5 Advantages of Z2Data Integration You Can't Ignore

Managing component sourcing and supply chain issues is a constant challenge. With risks like natural disasters and part obsolescence rising, finding a solution that simplifies these processes is crucial. Z2Data Integration in Altium 365 offers a practical way forward, providing clear advantages for designers and procurement specialists. This blog post outlines the top five benefits of Z2Data Integration, showing how it can streamline your workflows.

Stormy Seas of the Electronic Components Supply Chain

You’re already familiar with some of the challenges in the electronic components supply chain and how they impact your ability to deliver products to the market. But it’s important to understand that the risk of disruption is not just growing; it's evolving, becoming more complex and costly with each passing year.

The number of natural disasters per year that have cost over $1 billion in damages has surged by 150% in the last four decades. Additionally, over the past two years, the situation has become even more dire, with over 800,000 parts becoming obsolete.

This obsolescence, coupled with the increasing variety of disruptions, from environmental catastrophes to geopolitical tensions, poses a significant risk to the uninterrupted flow of your supply chain. According to a Gartner study, while 95% of supply chains are required to adapt swiftly to these challenges, only a mere 7% possess the agility to do so effectively.

The implications are clear. As the landscape of disruptions widens, selecting the right components for your products becomes an increasingly complex puzzle. Choosing parts based solely on their form, fit, and function is no longer enough. Today's pressures demand that you consider a broader spectrum of factors, from lifecycle forecasts and compliance requirements to manufacturing regions and technological advancements.

And this is where Z2Data Integration in Altium 365 steps in as your indispensable partner, offering solutions that navigate you through these turbulent waters, ensuring your product not only reaches its destination but thrives in the market.

Who Is Z2Data

Z2Data, based in Santa Clara, Silicon Valley, offers a practical approach to product risk management, drawing on over two decades of industry experience from its founders.

This platform is designed to directly address the challenges of supply chain disruptions, providing targeted solutions from the design phase to the final delivery.

Z2Data utilizes AI and machine learning technologies, supported by detailed databases on parts, supplier relationships, and global manufacturing locations, to help businesses make informed decisions and effectively mitigate risks.

Pains of Manual Data Searches

To fully grasp the full potential of Z2Data Integration in Altium 365, let’s first focus for a moment on the daily challenges of manual data searches.

Picture the countless hours spent navigating through multiple databases, the frustration of cross-referencing outdated spreadsheets, and the constant battle against the clock to find the most current, accurate information on component availability, pricing, and compliance. This tedious process not only drains your team's time and energy but also poses a significant risk of errors that could impact your project's budget and timeline. Have you been there?

This Is the (New) Way

Now, imagine a solution that streamlines this process, ensuring you have immediate access to the data you need, when you need it, directly within your design environment.

This is the way Z2Data Integration transforms the complexities of electronic component procurement into a smooth, efficient, and accurate process for Altium 365 users.

Advantages of Z2Data Integration

Z2Data Integration brings critical data directly to your fingertips, transforming how you access and utilize information. By integrating with your existing workflows, it simplifies electronic component management and enhances decision-making with insightful guidance. Explore the tangible benefits it delivers to your operations.

#1 Integrated Data Accessibility

Forget the days of laborious searches through external databases. Z2Data integrates critical component and compliance data directly into Altium 365, streamlining your processes and enhancing productivity.

#2 Instant Supply Chain Insights

Stay ahead of the curve with real-time monitoring of your Bill of Materials (BOMs) for potential risks, from obsolescence to geopolitical threats. Z2Data Integration provides timely alerts and mitigation strategies, ensuring you're prepared rather than caught off-guard.

#3 Simplified Parts Sourcing

Finding alternative parts shouldn’t be a struggle. Z2Data's extensive database, featuring real-time lead times and pricing, supports easy part replacement, keeping your projects on track.

#4 Proactive Risk Management

With Z2Data insights, anticipate potential disruptions and market fluctuations. Access actionable forecasts and strategic planning tools to navigate future challenges, safeguarding your projects from unforeseen setbacks.

#5 Data-Driven Compliance

Rely on Z2Data for high-quality, curated information that ensures your product adheres to all relevant regulations and ethical standards. This integration not only builds trust but also significantly reduces compliance risks.

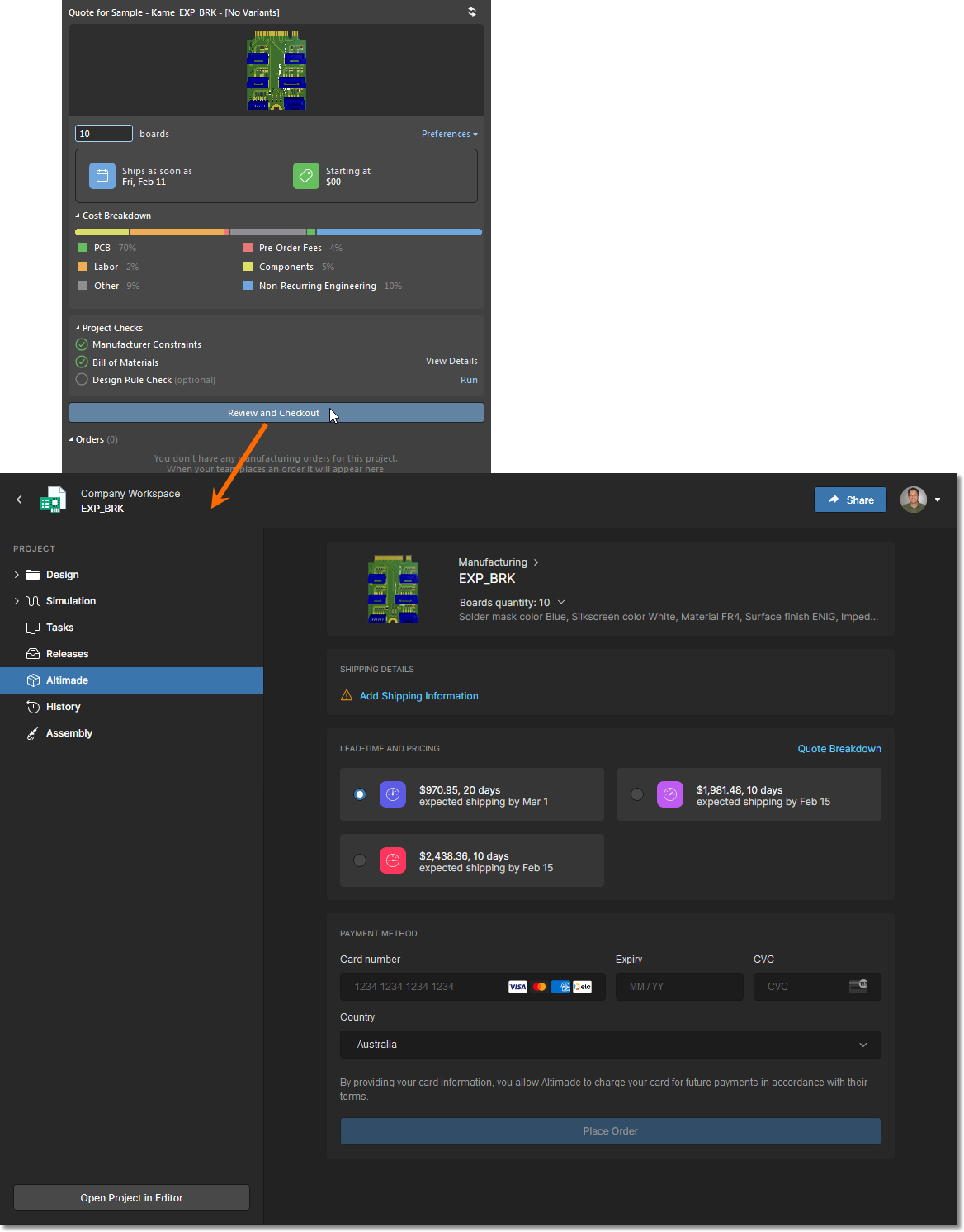

Z2Data Integration in Altium 365

Okay, so you know the value. But what exactly does this integration look like, and how does it function within Altium 365?

- Real-Time Lifecycle and Risk Analysis in Altium Designer BOM

Engineers can access comprehensive part research directly within Altium Designer BOM, including lifecycle compliance and other crucial factors, ensuring the selected components fit perfectly within the schematic and won't cause future production issues due to obsolescence or short market lifetimes.

Beyond initial part selection, Z2Data Integration offers an in-depth analysis of existing BOMs, providing up-to-date insights on component lifecycles, risk, and compliance. With the ability to add real-time data columns to your BOM, Altium 365 automatically highlights and helps you address potential issues early on.

- Real-Time Lifecycle and Risk Analysis in WebViewer

Z2Data Integration extends its capabilities to Altium 365 WebViewer, allowing team members outside the core engineering group to get access for real-time BOM reviews and collaborative decision-making on part-sourcing issues, with the ability to add comments or assign tasks for replacements or alternative selections.

Again, you can customize the BOM view by adding new data columns. Activate additional data points with a simple click, pulling live data from Z2Data web services.

- Simplified Manufacturer Part Search

Accessing the Manufacturer Part Search panel allows you to swiftly locate the component you need using manufacturer details, keywords, or filters. With a simple click, you're able to validate your chosen part against the Z2Data comprehensive information database.

While Altium 365 provides basic lifecycle information and parametric data, Z2Data integration enriches this with deeper insight. You gain access to additional fields such as parts score, lifecycle, lifecycle forecasts or years to end of life (YTEOL), compliance risks, market trends, and more.

Additionally, Z2Data Integration suggests three alternatives for the part in question, making sure your project remains on track.

- Informed Decision-Making in Company Library

Within Altium 365, you'll find that the Z2Data Integration enhances various interfaces, such as the Components Panel, Explorer Panel, Components Editors, Schematic Properties Panel, and more. These enhancements allow you to quickly verify the current status of any component in your library with just a few clicks. Whether you're assessing lifecycle stages, checking for updates, or evaluating component specifications, Z2Data Integration provides a seamless and efficient way to access the information you need.

- Comprehensive Library Insights in Web Interface

Z2Data Integration also enriches the Altium 365 web interface with detailed insights into your library's components. You can access a library browser interface to navigate to specific component pages. Here, you'll find up-to-date information on the lifecycle and risk analysis for your selected part choices, all without the need to open Altium Designer. This capability ensures that every member of your team, regardless of their role or access level to the design tools, can review and assess critical component data directly from the browser.

- Customizable Integration Settings

Z2Data Integration interface allows you to tailor its settings to suit the unique needs of your project.

Learn More

Managing the electronic components supply chain requires a smart approach, and Z2Data Integration in Altium 365 delivers just that. By using this integration, you gain access to features that make your workflow smoother, improve decision-making, and ensure the accuracy of your data. To learn more about these benefits, visit our product page.