Hands-On with Altium 365's New BOM Portal

In this episode of the OnTrack Podcast, we explore the innovative BOM Portal in Altium 365, a cutting-edge tool transforming PCB design and electronic development. Tech Consultant Zach Peterson sits down with Ananth Avva, General Manager at Altium's Cloud Platform, and Damir Khayrutdinov, Product Manager at Altium, to discuss the tool.

Altium's BOM Portal, compared to ActiveBOM, offers a seamless and efficient approach to managing bill of materials (BOM) throughout the product lifecycle. We dive deep into the capabilities and features of the BOM Portal, including its integration with various CAD tools and its role in streamlining design-to-realization processes. Learn from our guests about the trends and challenges in electronics development and how Altium Designer 24's BOM Portal addresses these issues.

Key Highlights

- Discussion on trends in electronics development

- Reasons for building the BOM Portal on Altium 365

- Challenges in BOM management and how the BOM Portal addresses them

- Insights into the relationship between ActiveBOM and the BOM Portal, how it works, customer response, future developments, multi-board systems, and the future vision for Altium 365

Resources and Links

- Follow Ananth Avva and Damir Khayrutdinov on LinkedIn

- Learn More about BOM Portal Here

- How to 'Shift Left' and Connect Procurement and Engineering? Altium 365 BOM Portal Step-by-Step

- BOM Portal Webinar

Listen to the Episode

Watch the Episode

Transcript

Zach: Some of the features that you just mentioned sounds a bit like ActiveBOM in Altium Designer and I think the more experienced Altium Designer users out there will notice this. So, how exactly does this new tool compare with ActiveBOM? Does it replace it or does it complement it?

Damir Khayrutdinov: Yeah, it's a good question. ActiveBOM is a BOM tool what was designed to help engineering team release design BOMs with all needed information and capabilities such as adding alternates, line numbers, custom lines, et cetera. And seems it works well based on level of adoption and user feedback. However, it's embedded into the design tool, Altium Designer.

Zach: Hello, everyone. Welcome to the Altium OnTrack podcast. I'm your host, Zach Peterson. Today, we're talking with Ananth Avva, General Manager of Altium's cloud business and Damir Khayrutdinov, Product Manager at Altium. We're gonna be discussing one of the new features in Altium Designer 24 and that feature is the BOM Portal. I got to see a short demo of it before this episode and so I'm very excited about this new feature and I hope all of you will be as well. Damir and Ananth, thank you so much for joining me today.

Ananth Avva: Yeah, likewise. Great to be here, Zach.

Zach: So, what are some of the trends and problems that you're seeing in the electronics development space, Ananth?

Ananth Avva: Yeah. So, I think the common root cause is the velocity of the actual development process continues to accelerate and the proliferation of electronics as everyone probably listening to the podcast, they're no stranger to that. But I think that's the root cause but the symptoms show up and I would say in three different areas. The first one is, sort of, mapping requirements and intent to the actual design. So, when you start going from functional to physical to actually the layout, are you actually bringing those requirements all the way through, right? The second one, while in the post Covid era, we've seen supply chain, et cetera, settle down. Supply chain, and also just compliance for components 'cause that's still about 40% to 70% of what you're building is a big area of focus especially as we're getting into whether it be geopolitical tensions in the Red Sea, all the way to trying to understand your actual full traceability of where the components coming from down to the fabrication plant. So, that's a very big area of focus, especially for our aero military customers. The third area, I would say, is getting into some of these emerging themes like sustainability and getting down to what is the footprint of what I'm making and 80% of, sort of, the sustainability aspects is done in design. And so, bringing some of those thoughts, especially when you're thinking about your BOM and you're thinking about, sort of, orchestrating your entire supply chain, that's come up and starting to come up, especially with DPP requirements coming in Europe. And lastly, it's the collaboration with manufacturing. So, we deal a lot for obvious reasons with designers and that handoff process and making sure that the manufacturers and the components that they're selecting versus what was in design and then people are moving lockstep. That continues to be a big focus. But all of these four areas are sort of the symptoms but the root cause is, again, just the velocity with which development's happening.

Zach: Well, given the velocity that you've mentioned, it sounds like that was part of the motivation behind building a lot of these new features in Altium Designer 24. So, what was the motivation behind building the BOM Portal on Altium 365?

Ananth Avva: Yeah, I think with Altium Designer, I mean that's obviously where we have our design audience, but we wanted to build a front end where other folks can come in and start collaborating and very specifically, your component, sort of, manufacturing personnels or even the masses where they're able to actually get that visibility. I think of, sort of, that BOM as the first, sort of, physical manifestation where the design is actually born, right? You're in the design to realization space, that's the first front end that everyone can actually look at and collaborate on. And so, the motivation for doing this in the cloud and basically having this sort of abstraction layer out of AD because one of the key things is, the BOM Portal, while, you know, it's highly functional and highly integrated into Altium Designer, it's mixed CAD. So, we'll actually work with all the CAD tools. And so, we really wanted to make sure that we have that one front end where it's not just for designers but it's also for all of the other satellite professionals that they touch and they're able to come in and collaborate to ensure all the issues that we just talked about in the electronic development process. We have a way to mitigate those risks and have those participants come in and basically get that view and also basically get the ability to edit and collaborate on the design itself.

Zach: So, since we're here to learn a bit more about the BOM Portal tool, Damir, maybe you can tell us what are some of the BOM management challenges that you've seen across the industry that inspired your team and the development of this new tool?

Damir Khayrutdinov: In addition to the standard challenges and BOM and supply chain management for electronics such as chip shortage and second sourcing, we noticed that the processes and tools used for that are mostly from 90s. Most still use Excel files and emails for that. So, to get the PCB BOM ready for ordering, the procurement team works with exported Excel BOMs. This process typically involves four, five emails with collaboration about three or four contributors who are responsible to make decision. Yeah. So, this takes time to interact and because of the friction happens later in the process, cost of the work, time and money wise, is more expensive. Of course, there are companies who well adopted with POM MRP and the ERP systems, but even the company implemented such systems, the level of its adoption is different. So, we track the cases when engineering use POM PDM, but procurement still works with Excel, shared drives, et cetera. Another common problem is fragmented approach to accessing and analyzing technical specifications, compliance information and supply chain data. Typically, procurement expert quality engineers and compliance specialists have to navigate through multiple platforms to gather necessary details about parts. The result in scattered data, yeah, manage it across different systems, often leading to limited access to all of these team members. And we can talk also about product teams and OEM specifically. For such teams, the BOM management is not finished once the BOM is released. You should be aware of the manufacturability of your released PCB BOM during the end customer warranty period or product production cycle, which might be not just a few weeks or years. So, for such teams, BOM management is an interactive process that is time consuming and error prone due to constantly changing supply chain. For such teams, the manufacturability is a function of a time. So, the release BOMs needs to be constantly monitored. And in order to manage that, most of the teams still use manual processes for that which is not so effective. So, I would highlight these three common challenges which are at across the industry.

Zach:Yeah, you mentioned Excel files and emails. I will admit I'm guilty of that one, but I think it's because of the lack of anything better and everybody else does it. So, you're kind of shoehorned into doing this because there just hasn't been anything better really. So, given all of those issues that you brought up, how does BOM Portal help solve some of those challenges?

Damir Khayrutdinov: Yeah. In short, the BOM Portal helps to take advantage of rich parts and supply chain information to scrap BOM and identify risks from multiple angels. It might be availability, it might be cost, it might be compliance, second sourcing, et cetera. Next is the collaboration aspect, which is, I would say, one of the core features of the A 365 platform. So, with the BOM Portal, you can get the advantage of constant platform for engineering and procurement team in one, so no exported files without context anymore and you have a common collaboration process in one. And third, I would say that we didn't really use it, but it's a parts watchdog feature which is currently in the closed beta, but it helps to deduce supply chain risk and ensures continuous production by proactively tracking and providing warnings for supply chain issues, prompting timely action to avoid any disruptions. Of course, we still offer parts traceability or we call it very usage which simplifies the identification and assessment for potential absolute issues. So, these three things.

Zach: You know, some of the features that you just mentioned sound a bit like ActiveBOM in Altium Designer and I think the more experienced Altium Designer users out there will notice this. So, how exactly does this new tool compare with ActiveBOM? Does it replace it or does it compliment it?

Ananth Avva: Yeah, it's a good question. ActiveBOM is a BOM tool what was designed to help engineering team release design BOMs with all needed information and capabilities such as adding alternates, line numbers, custom lines, et cetera. And seems it works well based on level of adoption and user feedback. However, it's embedded into the design tool, Altium Designer. And ActiveBOM has a strong dependency on the design data. So, in order to use it for procurement, you need to share design, all design and provide access to the design tool. Next is that it helps on the design stage but not beyond it. For example, you can create the ordering from multiple PCBs which need to be assembled. It's also not effective to use in a production stage. For example, in order to add additional alternates suggested by your contract manufacturer, you need to release the wall design in ActiveBOM. The BOM Portal is designed to support BOM management in all electronic product lifecycle stage. So, in addition to the generic BOM tool capabilities for scrapping, it includes capabilities need to control obsolescent for the released boards, compliance management and part search capabilities, especially for alternate search. So, it's definitely not just a BOM tool, not just a BOM editor as ActiveBOM is.

Zach:So, if we could, let's dig into how the BOM Portal works. Can you make this a bit more tangible for our listeners.

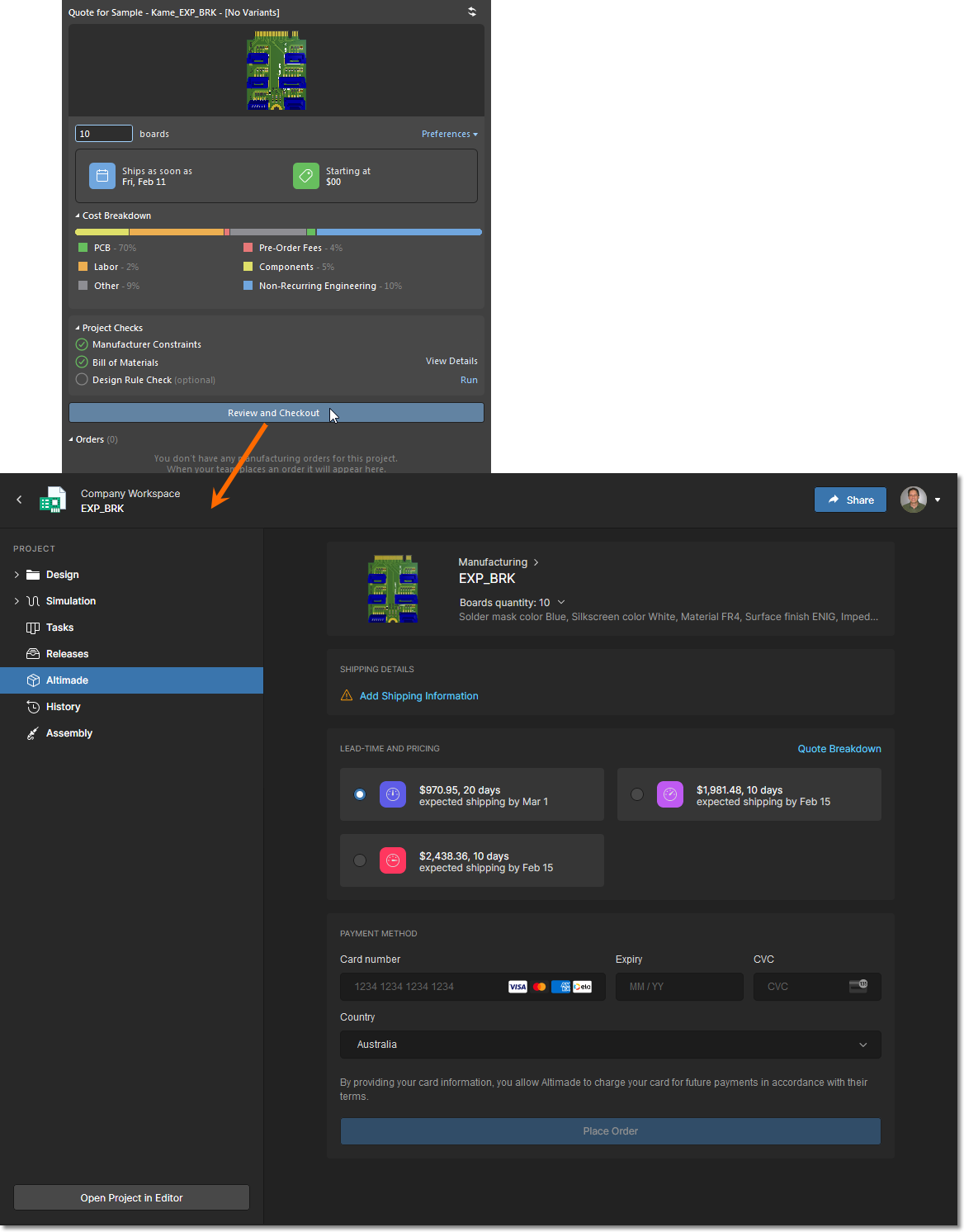

Damir Khayrutdinov: As I mentioned, the BOM Portal provides benefits for the different roles and support BOM management in all lifecycle stage. We can start from the early design stage where BOM Portal can speed up the process of prototype BOM scrubbing and preparing it for purchasing. I can share my screen and just share how it works.

Zach: So, we're looking at Altium 365 right now and I see a bunch of projects you have on screen.

Damir Khayrutdinov: So, I have this proto design. It has just version 1.1. If I open it, it'll open it in a separate tab. I believe you still see it. And here is a viewer, online viewer, which is available in A 365. There is schematic viewer, PCB viewer and of course, bill of material. And as you can see, engineering was focused only on critical parts. So, there is no any part numbers specified for generics such as capacitors or resistors, et cetera. And in order to prepare it for purchasing, we have the capability to create a managed BOM from the design and scrap it without touching of engineering data, which might be critical for some cases. Yeah. So, once I click to create a managed BOM from design, procurement is able to select what ORM should be used. We also support it. And once the bill of material will be created, it'll be stored at the same folder as original design. So, it takes a minute. Yeah. So, we can refresh the page and here is my BOM which I just created. If I click on the original design, you will see that now I have a child BOMs and link to this procurement BOM created from the design. So, let's open this bill of material. And what we see? We see exactly the same bill of material what was created by engineering, but for the part numbers which are not specified, we see this lamp icon which means that exact map is not defined and it's true. We don't have exact part number for this BOM line, but BOM Portal try to analyze all information about this BOM line, about this component, and it has some suggestions. So, if I click on this lamp, you see that BOM Portal suggested multiple parts which has parameters specified in BOM line and they are colored with green. In order to see all parameters, we can switch to the advanced parametric search and we see what data is actually was analyzed and used in order to help engineering work with procurement actually find parts. So, you will see that BOM Portal analyzed designator and description and track that this is capacitor. The capacitance is 100 nanofarad. We detected voltage rating, we tracked the case package and we have suggestions. As a procurement, I will pick up just a component which is in stock with minimum order quantity which is also shared here and in stock. Yeah. I would pick up this one. No, it's not a good because we have not recommended for new design. I will pick up this one and click Use. In this manner I can scrap all my BOM and also, I can even improve it. You see that there is one part which was specified by engineering has obsolete lifecycle state. Maybe it's good for the prototyping because this part is in stock et cetera. But as procurement I will try to find alternate and just notify engineering that there is another component available in the market. And how I will do this and how BOM Portal help me is that we have try alternate search mode which provide alternates specifically found for this original part number and we have confidence core which means that from this information, you can understand how this part is compatible with the original one. So, this is how BOM Portal can speed up the process on BOM scrubbing for proto BOMs. And other case, what I would like to share with you is prepare BOM for production run. For this, I have this bill of material which is available in my- Yeah, I just exported it to Excel file. It has just a few columns, designator, quantity, manufacturer and MPN and some of the BOM lines have alternates defined. So, let's upload this Excel file into the BOM Portal and see how it will work with it. So, one second. Demo version 5. Yeah. Once this BOM file will be uploaded into the BOM Portal, it'll be automatically under the version and revision control as any other managed design, which is also a benefit for data management things. So, I have these BOM file uploaded. I open it in BOM Portal. BOM Portal ask me if there are alternates is defined? I will say yes because we don't know what exact means these lines which means designators. And here is it. So, we enrich. What BOM Portal did? It enriched the data which was available in the original BOM file. You see, the same four columns. But additionally, you can see all data provided by our data provider. So, in my case, I use pro-level subscription with SiliconExpert integration and I can use both of them in my BOM scrubbing. So, you can see that I have two lifecycle columns, one is getting from IHS Markit, another one from SiliconExpert. And for some cases, it's quite useful. For example, for this part, IHS Markit doesn't know about any- There is no any information about lifecycle, but SiliconExpert has it. Another example is with one of the challenges on scribing BOM for production run is adding alternates, is adding alternates to non stop production run on your contract manufacturer. And the BOM Portal has this capability to add alternates from different sources. For example, for this case, we will use alternates defined in my library, which means that it's company approved alternates. So, they were previously tested and approved to be used in my company. So, I will just click on add additional, add alternate online and we'll see all alternates, a little bit for this BOM line for this component. I see alternates from my library and I also see additional alternates which is coming from data providers. So, I will use this one. Next is, that usually, production run is not going for one or multiple BOMs. Yeah, you can have a production run with a thousand of boards and we can check is there any issues related to the production run to the number of production quantity. Yeah. Let's put 10,000 and check what we'll have. In issue step, I see that we have supply chain issues that some of the BOM lines have insufficient stock which might be also a problem for my production run. And how can I fix that? I have favorite suppliers and I see estimated BOM coverage coverage. So, I will just use additional suppliers here and we'll see that some of the problems have gone after that. So, right now, I see that out of stock only one part or insufficient stock only two. So, in this manner, we can scrap and prepare BOM for production run, and once it'll be ready, we can release it. And next, we can do comparison with original BOM files. So, these capabilities, it's not allowed in just in ActiveBOM tool. Yeah. And the last one what I would like to mention is how the BOM Portal can help for obsoleteness teams or quality teams. So, as I mentioned previously, we have this used parts report or parts watchdog, which is currently on beta. But what it can do? So, it grab all parts used in all my PCB BOMs and share risk information in one simple page. So, for example, I can be focused only for the critical parts and... One second. Yeah. I have this filter by component type. So, right now, I see all used parts in my workspace. I can filter out them by, for example, ICs and easily see what the status is for IC components in my workspace, in my products. One I see has discounted lifecycle states, and here, I also see in what projects, so I easily can identify what projects affected by this issue. So, this is how BOM Portal can help and speed up process on BOM scrubbing and help to mitigate supply chain risks.

Zach: So, you mentioned earlier one of the very interesting features is grading of alternates or replacements. And I have to be honest, that is something where I have spent a lot of time trying to find either an alternate source through a broker when something is out of stock or just a totally replacement part. And it's really hard to find something that will work sometimes that won't force you to go back in and change the PCB layout before you start producing something. So, I have to ask, are the replacements being graded based on pin compatibility or are there other dimensions that are being used to grade the replacements?

Damir Khayrutdinov: So, we utilize the supply chain data and parts data provided by allowed data providers. So, here we currently have Octopart, IHS Markit, SiliconExpert and soon, also Z2Data will be also supported. So, the confidence score provided by Octopart and IHS is just a basic rating from one to zero on how well a component will work as an alternate. SiliconExpert, however, provides a detailed grading system that evaluates component based it on various parameters. For example, rating A means that it's a pin to pin compatible replacement with exact electrical features. So, my answer is that depends on the data providers supported in your workspace, you will be able to use data providers, you will be use data provided by data providers uploaded to your workspace and alternates is also shared by these data providers. So, we have confidence score from our partners. So, it's not a data which was calculated on the file for example.

Zach: So, I have to ask what are customers saying about the BOM Portal?

Damir Khayrutdinov: One of the comments we have gotten from some customer is that BOM Portal allows them to replace their homegrown systems that needs custom development and maintenance. This shows us that we are really on the right track. Our customers already invested a lot to have their common custom solutions done. Still, this is not their core competency. Here, we are coming with as an electronic focused company with long history of successful software development. Another comment is that they want more meaning that we covered single BOM use case pretty extensively and now people wants to get multi-BOM use cases. We're working on the actively sought part reports I just shared with you and now we started project called Consolidated BOM which will allow users to optimize procurement for a given product, not just a single PCB board. Also, we would like to stress that we are really counting on customers feedback. We are proud to develop solutions to get positive feedback from our customers. It's not to say that we are fully bottom up as we do have a vision where we want to take the product, but we are bottom up enough to give our users flexibility they need. So, please to try BOM Portal and provide feedback so we can take this to the next level.

Zach: So, regarding your vision for this tool, what are some of the future developments that are planned for it?

Damir Khayrutdinov: The top end request is ability to work on a level of multiple BOMs versus a single board BOM. I already mentioned that we started project called Consolidated BOM. Another area is integration with ERP and POM, which is requested mostly by enterprise guys. And pretty constantly, we are getting requests about BOM review workflow. This is another example where our customers start developing their own solutions as there is nothing flexible enough on the market available.

Zach: Just to clarify something, you said multiple BOMs. Would that be for, like, a multi-board system?

Damir Khayrutdinov: Yeah. But I would just highlight that there is a case called consolidated BOM for ordering, when procurement expert needs to order parts for multiple BOMs which might be not used in one product. Yeah. You have separate PCBs just needs to be assembled. But another case is multi-board BOM, which is a part of the product. And this is a kind of next thread and it also in our roadmap, but it'll be implemented with a multilevel and multi-PCB BOM approach.

Zach: So, I have another question here for Ananth. We've spent a lot of time talking about and learning about the BOM Portal, but, of course, it is part of Altium 365. So, if you could, could you talk about the future vision for Altium 365 more broadly?

Ananth Avva: Yeah, absolutely. I mean, I think in the opening of the podcast, we talked about some of the areas of challenge and I think the goal for Altium 365 is to basically bridge the idea to realization processes, right? As evidenced by the BOM Portal, one of the first areas that we're focused on is bringing data and the right data in context. So, bringing the requirements in, so capturing the intent is going to come up here pretty quickly where we're going to have requirements tool that's specifically built for electronics. Those requirements then will automatically not just map into design but also start going into supply chain decisions. So, one of the questions that you had asked, Zach, on, well, is it going to a pin level? If that's a key requirement, we can actually make that as a trigger or a rule in the BOM Portal. And then, the next step is, obviously, then going into EMSS and tightening, sort of, our collaboration layers with EMSS where they can come in and engage. So, I think the first step that we're doing is building the right front end to have the common data layer that traverses, sort of, the decisions that are being made from start to the finish. The second is building a system of engagement on top of that system of record. So, what do I mean by that? All of these co-pilot/suggestion style interfaces that you're seeing with BOM Portal where we're reducing the cognitive load on whether you're a procurement professional or whether you're an engineer and actually ensuring that cognitive load is symmetrical, like, meaning just because I'm going to make a change or an engineer makes a change in the design, having the ability to either put cost constraints on them or vice versa, right, because you had to do something at the PCB level and the procurement team needs to know that now, the overall cost of the particular board has changed. Bringing those types of decision support tools and making this a system of engagement where people are actively collaborating to an outcome as opposed to just, sort of, for the sake of collaboration where you're getting visibility. That's something that we're working on and we're already seeing where for every, sort of, PCB designer that we have or for every two to three PCB designers. We have one non PCB designer coming into 365 and engaging. And this is everywhere from software engineers to mechanical engineers, to component folks, to procurement folks, to manufacturing engineers. So, bringing all those roles and bringing the right context in which they can engage, that's the second piece. And then the last piece is we have the system of record and you have the system of engagement. That's where context based AI applications become incredibly powerful, right? So, obviously, some of the things that we're looking at is, can you look at the data sheet and can you mine, sort of, the parametric information. The data sheet in terms of the quality assurance that Damir said where, yeah, there's third party tools like SiliconExpert that are doing it, but what about the right type of winning combinations, right? So, if you're going into a system level modular design, maybe, as you're building out the BOM and now that we understand the layout map, that we understand the functional requirements, we're now able to actually give you a suggestion on here's the right winning combinations, "that give you the best performance at the best cost" from a particular component manufacturer. So, a lot of what we're doing right now is, sort of, foundational to start building that system of engagement where folks are coming in and servicing the right front ends and reducing the cognitive load. And once we understand the behaviors and once we understand what's happening, we'll obviously bring more "AI based applications" that will continue to accelerate that.

Zach: So, this all sounds very exciting and I'm excited to see it all develop. Damir, how can anyone who is interested in all of this learn more about the BOM Portal and try it for themselves?

Ananth Avva: Yeah. The best way is try it yourself. Everyone is invited to a free evaluation by going to our BOM Portal webpage and the free three hour is on top of this page. You just put your email and get evaluation. We also have a BOM Portal webinar on January 24th in Europe and on January 25th in the United States where we will talk in greater detail about BOM Portal and give you a demonstration of the use cases we discussed today. So, welcome to our webinar.

Zach: Yeah. And anyone who's interested, make sure to take a look at the show notes and you'll see some links where you can learn more about the BOM Portal and access some great resources. Thank you both so much for being here today and discussing this. In my opinion, this is a really exciting feature and I think it's gonna be a great productivity booster for engineering teams. To everyone that's out there listening, we've been talking with Damir Khayrutdinov, Product Manager at Altium, and Ananth Avva, General Manager of Altium's cloud business. Make sure to check out the show notes. You'll find some links to some great resources where you can learn more about the BOM Portal. If you're watching on YouTube, make sure to hit the subscribe button and hit the like button. You'll be able to keep up with all of our podcast episodes and tutorials as they come out. And last but not least, don't stop learning, stay on track, and we'll see you next time. Thanks, everybody.