How Integrated PCB Design Cuts Development Time for Complex Electronics

Modern electronics are astonishingly complex, but the software tools many teams use to design them haven't kept up. Engineers are still forced to wrestle with a disjointed workflow, a disconnected mess of separate apps. This stop-and-start process is no longer just an annoyance but a critical bottleneck. Every manual file export, every data-sync error, and every time an engineer switches applications is a tax on the project schedule, introducing delays and costly respins. The antidote is a move to a truly integrated design environment.

Key Takeaways

- The primary way disconnected tools slow teams down is context-switching, the mental and technical overhead of stopping work in one app, translating data, and opening another.

- A truly integrated platform connects schematics, 2D/3D PCB layout, simulation, and data management to a single, underlying data model, eliminating data translation errors.

- Integration allows teams to pull supply chain analysis and simulation left (earlier in the process) to prevent massive delays from part shortages or late-stage design failures.

- Altium Agile Teams extends this integration beyond the ECAD tool, connecting design data to enterprise systems (PLM, ERP) to deliver both technical (fewer errors) and operational (faster processes) efficiency.

The Context-Switching Tax: Why Disconnected Tools Are a Bottleneck

Disconnected tools kill productivity by forcing context-switching, the mental and technical overhead of stopping work in one application, exporting data (often in a lossy format like IDF or DXF), opening another application, importing that data, and then trying to re-establish focus.

In a typical fragmented workflow, an engineer might:

- Finish a schematic in one tool.

- Export a netlist.

- Open a separate layout tool and import the netlist.

- Do the layout, then export a 3D model (like a STEP file).

- Send that file to a mechanical engineer, who imports it into their MCAD tool to check for fit.

- If there's an interference, the entire process repeats.

Each step is a potential point of failure and a guaranteed time-sink. This context-switching tax is the single biggest drain on development time for complex products. In fact, analysis of disconnected workflows shows that engineers can spend up to 30% of their time just looking for the right design information, often finding and using the wrong version.

What Is an Integrated PCB Design Environment?

An integrated PCB design environment is one where schematic capture, simulation, 2D/3D PCB layout, and data management all talk to each other in real-time. Crucially, this is achieved by operating from a single, underlying data model.

This means the schematic and the PCB are not separate files that need to be synced. They are just two different views of the same design data. When you change a component in the schematic, it changes in the layout instantly because there is no data to translate. This single source of truth is the foundation for cutting development time.

Three Ways Integration Gets You to Market Faster

Moving to an integrated platform is a direct strategy for accelerating the development cycle.

1. It Kills the Context-Switching Tax

In an integrated tool like Altium Agile Teams, the schematic, 3D PCB, and component library are all part of one environment. There is no export/import between these core functions. Engineers can stay in the zone, switching from a 2D layout view to a 3D clearance check with a single keystroke, allowing them to focus on solving difficult design problems, like high-speed routing or fitting components in a tight enclosure, not on managing file formats.

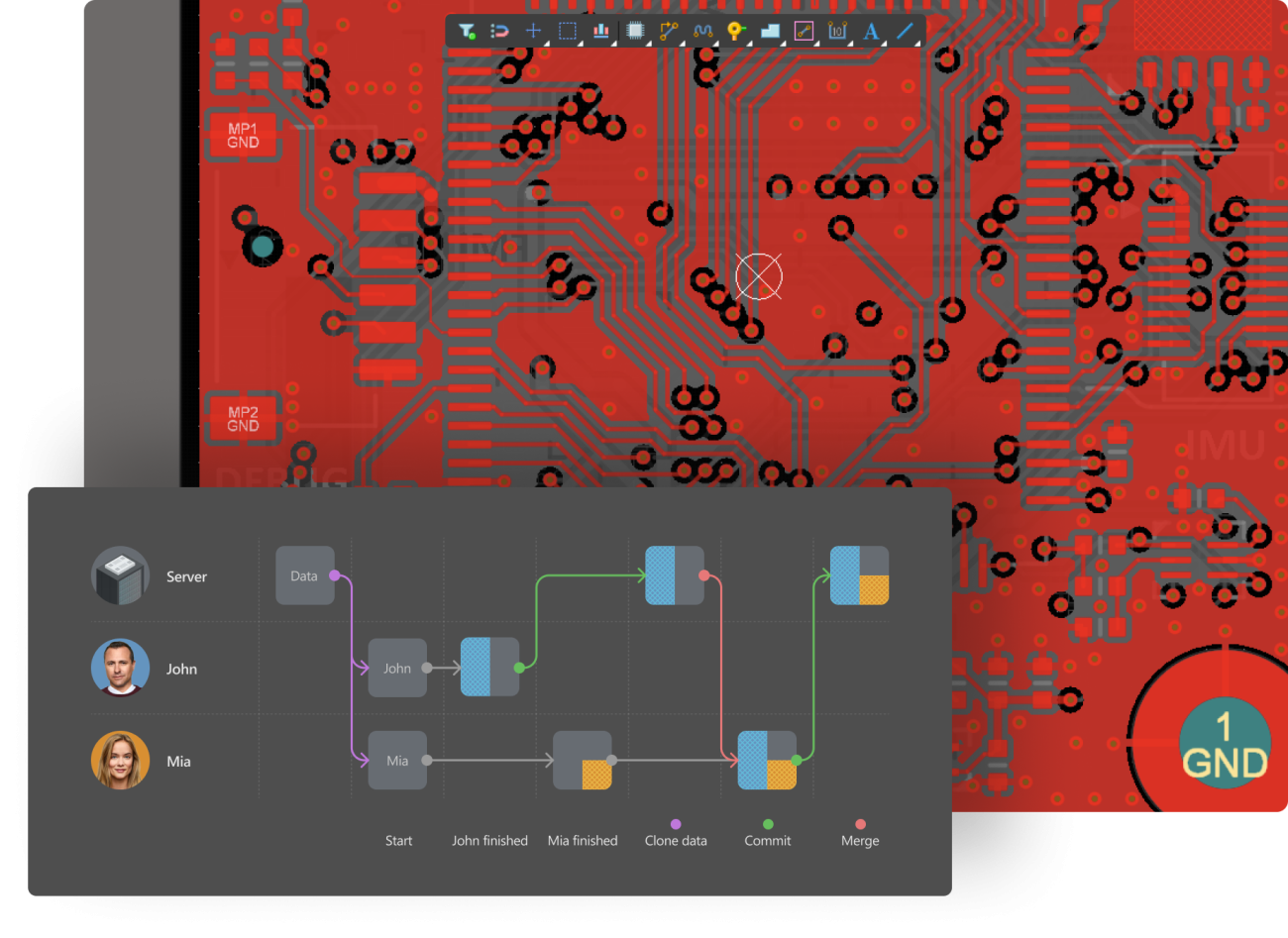

2. It Enables True, Real-Time Collaboration

The old model of collaboration is emailing “design_v5_final_ACTUAL.zip” and hoping nobody overwrites your work. This creates version-control nightmares and brings concurrent design to a halt.

Modern unified platforms for advanced multidisciplinary collaboration, like Altium Agile Teams, are cloud-native, which allows for:

- ECAD/MCAD Co-design: Mechanical engineers can see the live PCB assembly inside their native MCAD tool and push enclosure changes directly to the PCB editor.

- Web-Based Reviews: Managers, component engineers, and even clients can review and comment on a design from any web browser, without needing a full ECAD license.

- Concurrent Design: Multiple PCB designers can work on the same board layout simultaneously, dramatically cutting down layout time for large, complex boards.

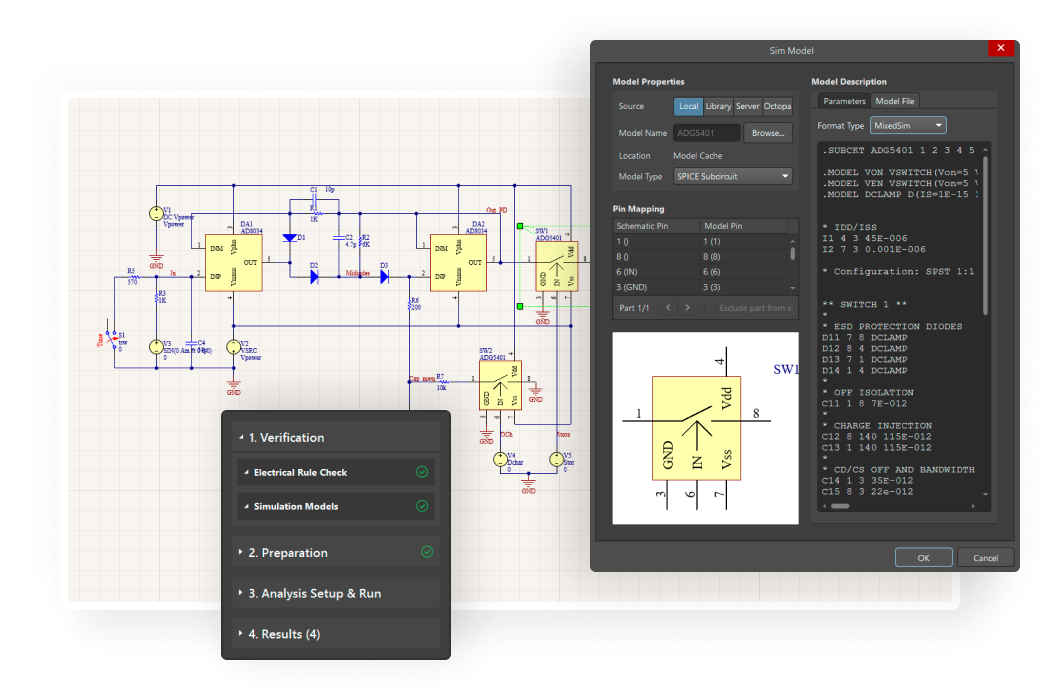

3. It Pulls Supply Chain and Simulation "Left"

In a disconnected flow, simulation and BOM checks are downstream tasks. They happen after the layout is considered done. This is incredibly risky. A design can be delayed for weeks because a critical component is suddenly end-of-life (EOL) or a key trace is found to have signal integrity issues.

Integration shifts these critical tasks left, making them part of the active design process.

- Up-To-Date Supply Chain: Engineers can see the latest pricing, stock, and lifecycle data from data platforms like Octopart, Z2Data, or SiliconExpert while they are choosing parts in the schematic.

- Integrated Simulation: SPICE analysis or signal integrity checks can be run directly from the schematic and layout, providing instant feedback on design performance.

This approach prevents entire categories of design re-spins.

The Double Win: Technical and Operational Efficiency

According to industry analysis from firms like the Aberdeen Group, which found that 65% of companies cite "increasing product complexity" as their top challenge, teams using integrated platforms see significant reductions in re-spins and faster time-to-market. This research shows that companies adopting integrated practices see tangible results, including a 2.9x reduction in respins, getting to market an average of six weeks faster, and saving over $80,000 per design.

- Technical Efficiency is about doing the design correctly with fewer errors.

- Operational Efficiency is about doing the project smoothly with less friction.

A truly integrated system delivers both:

|

Efficiency Type |

What It Is |

Example in an Integrated Flow |

|

Technical |

Doing the design correctly. |

Running integrated signal integrity analysis; Native 3D clearance checking; Using one library for sch/PCB. |

|

Operational |

Doing the project smoothly. |

Cloud-based collaboration; Automated data sync with PLM; Streamlined manufacturing outputs. |

Altium Agile Teams: Scaling Speed with Structure

This balance of technical and operational efficiency is exactly what Altium Agile Teams is built to deliver. As products, teams, and compliance demands scale, speed alone is no longer enough. What teams need is speed with structure and the ability to move fast without losing control, trust, or repeatability.

Altium Agile Teams brings people, processes, and data into alignment. Instead of relying on ad-hoc coordination, manual handoffs, or external spreadsheets, teams work from a single, secure, cloud-based platform designed for connected hardware development at scale.

With Altium Agile Teams, organizations can:

- Standardize without slowing down: Built-in workflows for reviews, approvals, and releases add consistency and traceability, while still allowing engineers to collaborate in real time.

- Scale collaboration safely: Role-based permissions, audit trails, and lifecycle controls ensure the right people have the right access without introducing friction or blocking progress.

- Connect the full product team: Electrical, mechanical, procurement, manufacturing, and program stakeholders all collaborate around the same live design data, reducing misalignment and late-stage surprises.

- Maintain flexibility as complexity grows: Teams can adapt workflows, permissions, and processes as projects evolve, without breaking governance or disrupting active work.

The result is an environment where startup-like velocity and enterprise-grade control reinforce each other instead of competing. Altium Agile Teams turns organizational complexity into a competitive advantage, allowing hardware teams to deliver sophisticated products faster, with fewer errors, and far less operational drag.

This is how modern electronics teams scale speed with confidence, clarity, and control.

See what speed with structure looks like in practice. Start a free trial of Altium Agile Teams and explore how connected workflows, governed collaboration, and real-time visibility can transform the way your hardware team designs and delivers products.