Getting Started for Manufacturing Engineers

01- Viewing Manufacturing Packages:

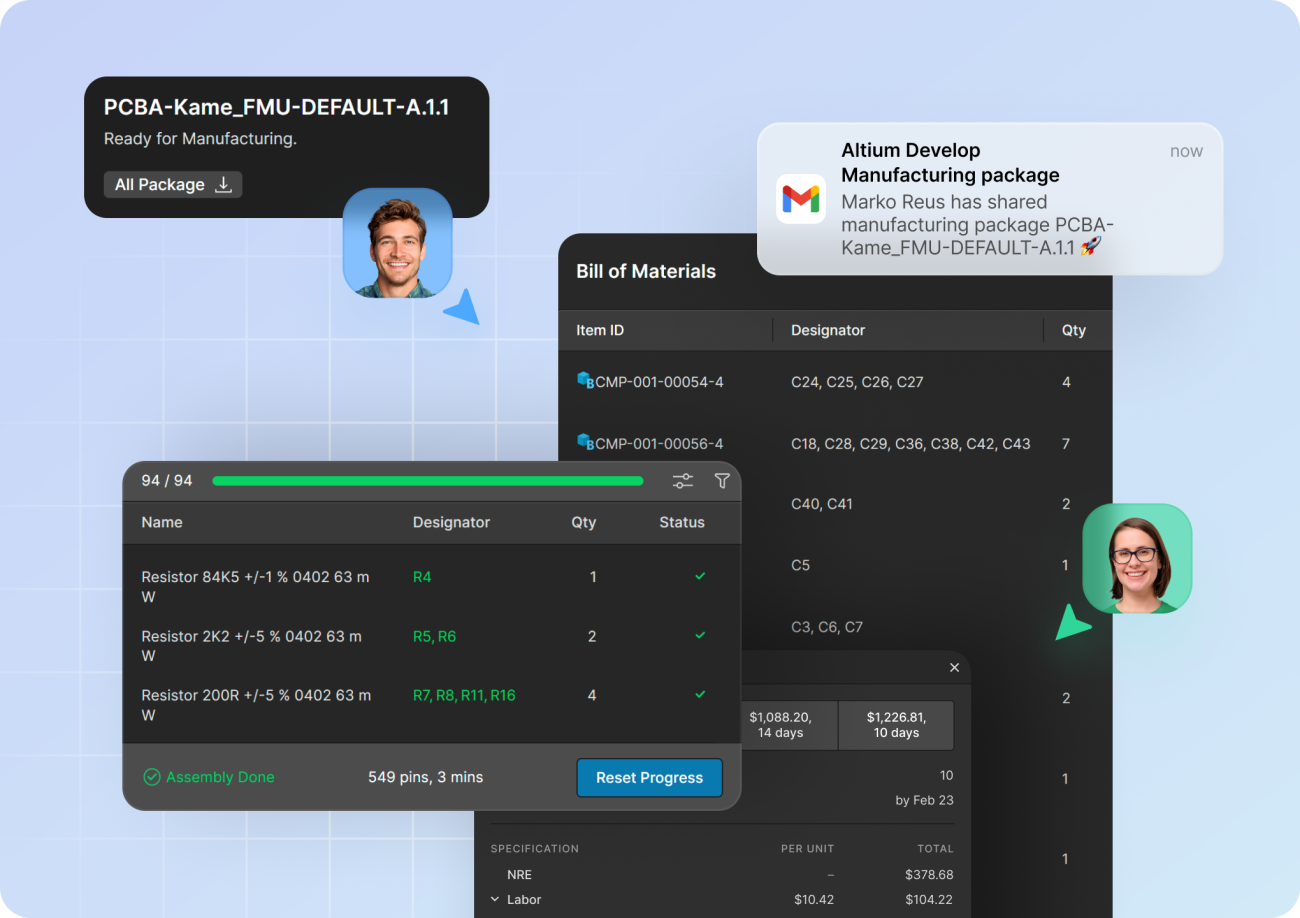

When manufacturing data is locked behind complex CAD tools or scattered across disparate ZIP files, engineers often waste time chasing the right version or manually verifying specifications. This guided demo shows how to access a unified, browser-based Manufacturing Package that centralizes all fabrication and assembly data without requiring a specialized CAD license.

In this walkthrough, you will learn how to:

- Securely access production-ready data via automated email invitations.

- Inspect high-fidelity fabrication data, including Gerbers, layer stackups, and drill tables, directly in your browser.

- Verify component placement and mechanical fit using interactive 2D/3D assembly views and measurement tools.

- Audit the Bill of Materials (BOM) and individual file structures to ensure data integrity before the production run.

- Extract specific data sets or the entire release package as a structured ZIP file for factory-floor execution.

By following these steps, you will see how the Manufacturing Package Viewer streamlines the handoff from design to production, reducing the risk of fabrication errors and ensuring every stakeholder has the right data at the right time.

02 - Paperless Assembly Guidance:

Manual PCB assembly is often a slow, error-prone process involving static paper drawings and cumbersome BOM cross-referencing. The Assembly Assistant replaces these outdated methods with a dynamic, digital environment designed specifically for the assembly bench. This guided demo shows how to navigate this interactive interface to speed up component placement and eliminate guesswork.

In this walkthrough, you will learn how to:

- Launch the digital interface to replace traditional paper assembly guides with a high-fidelity, interactive tool.

- Customize your workspace by adjusting display settings and component data fields to match your specific workflow.

- Locate parts instantly using powerful search filters to find specific components on even the densest boards.

- Execute a guided assembly flow with intelligent zooming and highlighting that directs you to the exact placement for every part.

- Navigate complex boards with seamless flipping between Top and Bottom layers to ensure accuracy across the entire assembly.

By following these steps, you will see how the Assembly Assistant provides a foolproof roadmap for the manual assembly process, reducing operator fatigue and significantly lowering the risk of misplaced or misoriented components.

03 - Predict Supply Chain Risk & Deliver on Time:

Reactive firefighting when supply disruptions occur leaves procurement discovering stock-outs, price increases, and lifecycle changes only when placing orders—forcing last-minute substitutions and production delays.

In this walkthrough, you will learn how to:

- Track parts across your workspace with Parts in Use.

- Filter by lifecycle, compliance, or manufacturer to manage risk.

- Monitor availability and receive alerts for supply changes.

- Sync with design tools for real-time change visibility.

Continuous monitoring shifts you from reactive to predictive. You catch supply disruptions early, maintain alternate qualification ahead of need, and keep stakeholders informed on readiness—eliminating surprises and protecting production schedules.

04 - Align Engineering Data with Cloud PLM:

Manual data entry between your design environment and your PLM is a major bottleneck that leads to outdated part data and costly production delays. The Duro PLM Connector automates this bridge, ensuring that component parameters, lifecycle states, and release packages flow seamlessly into the Duro ecosystem. This guided demo shows how to configure the connection to ensure manufacturing always has access to the single source of truth.

In this walkthrough, you will learn how to:

- Establish a secure link between your Altium Agile Workspace and the Duro PLM platform.

- Map parametric data to ensure component attributes in Altium 365 align perfectly with your Duro database schema.

- Define synchronization logic to control how component types are updated and which parameters take precedence during a sync.

- Automate project publishing to distribute Design, Assembly, and Fabrication data sets to Duro automatically upon release.

- Schedule sync intervals to eliminate manual uploads and ensure your enterprise data is always current.

By following these steps, you will see how the Duro PLM eliminates manual data silos, providing full product lifecycle traceability and ensuring manufacturing always works with verified, production-ready parts.

05 - Manufacturing Services from Trusted Altium Partners:

The transition from a finished design to a physical board is often a fragmented process of exporting files, manual quoting, and back-and-forth emails with vendors. Altimade—the Altium-to-manufacturing service—brings the factory floor directly into your design environment. This guided demo shows how to use the Manufacturing panel to get real-time pricing, verify production readiness, and place an order without ever leaving your project context.

In this walkthrough, you will learn how to:

- Access professional manufacturing services directly within Altium Designer via the integrated Manufacturing panel.

- Configure fabrication preferences such as board quantity, solder mask, and silkscreen colors with instant feedback.

- Identify production "showstoppers" through automated BOM and manufacturing constraint checks before you spend a dime.

- Analyze transparent cost breakdowns to understand how lead times, materials, and components impact your total project spend.

- Execute a seamless checkout that bridges the gap between the desktop design environment and the Altium 365 order management portal.

By following these steps, you will see how Altimade simplifies the procurement process, allowing you to move from a completed PCB document to a submitted order in minutes.

Note: Altimade is currently in Beta. As we continue to refine the integration between design and manufacturing, we appreciate your feedback on the flow and functionality.