Managing Electronic Component Obsolescence With a Unified Data Solution

If components stayed competitive forever, your smartphone would run on vacuum tubes. Component obsolescence is an essential part of electronics. Although it is incremental, it represents an advance in technology. However, component obsolescence can also create pain points for PCB designers, especially when they don't use the right components and obsolescence management tools.

PCB designers often lack the supply chain visibility essential for effective obsolescence management. Designers and electrical engineers need comprehensive part information, including up-to-date obsolescence risk data, within their PCB design software. With the right data management solution, they can import component lifecycle data directly into their design documents. Altium provides just this type of data management environment. It gives design teams the electronics obsolescence information they need to manage electronic component obsolescence and collaborate on up-to-date designs.

Every component will go obsolete eventually, and no component has an infinite lifetime.

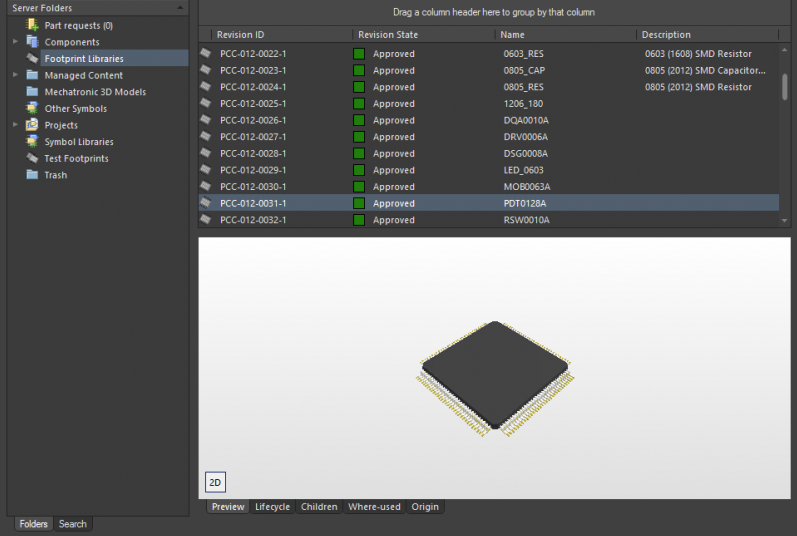

This doesn't just refer to an electronic component's operational lifetime. Eventually, a given component will be replaced with a new version, and designs will need to be updated with fresh components to ensure a longer useful lifetime. Component updates force more than just replacing components within a design; they force a design team to update their PCB libraries so that they have the most recent data on their components.

This means that replacements for the EOL parts could have a new schematic symbol, printed circuit board footprint, mechanical model, or simulation model within your ECAD software. Any of these changes will affect your design and require modifications to your board, bill of materials, and fabrication files. With the untold number of electronic components available on the market, electronic parts obsolescence management is already difficult. PCB designers need supply chain visibility throughout the design process and integrated obsolescence management software tools if they want to avoid an unnecessary redesign.

In this article, we’ll explore the challenges electronics development projects face with managing electronic component obsolescence. We’ll see how obsolescence management software, supported by integrated electronic component lifecycle data, reduces obsolescence risk and accelerates time to market.

Identifying Problems in PCB Obsolescence Management

Some components, like passives, aren't updated as often as integrated circuits, and newer components are not significantly different from previous versions. However, with active components, specialized passives or semiconductors, connectors, and other electronic components, newer versions may be significantly different. The updated data in a component can include CAD data, distributor information, prices, and much more.

Whether obsolete components in a design need to be updated and replaced is up for debate, and it depends on the design's intended application and the level of obsolescence risk an EOL part creates. For some designers, including obsolete components means a design may not be manufacturable later, so it will need to be updated. For prototypes, including some obsolete components may not matter as long as they can be easily replaced later. No matter the situation, the potential for disruption by unexpected parts obsolescence means designers need the ability to quickly identify obsolete electronic components at multiple stages in the design process.

Designers who don't have the right component lifecycle management software can find themselves falling victim to any of the following problems:

Your Supply Chain Tools Only Provide Stale Component Data

Even if your PCB design software includes a component management solution, you put yourself at risk if it doesn't update lifecycle and supplier data. Effectively managing electronic component obsolescence is time-consuming and error-prone in the absence of accurate and up-to-date, electronic component lifecycle data. Changes in the supply chain can happen quickly, and some data solutions do not provide real-time supply chain updates directly within your design software. This puts you at risk of including obsolete, soon-to-be-obsolete, or end-of-life components in your design.

When this happens, you typically don't find out about the problem until your manufacturer informs you that your lead time just jumped from a few weeks to a few months. This increases your time to market and ultimately makes you less competitive. Overcoming this issue requires real-time supply chain data and obsolescence management software that any design team member can access.

Team Sharing of Design Libraries is Inefficient

Because the supply chain moves so quickly, PCB design teams working remotely can find that their libraries quickly go stale and need to be updated. Early in the design phase, every design team member needs access to verified component data, including lifecycle information. Once one designer updates their data, how can they ensure their project collaborators use the same set of design files and libraries?

In the past, designers had to rely on an unwieldy local network or email to deliver library files and share critical design data. Getting this wrong or forgetting to send the right electronic component lifecycle data can lead to unnecessary redesigns and even failed production runs. To ensure projects are completed successfully, design teams need a simple, integrated solution for managing and sharing their design data, including component lifecycle status.

Your 3rd Party Supply Chain Management Tools Don't Integrate With Your ECAD Software

You might have found a software solution or signed up for a service that provides some level of supply chain visibility and obsolescence risk management, allowing you to anticipate sourcing problems and redesigns early in the design phase. This is a much better option than waiting to send your board off for manufacturing only to find out that obsolete components make lead times significantly longer than you expected or that components are out of stock.

Unfortunately, these 3rd party component obsolescence management and supply chain visibility tools don't integrate with your PCB design software. Once you find that important component data has been updated or that a desired component will soon become unsourceable, it is difficult to quickly locate and import a suitable replacement component into your design documents. When this happens, you're stuck browsing distributor websites and updating your design documents manually.

How Altium Develop Streamlines Management of PCB Component Obsolescence

Working through any problems related to a lack of current parts data and obsolescence management requires several important component obsolescence management tools. Working with your own component information database won't do the trick, especially when it comes to ensuring that the design data in your PCB libraries remains current. Instead, you need a solution with the following features:

Supply Chain Visibility Early in the Design Process

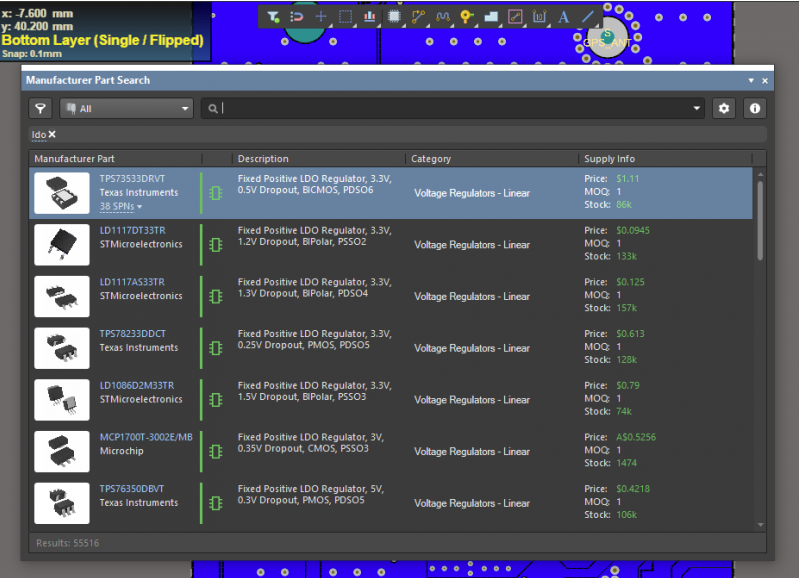

Looking at the PCB component supply chain early during design is the best way to prevent redesigns that can arise due to electronic component obsolescence. This helps you identify components that will soon reach the end of their lifecycle and adjust your sourcing strategy as necessary. You can then ensure that you find alternatives to EOL parts so the components in your board will be sourceable once it is sent off for manufacturing.

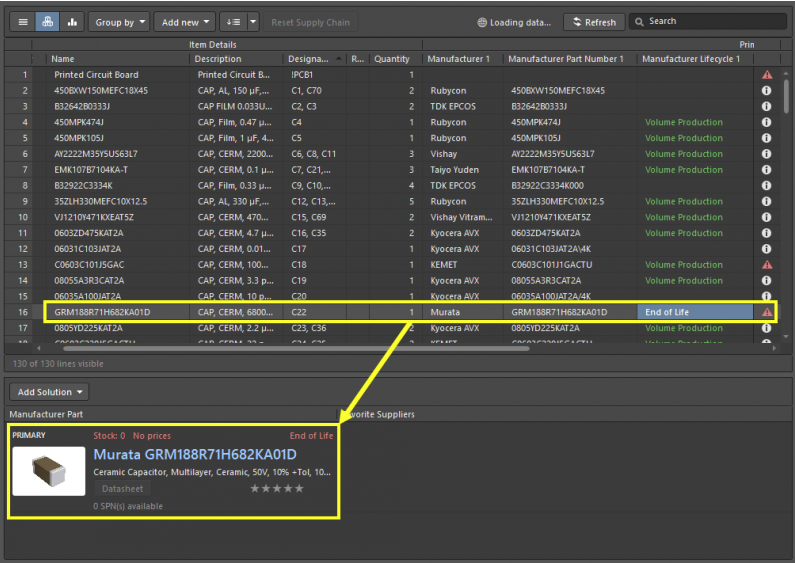

Altium Develop makes this possible by providing supplier and lifecycle data to Altium users through the Manufacturer Part Search panel. This feature is accessible in Altium Develop at all stages of the design process. A designer can search for verified parts, view sourcing information, download symbols and footprints, and spot obsolete components in a single window. This is the ideal solution for managing component obsolescence throughout the design cycle.

Integration With Your Design Features

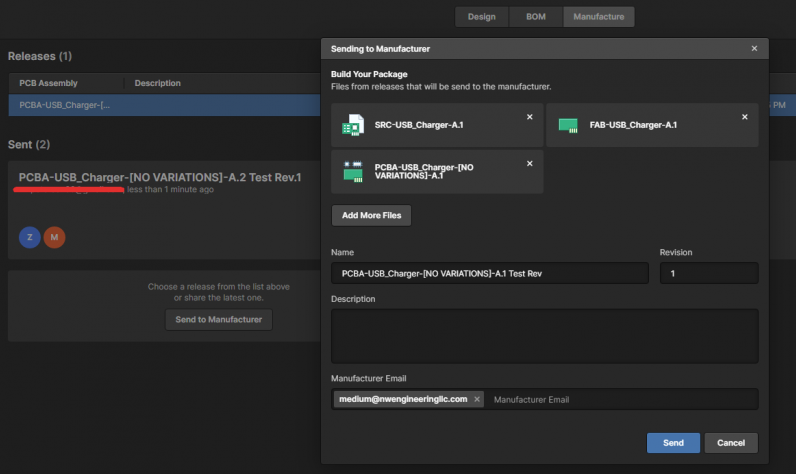

When design data is easy to share and access through the cloud, it's a simple matter to import updated data into Altium Develop. Altium was built to help design teams quickly import shared data and provide revision control for all aspects of a design. This is critical when removing EOL components during a design update or when creating a new design.

Sharing Design Data is Secure and Easy

Altium Develop world-class data management and supply chain features give your entire design team a simple way to store and share design data in a secure environment. Altium is the industry's first cloud platform for electronics data management and sharing, including electronic component lifecycle management and supply chain management. Everyone on a design team will have access to a complete set of sharing and version control features, which helps designers stay productive and ahead of component obsolescence.

Printed Circuit Design and Lifecycle Management in Altium Develop

Altium Develop solves all these component management problems and many more. Component sourcing data and lifecycle data are available within Altium Develop, and this same data is available through your web browser. In addition, you can store, share, and collaborate through the cloud.

- Altium Develop complete suite of layout and management tools is integrated into a single platform, giving designers everything they need for circuit board design and managing component obsolescence in a single program.

- Altium Develop gives their users access to a complete solution for managing electronic component obsolescence. It's easy to share and manage design data within Altium or in a web browser.

- The fastest way to see component lifecycle changes and identify alternate parts while balancing costs is to use the BOM management capabilities in Altium Develop. These features give all team members immediate visibility into component obsolescence and the supply chain.

Learn more about supply chian management with Altium Develop BOM management capabilities.

Instead of using spreadsheets or databases for component obsolescence management, use the complete set of design features and component lifecycle management features in Altium Develop. You can take control of the design and component sourcing processes with the supply chain features in Altium's complete platform for PCB design and management.

Whether you need to build reliable power electronics or advanced digital systems, Altium Develop unites every discipline into one collaborative force. Free from silos. Free from limits. It’s where engineers, designers, and innovators work as one to co-create without constraints. Experience Altium Develop today!