AUTOSAR Compliance and Its Impact on Automotive PCB Design

Cars are getting smarter, with more electric, connected, and self-driving features. To make these advanced vehicles safe and reliable, they need sophisticated electronics and circuit boards. Despite complexity, these systems need to be interoperable with an open standard for communication; this is where AUTOSAR (Automotive Open System Architecture) comes in.

This article explains what AUTOSAR is, how it affects PCB design in automotive electronics, and why compliance is critical for OEMs and Tier 1 suppliers.

Key Takeaways

- AUTOSAR is a standardized software architecture that lets ECUs from different vendors interoperate.

- Its adoption drives more complex, higher-performance ECUs, which in turn require multi-layer PCBs, higher MCU/memory counts, robust power management, and careful thermal and safety (ASIL) design.

- AUTOSAR-compliant designs face sourcing and engineering challenges: component compatibility, long lifecycle/obsolescence risk, thermal and signal integrity constraints, and regional supply chain pressures.

- Future automotive PCBs will center on AUTOSAR Adaptive, automotive Ethernet, AI-capable hardware, advanced cooling, stronger security, and compact/3D PCB technologies to support software-defined, smart vehicles.

What Is AUTOSTAR?

AUTOSAR is like a universal language for car software. It was created in 2003 as a collaborative effort between major car companies (like BMW and Volkswagen) and electronics suppliers (like Bosch) to solve a big problem: as cars had become more software-driven, everyone was creating their own incompatible software systems.

Today, over 300 companies worldwide, from car manufacturers to component manufacturers, work together on AUTOSAR.

AUTOSAR provides a standardized software architecture for automotive ECUs. It helps ensure interoperability and allows reuse of software across different vehicle platforms. The main goal of AUTOSAR development is to facilitate use of the same software across different car models and systems. This way, software from different suppliers can work well together, and developers can reuse parts of the software instead of starting from scratch each time.

AUTOSAR has two main standards:

- Classic Platform (CP): For real time systems like engine control, brake systems, etc.

- Adaptive Platform (AP): For high performance computing needed in autonomous driving, infotainment, etc.

What Are Key AUTOSAR Versions and Adoption Rates?

|

AUTOSAR |

Release |

Adoption Rate |

Key Features |

|

Classic Platform |

2003 |

80% (Legacy vehicles) |

Real time, low resource ECUs (e.g., engine control) |

|

Adaptive Platform |

2017 |

50% (New EVs & ADAS) |

High performance computing (e.g., autonomous driving, infotainment) |

Why Is AUTOSAR Important?

Modern vehicles can have over 100 ECUs, and these need to communicate reliably. Without a common standard, integrating software and hardware becomes time consuming and error prone.

It is crucial for modern vehicles because it ensures:

1. Standardization across the automotive software industry

- Before AUTOSAR, every car manufacturer and supplier used different software architectures, making integration difficult.

- AUTOSAR provides a common framework, so ECUs from different vendors work together without compatibility issues.

Result: Faster development, fewer errors, and lower costs.

2. Improved safety (ISO 26262 compliance)

- Modern cars have over 100 ECUs controlling everything from engines to infotainment.

- AUTOSAR ensures fail safe operation through interoperability and redundancy, reducing risks of software failures.

Example: A brake-by-wire system must respond within milliseconds. AUTOSAR guarantees real time performance.

3. Easier software updates & upgrades

- With AUTOSAR, software can be updated separately from hardware (important for OTA updates).

- New features can be added without redesigning the entire ECU.

Tesla & EVs use AUTOSAR-based architectures for over the air (OTA) updates.

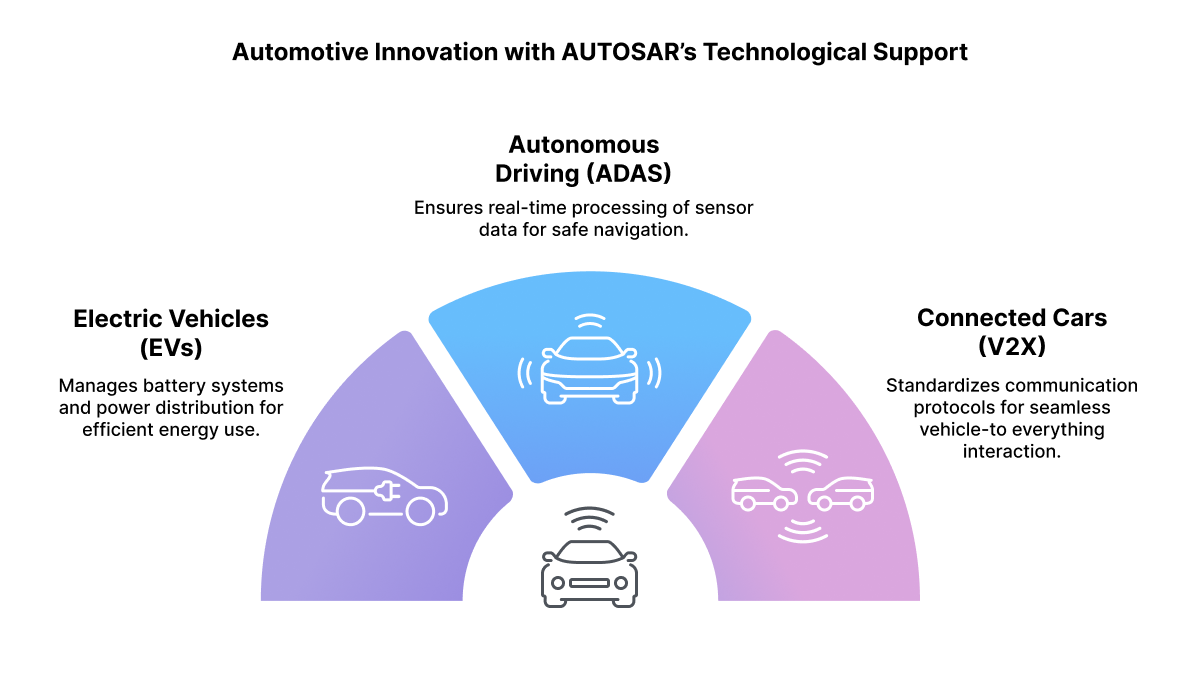

4. Advanced automotive technologies

As the automotive industry shifts toward electrification, automation, and connectivity, AUTOSAR plays a vital role in supporting these advancements. Here's why it matters:

5. Reduced development costs & time

AUTOSAR dramatically cuts development time and costs. In the past, every ECU required custom software development, an expensive and time-consuming process. Now, AUTOSAR’s standardized approach enables software component reuse, accelerating development by 30-50% according to a Bosch Automotive Report. This plug and play efficiency transforms how automotive manufacturers bring systems to market.

Cost Savings Example:

|

Development Phase |

Traditional Approach |

AUTOSAR Approach |

Savings |

|

ECU Software Design |

12 months |

8 months |

33% faster |

|

Testing & Validation |

6 months |

4 months |

33% faster |

How AUTOSAR Impacts PCB Design

While AUTOSAR mainly focuses on software architecture, it has a strong indirect influence on PCB design. Here’s how AUTOSAR affects PCB design in simple terms:

1. More PCB Layers for Complex Circuits

AUTOSAR based ECUs require more layers in PCBs to handle complex communication protocols like CAN, LIN, Ethernet, and FlexRay. A traditional engine control PCB had 6 layers, but an electric vehicle (EV) battery management PCB with AUTOSAR needs 10+ layers.

2. Hardware Software Decoupling

Traditionally, automotive ECUs were designed with tight coupling between hardware and software, making upgrades difficult. AUTOSAR introduces a layered architecture, separating application software from hardware dependencies. This flexibility is especially important for suppliers who build ECUs for multiple OEMs.

|

AUTOSAR Impact on PCB Design Elements |

||

|

Design Element |

Non AUTOSAR ECU |

AUTOSAR Compliant ECU |

|

MCU Count |

1 |

1–2 (dual core or redundant) |

|

Memory |

256 KB–512 KB |

1 MB–2 MB Flash |

|

Layer Count |

2–4 |

4–6 |

|

Heat Management |

Basic |

Required (thermal vias, pads) |

|

Power Supply |

Single LDO |

Multi rail PMICs |

|

Safety Compliance |

ISO 9001 |

ISO 26262 (ASIL B–D) |

|

Diagnostic Support |

Minimal |

Full UDS stack |

|

Cost |

$10–$15/unit |

$20–$40/unit |

3. Increased Component Requirements

With AUTOSAR, each ECU is required to support additional features such as communication systems like CAN, LIN, and Ethernet, diagnostic protocols like UDS, the ability to receive software updates over the air (OTA), and safety functions that meet ASIL standards as defined by ISO 26262.

This means more microcontrollers, memory, power management ICs, and connectivity chips must be integrated on the PCB, increasing the component density and complexity.

Example: A typical non AUTOSAR ECU used to need about 80 components, but an AUTOSAR compliant ECU may require 120–150 components.

4. Safety & Redundancy

AUTOSAR supports ASIL (Automotive Safety Integrity Level) certification. Higher ASIL levels (C/D) require redundancy on the board.

To meet these needs, engineers must plan for dual core MCUs, extra watchdog circuits, and isolated signal paths, adding complexity to PCB layout and BOM planning.

Market Trends & Data

The global automotive PCB market was valued at $6.0 billion in 2023 and is expected to reach $9.2 billion by 2030, growing at a CAGR of 6.2%. A key driver of this growth is the adoption of AUTOSAR in modern vehicles.

Challenges in AUTOSAR Compliant PCB Sourcing & Designing

As PCBs become more complex, sourcing & designing becomes more critical. Key challenges include:

1. Component Compatibility and Compliance

- Challenge: Sourcing ECUs, microcontrollers, and software stacks that are AUTOSAR compliant (Classic or Adaptive Platform).

- Impact: Limited supplier pool, especially for Adaptive AUTOSAR.

- Buyer's Concern: Ensuring long term availability of chips that support required memory, processing power, and functional safety (ASIL levels).

2. Thermal Management

- Challenge: High performance processors and SoCs used in AUTOSAR platforms generate significant heat.

- Impact: Requires the implementation of effective thermal design strategies, such as heat sinks, thermal vias, and copper thickness optimization.

- Designer’s Concern: Managing thermal performance without increasing board size or BOM cost; ensuring reliability across varying ambient conditions.

3. Extended Development and Qualification Cycles

- Challenge: Hardware software co development requires early sourcing and locking of components.

- Impact: Risk of obsolescence or specification mismatch during development.

- Buyer's Concern: Managing lifecycle risks and ensuring parts availability for 10–15 years.

4. Signal Integrity Issues

- Challenge: High speed communication protocols like Ethernet demand controlled impedance and minimal noise for reliable performance.

- Impact: PCB layout becomes more complex due to requirements for impedance matching, differential pair routing, and isolation.

- Designer’s Concern: Ensuring signal integrity while meeting space, layer count, and EMC constraints; dependency on advanced simulation tools and SI/PI analysis.

5. Regionalization and Supply Chain Risk

- Challenge: Ensuring resilient supply chains for strategic semiconductors and software partners.

- Impact: Limited sourcing options within specific geographies due to IP control or export restrictions.

- Buyer's Concern: Aligning with regional initiatives (e.g., EU Chips Act, Make in India) while ensuring AUTOSAR compliance.

Future Trends in AUTOSAR and PCB Design

1. AUTOSAR Adaptive for Smart Cars – Cars now use AUTOSAR Adaptive for advanced features like self-driving and wireless updates, requiring powerful chips and multi core PCB designs.

2. Faster Data with Automotive Ethernet – Ethernet is replacing older CAN/LIN networks for quicker communication, so PCBs need better wiring and signal control.

3. AI in Cars – AI helps with safety systems and maintenance, meaning PCBs must support special AI chips for fast decision making.

4. 3D-Printed & Compact PCBs – New manufacturing methods allow smaller, custom shaped circuit boards with parts built inside to save space.

5. Better Cooling for High Power – As electronics get more powerful, PCBs need smarter cooling like heat sinks and thermal pathways.

6. Stronger Security – Connected cars need extra protection, so PCBs must include security chips and follow safety standards.

The future of automotive PCBs lies in high-performance computing, ultra-fast connectivity, and intelligent systems. As vehicles evolve into software-defined platforms, PCB innovation will be crucial for enabling next gen features while ensuring reliability, efficiency, and security in tomorrow's smart mobility solutions. Next time your car automatically brakes for a pedestrian, remember there’s an AUTOSAR compliant PCB making it happen!