Healthcare Is Facing a Digital Imperative. Is Your ECAD in Alignment?

Digital transformation in the healthcare industry might be better labeled as a digital imperative. Recent events and key technological advancements are forcing an industry-wide evolution that is accelerating and bringing several healthcare trends to innovation.

For those in the know, every aspect of the healthcare industry is quickly adapting to changes in consumer preferences and rapidly moving to incorporate recent digital innovations from adjacent fields. Telemedicine, artificial intelligence-enabled electromedical devices, machine learning, and cyber-secure health records are revolutionizing the industry's ability to diagnose, treat, and deliver healthcare. The effect is a fundamental reshaping of how physicians and providers make decisions and interact with patients.

This evolution is evident in a recent Accenture Digital Health Technology Vision 2021 report, which surveyed 399 healthcare executives across six countries. In the report, 81% of healthcare executives said, "the pace of digital transformation for their organization is accelerating," and 93% reported, "they are innovating with a sense of urgency and call to action." Also, 66% of the healthcare executives surveyed said "they will be in the cloud within the next year," and 96% "within three years.” The report also states that "the industry has accepted that digital is here to stay,” with 87% of executives saying their organization's business and digital technology strategies are becoming inseparable.

Evolving Industry

As the industry evolves, companies strive to not only innovate but also to push the boundaries of what is possible to enhance and streamline physicians' work, optimize doctor-patient interactions, improve patient outcomes, and reduce human error.

For industry veterans and newcomers alike, innovating beyond boundaries provides an unprecedented ability to solve problems and take advantage of new opportunities for growth like never before. They are both responding to unprecedented recent events and technological advancements, including:

- Acceleration of changing consumer preferences for, and comfort with, telehealth and other consumer-level digital health monitoring and reporting devices

- Pressure from patients and regulators to improve quality, safety, and access to healthcare and to reduce overall costs

- Maturation of artificial intelligence (AI) and Machine Learning (ML) technologies to diagnose and plan treatment

- Disruption from care delivery retailers and startups

- The proliferation of digital health products and services from traditionally non-medical high-tech and consumer technology companies

Companies are delivering innovative products such as telehealth and medical IoT devices incorporating health monitoring apps and diagnostic software incorporating artificial intelligence and machine learning. Additionally, the increasing availability of digital technologies and consumer-grade medical electronic devices offer quick and enhanced patient care diagnostic and therapeutic services, making them increasingly popular among general consumers. Moreover, the rising demand for minimally-invasive surgeries and non-invasive diagnostic devices all combine to drive the demand for innovative medical electronics across the globe.

This demand comes with significant growth opportunities. According to Precedence Research, “the global medical electronics market size is expected to be worth around US$ 248.4 billion by 2030 from US$ 81.6 billion in 2020, growing at a CAGR of 11.8% from 2021 to 2030.”

But innovations and opportunities in the healthcare industry always require something extra. Healthcare companies and electromedical devices face some of the most rigorous internal and external oversight. Companies must adhere to strict government regulatory requirements and quality and safety regulations for the products they develop and their business and engineering processes.

Evolving Engineering

Modern medical technologies and electromedical products are rapidly advancing the realm of what's possible to save lives. And while these products have the potential to provide care like never before, engineering and designing electromedical devices requires addressing unique challenges to deliver not only innovative products but products for which safety and regulatory compliance are paramount.

Due to strict government regulatory requirements, all electromedical devices must maintain compliance that includes enhanced levels of quality and safety. As a result, product development processes require a repeatable, compliant, and auditable approach. This approach must span the development process from conception and requirements to release and manufacture. It must also be applicable across all the design domains and provide lifecycle, risk management, and verification and validation capabilities. Additionally, the development processes must consider the product as a whole and all the individual components associated with the product's complexity and service life.

Business and engineering management systems and lifecycle design processes provide accurate, meticulous control over requirements and procedures for managing a product's electronic design and parts data from conception to the final shipment of products. However, many medical device companies rely on existing processes and design/data management tools that lack the capability to manage the full product definition, design, and output/documentation. These processes and tools are outdated or overly manual, making it challenging to implement repeatable processes and comply with regulatory requirements.

These manual processes and ad-hoc management systems suffer from:

- Disparate silos of product and quality information and records

- Disconnected quality, engineering, operations, and partners

- Issues creating design controls and workflows to comply with regulatory requirements

- Problems creating and tracking product requirements through design concept to output

- Poor visibility of data when choosing safe, compliant components with high reliability and extended life cycles

- Quality and product issues stemming from poor processes

To address these challenges, companies are increasingly looking to digitally integrate disparate engineering, regulatory, and manufacturing processes and data into a consolidated PLM environment. As product lifecycles and supply chains become increasingly digitized, PLM systems play an ever-more critical role in managing design and component data throughout the product's development. As a result, PLM is a key infrastructure component for ensuring a successful digital transformation of the end-to-end product development lifecycle.

Evolving ECAD

Successful healthcare and electromedical device companies who have begun their digital transformation journey know that effective adoption of information technologies and digital platforms such as ERP, MRP, and PLM systems across their business and enterprise organizations can streamline operations that improve performance and gain them a competitive edge.

But in established and startup companies, it's too common for the process of electronics development to be siloed and only loosely linked. The electronics design for electromedical devices is still largely disconnected and digitally isolated from the rest of the business and enterprise.

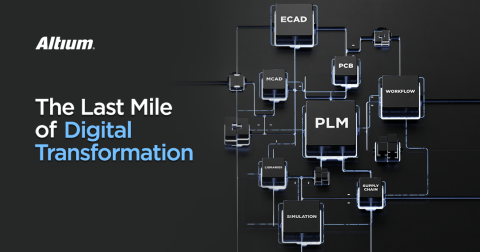

PLM integration for ECAD is an essential component to cross the "Last Mile" of the digital transformation journey. Product-centric lifecycle and quality management systems help connect design, quality, and product development processes. They can represent a single source of truth to help comply with regulatory compliance needs and streamline product development.

- Unify quality and product record management

- Improve process control and traceability

- Address quality issues earlier with design data and BOM visibility

- Assure compliance with regulations and requirements

- Establish and maintain strong design controls and workflow to simplify development and compliance

- Identify, analyze, and resolve issues managed processes

A digitally-transformed ECAD ties together all the elements of electronics development and its data. It acts as a hub for the entire PCB design process and integration across the enterprise, including configurable process workflows, team assignments, component, and design lifecycle management, version/revision control, ECAD-MCAD collaboration, and design reviews.

Altium Enterprise Solutions: This Last Mile of Digital Transformation

The Altium enterprise solutions provide comprehensive, digitally-integrated, electronics and PCB design capabilities. They enable enterprise organizations of all sizes to leverage their best-in-class technologies, development processes, and people allowing them to fundamentally transform their electronics design environment.

By digitally-connecting electronics design to existing technology investments – including PLM, MCAD, and simulation – the Altium enterprise solutions allow companies to seamlessly integrate their product development teams and processes from concept to realization. In addition, digitally-managed process workflows, along with connected resources, enable intuitive and valuable collaboration across domains and disciplines.

- Digitally Connect ECAD to the Enterprise

Integrating schematic and PCB layout into a digitally-connected, managed, electronic product development environment enables seamless integration with existing technology and design investments across the enterprise. Once ECAD becomes part of the enterprise digital workflow, all team members gain on-demand access and visibility to design information in both the earliest stages of development – when potential problems are easier to address – and throughout the entire product design process. Learn more about digitally-integrating Schematic Design and PCB Layout

- Cross-domain and Cross-discipline Collaboration

Digitally-connected electrical engineers and PCB designers can easily collaborate in a managed way with adjacent domains – including mechanical, procurement, and manufacturing – decreasing miscommunication and common errors associated with manual processes that affect siloed teams today. Designers and stakeholders – including product management, supply chain vendors, and manufacturers – also gain transparency to electronic design work in progress as well as easy access to real-time component and supply chain data. People in each domain can continue to work in the way they typically work without having to become experts in another domain or disrupting other people’s workflows. Learn more about truly digitally-integrated ECAD-MCAD collaboration

- Digitally-Managed Workflows, Process, and Resources

Workflow automation is essential for any enterprise organization looking to streamline their processes and improve efficiency. By digitizing and capturing best practices and regulatory requirements in automated workflows, organizations can develop repeatable, predictable processes and significantly reduce human error. Automated workflow management also provides a complete history, along with automated task management and automated notifications, making it easy to track project progress on demand without the need for manual status updates. Learn more about workflow management

The digital continuity that the Altium enterprise solutions provide enables project challenges to be addressed and decisions to be made at the critical points of impact – when they matter most.

The Altium enterprise solutions are the most lightweight, easy-to-implement electronics design solutions for enterprise organizations of all sizes or maturity, making the last mile of digital transformation not only possible – but easy.

Is Your ECAD in Alignment?

Companies designing electromedical devices face increasing customer-centric demands for more comfortable, wearable, and implantable devices. Medical devices must be smaller, more intelligent, and more connected than ever while meeting regulatory standards and getting to market quickly. But ensuring quality and regulatory compliance while also delivering innovative, best-in-class medical devices has never been more critical and challenging. You require the most effective design solution and efficient processes to compete in this highly complex and demanding industry.

True digital transformation means letting go of outdated business and enterprise processes and trusting that disruption will yield significant results. It also means meeting healthcare's digital imperative and keeping pace with innovation. Your electronic engineering design department cannot be left behind and must fundamentally transform at every level.

Altium has you covered with the Altium enterprise solutions. Built on the same powerful, customer-centric PCB design foundation of Altium Designer® – the world’s most popular PCB design software – Altium is transforming electronics design.