AI in Product Costing: The Do's and Don'ts Most Companies Get Wrong

Every manufacturer knows that product cost matters. But calculating it accurately across global supply chains, shifting material prices, and new CO₂ targets is harder than ever. Too often, teams rely on spreadsheets or outdated tools that slow them down and make results difficult to trust.

That is where product costing software comes in. Unlike Excel or legacy systems, a modern platform standardizes calculations, centralizes data, and connects procurement, R&D, and finance around a single source of truth. It does not just make costing faster, it makes results transparent and repeatable.

And yes, AI is part of this new equation. But here is the catch: most AI implementations in costing fail because they try to replace human expertise instead of supporting it.

Why AI Belongs in Product Costing

You already use AI in your daily life, and it is becoming part of nearly every business function. Costing is no exception. The real question is how to make AI work without losing control of the logic that matters most.

Our work with leading manufacturers shows clear patterns:

- AI speeds up discovery.

- It explains cost, carbon, and margin drivers.

- It flags unusual inputs before they create costly errors.

But AI does not replace deterministic, auditable calculation models or the judgment of experienced professionals. The most effective approach uses AI to reduce friction while keeping experts firmly in charge of outcomes.

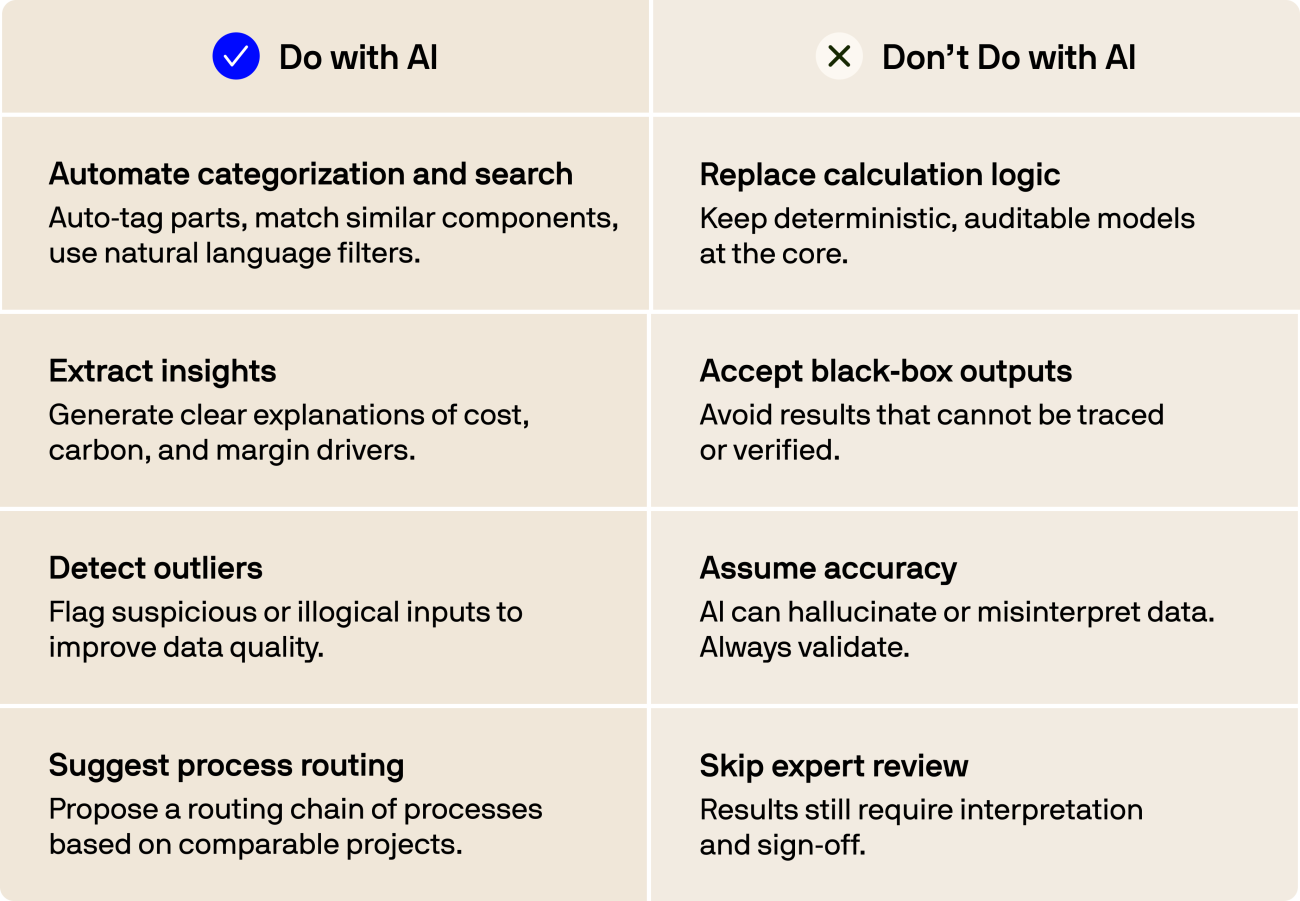

Do's and Don'ts of AI in Costing

Do This With AI

AI creates impact when used in ways that support accuracy and efficiency:

- Automate categorization and search: auto-tag parts, match similar components, apply natural language filters.

- Extract insights: provide clear explanations of cost, carbon, and margin drivers.

- Detect outliers: flag suspicious or illogical inputs to improve data quality.

- Suggest process routing: propose a routing chain of processes based on comparable projects.

Avoid This With AI

AI introduces risk if applied where transparency is essential:

- Replacing calculation logic: keep deterministic, auditable models as the foundation.

- Accepting black-box outputs: discard results that cannot be traced or verified.

- Assuming accuracy: AI may hallucinate or misinterpret data, so validation is always required.

- Skipping expert review: results still need interpretation and sign-off.

Three Principles for Using AI in Costing

Every manufacturer that succeeds with AI in product costing applies the same three principles:

- Deterministic models stay in charge. Calculation logic remains transparent, editable, and auditable.

- AI augments, it does not replace. Use it to classify, search, summarize, and flag issues.

- Traceability is essential. Every result requires a clear path from input to output.

Applied correctly, AI reduces repetitive work and surfaces the reasons behind results. Engineers gain more time to focus on high-value decisions while keeping full control.

Free Guide: Modern Cost Engineering in 2025

Get the full guide to learn how to leverage AI strategically while maintaining control over critical calculations. Download the free guide.

Why Modern Costing Software Matters

AI is important, but it is only one part of the solution. To deliver reliable results at scale, product costing software in 2025 must combine several capabilities:

- Flexible workflows that adapt to business needs.

- Centralized and transparent data that improves collaboration.

- Expert knowledge embedded across the organization.

- An AI-ready architecture that prepares teams for the future.

The winning formula is a system that is configurable, collaborative, and designed to grow with your needs.

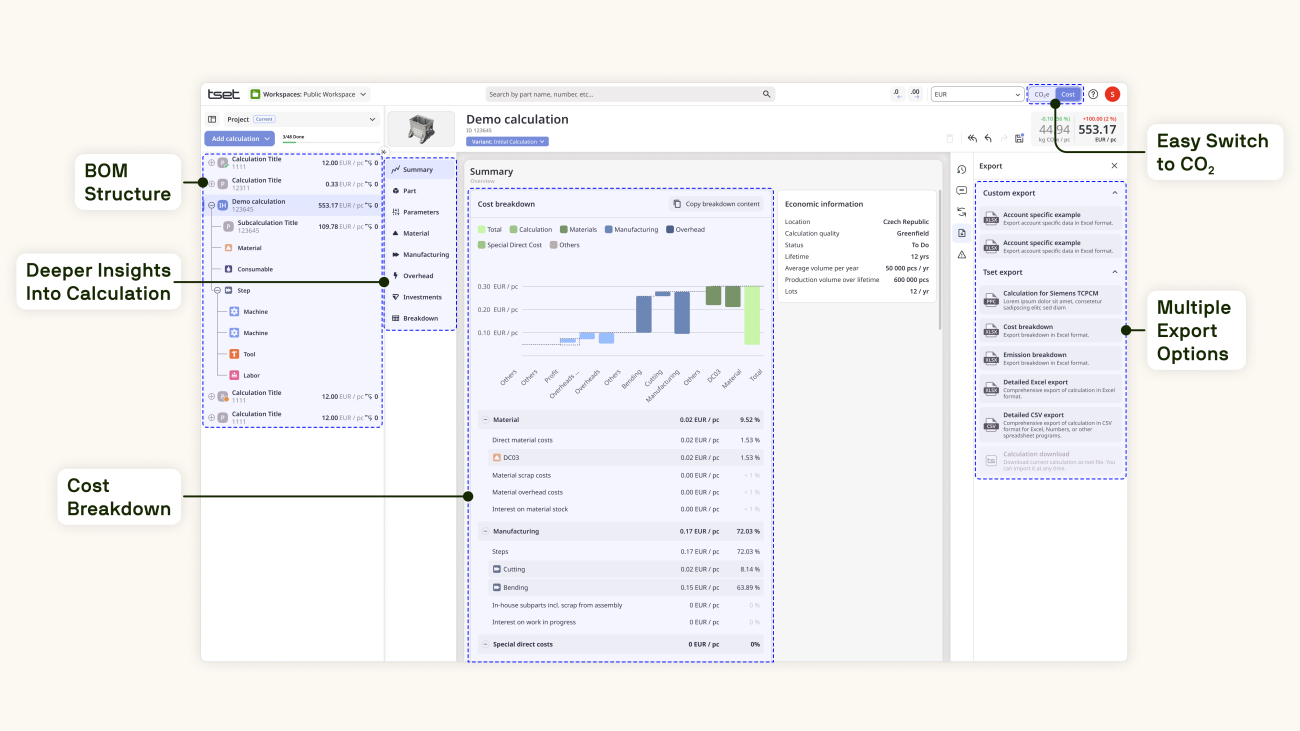

About Tset

Tset is a leading software provider for product cost and CO₂ analysis across the entire product lifecycle. Founded in 2018, Tset empowers manufacturers with cloud-based analytics that make costing faster, more transparent, and easier to scale. Trusted by global leaders such as BMW Group, AGCO, and Brose, Tset helps companies optimize both profitability and sustainability within one tool.

Conclusion

AI is reshaping the daily work of cost managers. It automates repetitive tasks, identifies risks early, and explains results more clearly. But experts remain in control, and that is how it should be. The future belongs to manufacturers who combine human expertise with modern, AI-ready software. With the right foundation, product costing becomes not just a calculation task, but a strategic advantage.