What is Product Lifecycle Management?

All products follow, at an abstract level, the same basic lifecycle. First, they start with a spark of an idea that is transformed into a set of product requirements. Next, these requirements drive the design process. The finalized design is then realized into a tangible product that is then deployed into the marketplace. Typically products evolve over time in the market to match changes to consumer trends, competitive pressures, or regulatory requirements. But, of course, not all ideas make it to market, so this lifecycle can often be cut short or undergo several iterations of interim stages before proceeding.

Confusingly, the term product lifecycle can often be used in the marketing world to cover the period that the product is on sale. This subordinate lifecycle covers the introduction of the product to the market and sales growth until it reaches maturity and market saturation. The end of the marketing life is indicated by a decline in sales before it is retired, replaced, or reworked. This represents a subset of the overall lifecycle of the product.

This article looks at the overall product lifecycle from forming an idea through design, development, deployment, and ultimately retirement. In PCB design and hardware design in general, teams have to be cross-functional as they create new products, so there are multiple elements in a new product that can limit its lifecycle (individual chips, materials, enclosure elements, other components, and embedded software/firmware).

Overview of Product Lifecycle Management

Product lifecycle management (PLM) is simply the process of managing the product life cycle stages efficiently and effectively to ensure business goals are achieved. The achievement of these aims comes by managing business processes and data across a product's lifecycle, supply chain, and delivery to the end user/customer. PLM covers all the steps a product takes over its lifetime, from its initial design and development, through manufacturing, to its marketing and in-service support, and then finally, a product's disposal and end-of-life.

From the perspective of designing physical products, whether they are electronics or not, PLM must draw together all parties involved in a product's production to streamline design and production processes. The goal of PLM is to produce the right product with high yield, bring it to market at the right time, and maximize profits by generating consumer demand and outperforming competitors.

To be truly effective, PLM processes must integrate with other cornerstones of a comprehensive business management system:

- Enterprise resource planning (ERP)

- Supply chain management (SCM)

- Customer relationship management (CRM)

- Supplier relationship management (SRM)

The above sub-systems in a PLM system typically only focus on the physical product, ability to produce it, and the ability to deliver it to customers. Newer cloud collaboration platforms in the electronics space allow design data to be housed and managed alongside all other data used in PLM to ensure there is a single source of truth for all aspects of a product.

Product Lifecycle Management: Conception

The conception phase is the stage where an initial idea is converted into a viable concept for a product. This is a product that is feasible to create, has a market with sufficient demand to meet sales targets, and would deliver an adequate return on investment over its life to be an attractive proposition.

Feasibility will come down to whether the technology exists to realize the idea and if the business has the resources to design and develop that idea into a product. Front-end engineering can begin in this phase as part of a feasibility assessment, where requirements are evaluated and adjusted while being compared to the required functionality and user experience. Critical components that are the main enablers of product functionality may also be selected in this phase.

The marketability will come down to whether sufficient customers are willing to purchase the product at the target price. This will be influenced by the demographics of the target audience, existing competition, and the effects of rival products also under development.

The return on investment assessment balances predicted sales income against development, operating, and support costs over the product's lifetime.

The conception phase aims to create a set of product requirements that precisely define what the product should do and not do. The PLM processes should support the collation and management of these product requirements into a single source of truth from which the product design is produced.

Product Lifecycle Management: Design

The design phase transforms the product requirements into a blueprint for a developed product, including any prototyping and proof of concept activities to evaluate a product against its design requirements. Typically, the design phase is an iterative process, using feedback from each loop to refine and enhance the design until it meets requirements to the satisfaction of stakeholders. In the electronics industry, computer-aided design tools, and simulation support design processes.

Today, cloud collaboration tools are becoming the norm for PCB design teams as these platforms help integrate PLM across different design disciplines. This includes design and production data across the following areas:

- Electrical design data, including schematics and PCB layout

- Mechanical enclosure designs and models created in MCAD software

- Simulation data at the circuit level and PCB layout level

- Fabrication and assembly files, including a complete bill of materials

- Documentation data and other reports generated during design reviews

- Embedded firmware code and binaries used to flash firmware during production

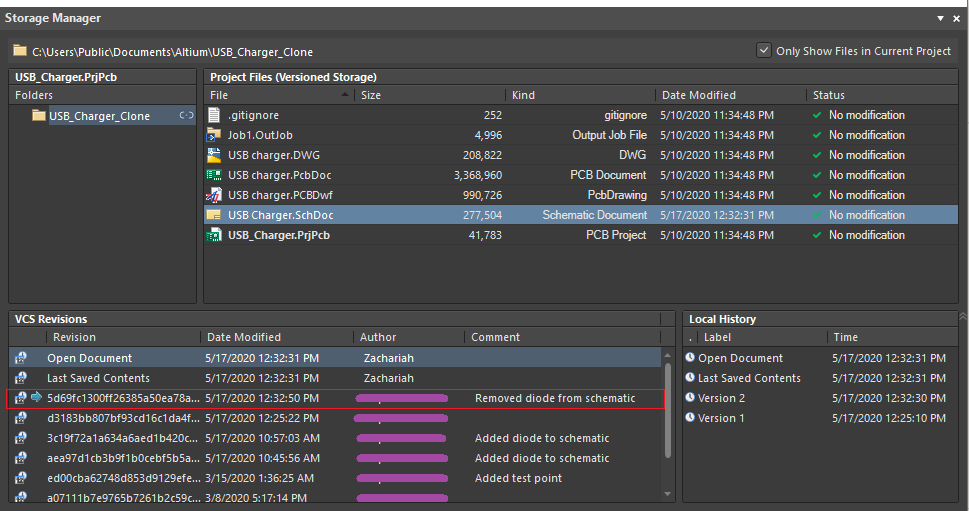

The PLM processes should support creating, sharing, and managing the design data generated in the design phase. Modern PLM systems and processes can help centralize this data and track design progress using an integrated version control system, which design team members can use to manage changes to the product during design and in successive iterations throughout a product's lifecycle. The PLM system should support the collation and management of these product design data into a single source of truth from which the product can be manufactured.

Product Lifecycle Management: Realization

The product realization phase encompasses transforming the completed design into a production-ready product that can be manufactured at scale with high yield. The release of the finalized product to the market follows, where development processes end and the marketing & sales processes take over for product launch, distribution, and promotion. The PLM processes should support the collation and management of the product information into a single source of truth from which the product documentation, such as user manuals or marketing materials, is produced. A central source of design, production, and documentation data helps ensure the production team will be working from the most recent data and can produce with highest yield and repeatability.

Production data should be kept in the PLM system and stored in version control alongside design data. The two should not be kept separate as they are intimately related, and it is often the case that designers need to examine production data alongside the standard set of design data.

Product Lifecycle Management: Deployment

The product deployment phase covers the in-service stage of a product's lifecycle, encompassing support activities and customer feedback to manage reliability and serviceability issues. Continuous improvement processes take this feedback and usability metrics into product refinement and improvement activities, supporting the development of upgrades and alternated configurations within a product family. The PLM processes should support the collation and management of the product usage, fault reporting, and in-service support information into a single source of truth that can be fed back into the development processes.

End-of-Life

At the conclusion of the product life cycle, management of the withdrawal of the product from the market through its retirement and disposal will be necessary. Products may typically be replaced with a new variant that provides additional features and capabilities, although the previous variant of a product may exist in the supply chain and in the field for some time. The PLM processes should support the management of the product information to support disposal processes.

Implementing a PLM System

PLM systems streamline project management for electronic design projects by integrating processes and data into a cohesive solution that all stakeholders, from project managers to designers, marketers to support staff, can access and utilize. From a design team point of view, it allows team members access to all relevant information beyond the typical subset available in siloed organizations. This greater visibility can help prevent issues due to issues with the clarity of requirements or ambiguities. It also gives other stakeholders visibility of design decisions and ensures that their viewpoints are taken into consideration.

Properly implemented, PLM will support data management across the product development activities to enforce the single source of truth concept. In addition, it will maintain the integrity of the data and support its administration. A correctly implemented PLM system will improve project delivery by efficiently managing workflows that optimize processes and reduce development times to achieve a faster time to market. This timeline improvement can be crucial in a competitive marketplace where the first to market can gain sales momentum and reputational benefits over later arriving products.

The PLM system will introduce automation and verification into processes that help reduce errors across the lifecycle, reducing the effort required to resolve issues and resource wastage when problems are not found until the realization phase. These benefits are mainly accomplished with the integration of design and production processes.

The PLM system will improve inter-stakeholder communications and project data visibility to deliver better quality development and reduce the risk of engineering errors through misunderstanding or missing information. This benefit is particularly significant with geographically dispersed, multi-disciplinary teams collaborating on a product development project.

Conclusion

Formal product lifecycle management can deliver significant improvements across the development phases of a project. Benefits are restricted to project management and all stakeholders, including the product design team. The core of product lifecycle management is around project data management. With the adoption of Industry 4.0 and the introduction of artificial intelligence solutions to enhance development processes, product lifecycle management systems can be seen as a necessary next step for electronic device development organizations.

Altium Designer is the only PCB design platform that provides a complete set of data management features alongside the industry’s best design tools and a cloud-driven integrated version control system. Design teams can use the complete set of design features in Altium Designer with the Altium 365 platform to integrate with industry-standard product lifecycle management platforms and track designs from concept to production.

Still wondering what is product lifecycle management? We have only scratched the surface of what is possible to do with Altium Designer on Altium 365. Start your free trial of Altium Designer + Altium 365 today.

Back

Back