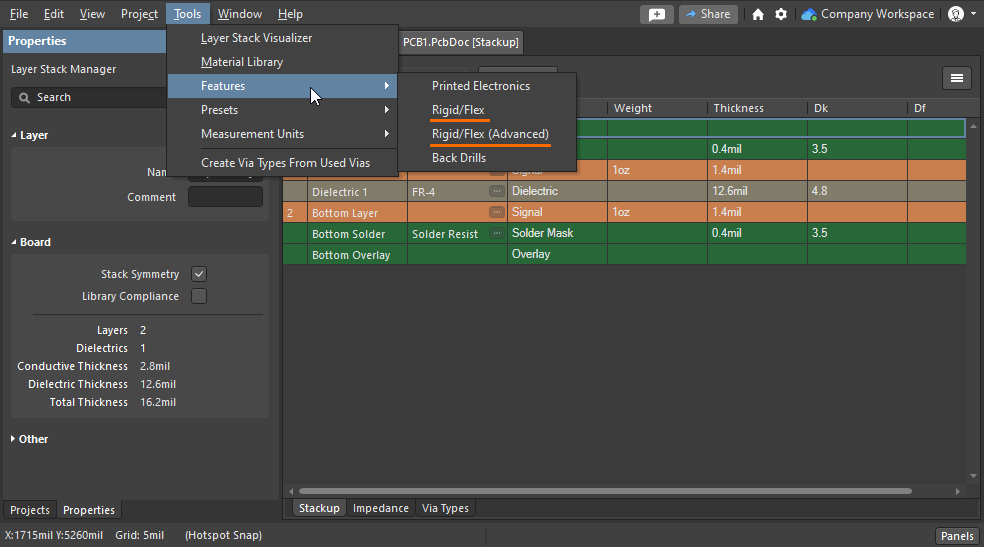

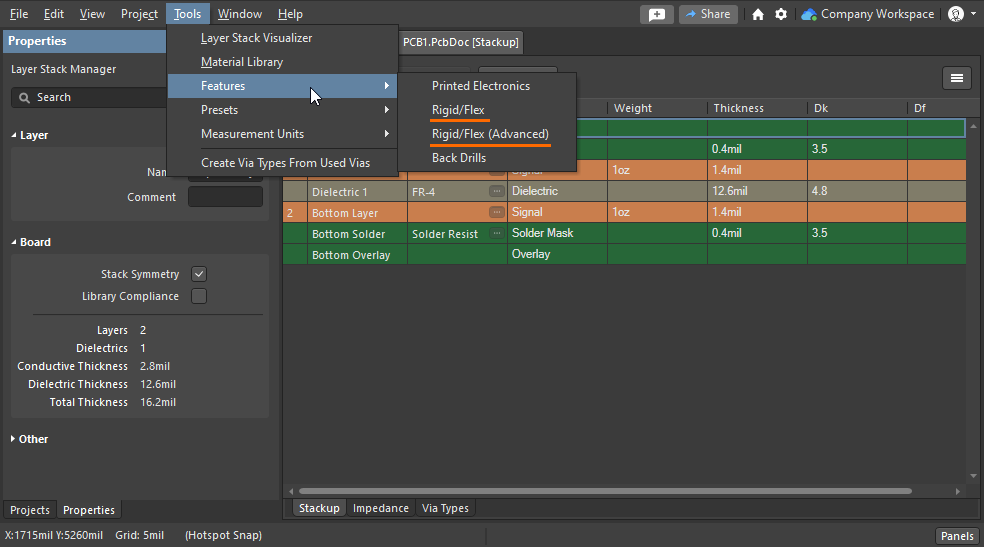

- What type of design considerations will EDA tools need to build-in to enable design with this technology? Smaller lands and increased density.

- Evolution: Lines & Spaces first then other areas.

- Thieving areas parameters will change.

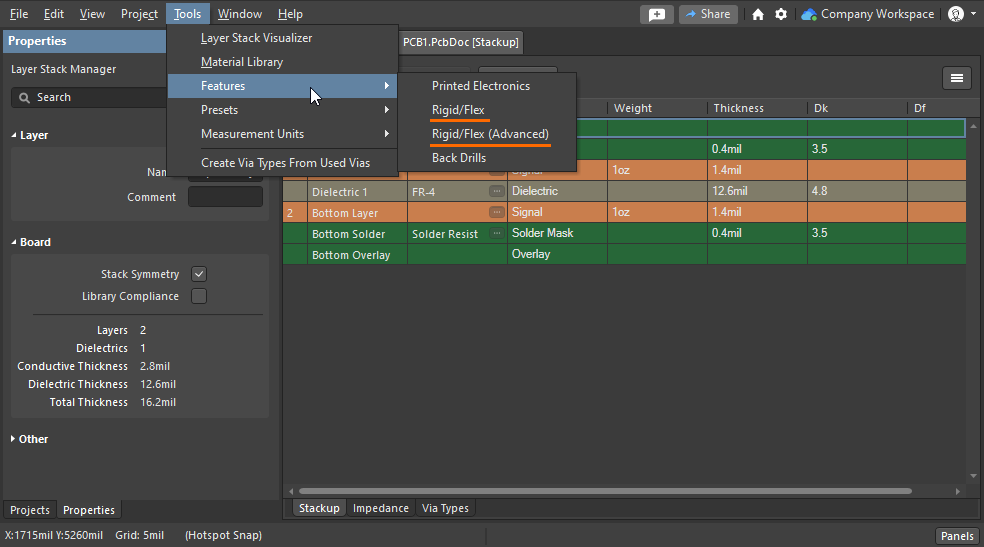

- This tech will work for both flex, rigid-flex, and rigid circuits.

Links and Resources:

Email: mike@averatek.com

Preview to Apex - this was both Mina and SAP and mSAP focused

Additive Electronics PCB Scale to IC Scale

Flex Circuit Firsts - mentioned Averatek

Medical research is Golden - additive process and gold conductors

Trade In Your Outdated PCB Design Tool & Unlock 45% OFF Altium today!

Click here to view all Episodes

Or click here to access the Altium Free Trial Today.