BOM Portal Introductory Tutorial

Why Early BOM Visibility Matters for Procurement:

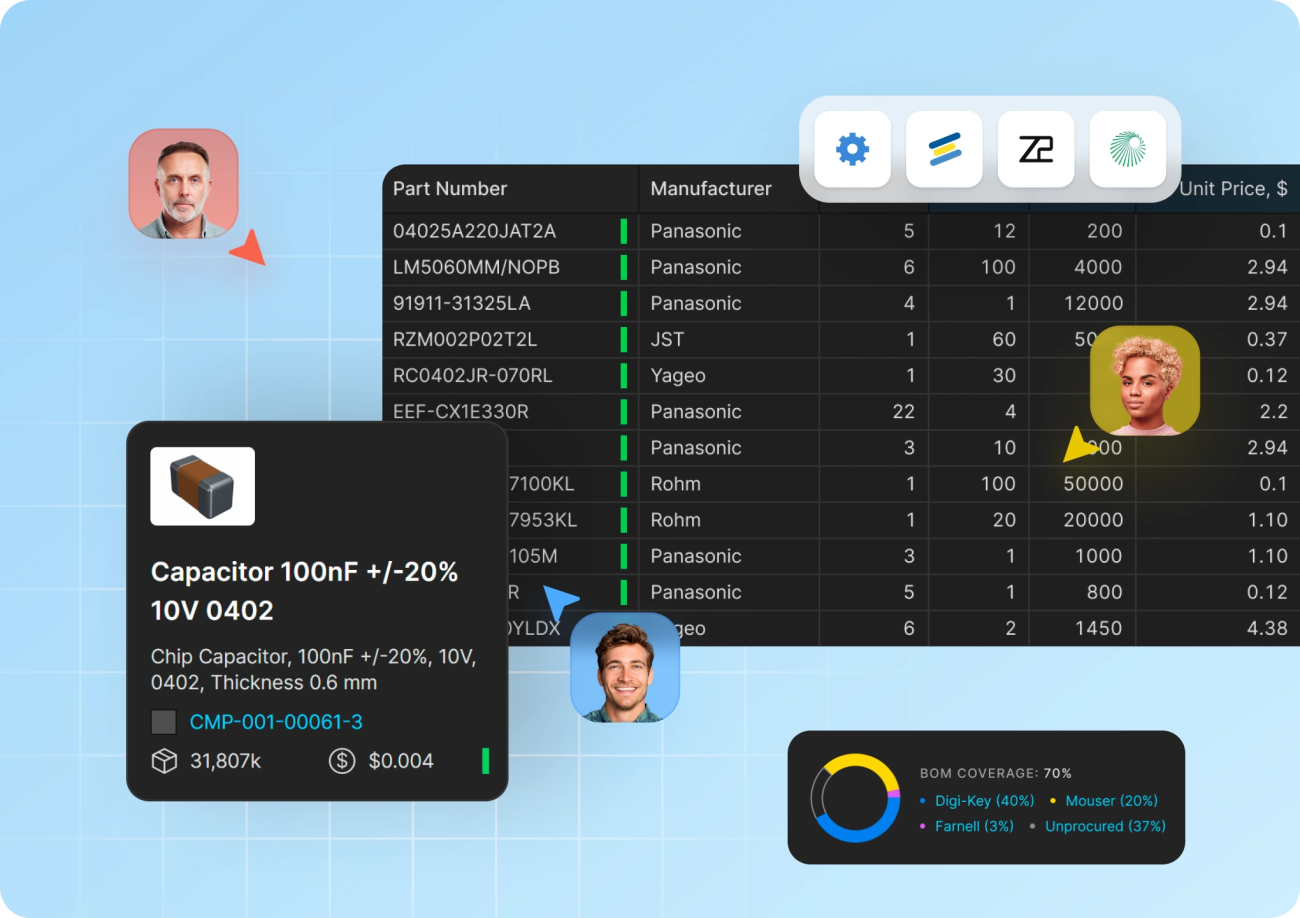

Most procurement teams discover supply chain issues only after engineering finalizes designs—when components are already obsolete, unavailable, or exceed budget. Late visibility forces reactive firefighting: scrambling for alternatives, negotiating emergency pricing, and delaying production. BOM Portal eliminates that friction by giving procurement live access to BOMs during the design phase, with automatic enrichment from trusted data sources like Octopart, IHS Markit, SiliconExpert, and Z2Data.

These guided demos show how to shift left—catching and solving supply chain risks when they're easier and cheaper to fix.

Early BOM Visibility with Data Enhancement:

Engineering finalizes designs and tosses BOMs over the wall to procurement, often with components already obsolete or unavailable. By the time procurement sees the BOM, design changes are expensive and time-consuming.

In this walkthrough, you'll learn how to:

- Create a managed BOM from a PCB project for early visibility

- View auto-enriched data (availability, pricing, lifecycle, compliance)

- Comment on BOM lines and assign tasks to engineering

- Track changes with version-controlled updates

With shift-left visibility, you identify supply chain risks while design changes are still cheap. Instead of discovering obsolete parts at production planning, you collaborate with engineering early—when swapping a component takes minutes, not weeks.

BOM Analysis & Risk Assessment:

Supply chain risks discovered too late in the development cycle cause expensive redesigns, production delays, and last-minute component substitutions that compromise product quality.

In this walkthrough, you'll learn how to:

- Review the Dashboard for BOM health metrics and risk indicators

- Identify obsolete parts (NRND, EOL), compliance violations, and stock issues

- Filter Issues tab by category to prioritize resolution

- Use where-used analysis to see project impact

- Verify data confidence from multiple provider sources

Real-time risk assessment replaces reactive firefighting with proactive risk management. You see the full picture—obsolescence, compliance, and availability—before committing to production quantities, protecting both schedule and budget.

Alternate Management:

Emergency sourcing of alternatives disrupts production schedules. When a component goes obsolete or out of stock, procurement scrambles to find substitutes without clear guidance on electrical equivalence or engineering approval.

In this walkthrough, you'll learn how to:

- Find alternates using intelligent suggestions or parametric search

- Review confidence scores to identify drop-in replacements

- Auto-fill alternates or add them manually per BOM line

- Document selection rationale with comments for engineering

With alternate management, you shift from reactive scrambling to strategic planning. You qualify backups during design—not during a stock-out crisis—giving you negotiating leverage and eliminating single-source risk.

Supplier Strategy & Cost Optimization:

Budget overruns and missed cost targets occur when procurement gains visibility too late. Without early access to BOM data, there's no opportunity to negotiate design-for-cost decisions or leverage preferred supplier relationships.

In this walkthrough, you'll learn how to:

- Compare pricing and availability across distributors in the Supply Chain Tab

- Set favorite suppliers to prioritize strategic relationships

- Analyze quantity breaks and MOQs for optimal order sizing

- Select Order List Presets to minimize order complexity

- Set target prices and track variances to budget goals

Cross-supplier cost analysis turns BOM management into strategic sourcing. You identify cost reduction opportunities before production commits, negotiate better pricing with visibility into volume needs, and align engineering on cost constraints early enough to matter.

Multi-BOM Consolidation:

Siloed project management causes missed volume pricing opportunities. When each project procures independently, teams pay higher unit costs and carry excess inventory—despite using many of the same components across products.

In this walkthrough, you'll learn how to:

- Create Consolidated BOMs from multiple projects

- View aggregated quantities for volume pricing opportunities

- Identify common parts across product lines for standardization

- Generate consolidated order lists for portfolio-wide procurement

BOM consolidation transforms fragmented purchasing into strategic sourcing. You unlock volume discounts, reduce supplier complexity, and make data-driven standardization decisions that lower cost and risk across your entire product portfolio.

Lifecycle Monitoring & Continuous Supply Chain Intelligence:

Reactive firefighting when supply disruptions occur leaves procurement discovering stock-outs, price increases, and lifecycle changes only when placing orders—forcing last-minute substitutions and production delays.

In this walkthrough, you'll learn how to:

- Track parts across your workspace with Parts in Use

- Filter by lifecycle, compliance, or manufacturer to manage risk

- Monitor availability and receive alerts for supply changes

- Sync with design tools for real-time change visibility

Continuous monitoring shifts you from reactive to predictive. You catch supply disruptions early, maintain alternate qualification ahead of need, and keep stakeholders informed on readiness—eliminating surprises and protecting production schedules.

What's Next?

You now have the foundation for proactive BOM management with integrated supply chain intelligence. Here's how to expand your capabilities:

Advanced BOM Portal Features:

BOM CoDesign enables bi-directional workflow between Altium Designer and BOM Portal. Engineers see procurement recommendations directly in the ActiveBOM panel, while procurement updates managed BOMs after design changes. Both teams stay synchronized automatically without manual handoffs.

Library Management links BOMs to your component library for pre-approved parts and Internal Part Number (IPN) support. Automatic Part Choices align engineering and procurement on standardized components, reducing proliferation and speeding up BOM creation with approved alternatives.

BOM Releases & Lifecycle Management creates formal releases with lifecycle states—Draft, Prototype, Production, or Abandoned—ensuring teams work with approved versions. Track revisions, compare changes between releases, and export released BOMs to CSV/Excel or publish directly to PLM systems.

Advanced Data Extensions provide deeper obsolescence intelligence and alternative recommendations. Add SiliconExpert for YTEOL (Years To End Of Life) forecasting and Product Change Notices, or enable Z2Data for composite risk scoring (0-100) and multi-factor compliance analysis.

Documentation:

For detailed feature documentation:

- BOM Portal Overview and Main Workflows

- Sourced Manufacturer and Supplier Data

- Data Integrations:

- Essential Part Intelligence (Octopart, IHS Markit)

- SiliconExpert Extension

- Z2Data Extension

- BOM Error Detection and Correction

- Consolidated BOM Management

BOM Portal delivers measurable value for procurement teams. You reduce risk by catching obsolescence early, save time by eliminating manual data hunting across supplier sites, and optimize costs through volume consolidation and strategic supplier relationships. Most importantly, you gain cross-team collaboration that aligns engineering and procurement on component decisions from day one—not after designs are finalized.