Beyond Schematics: PCB Process Engineer

Are you curious about what goes into creating the electronic devices we use every day? Do you want to know more about the people who make it all possible? In this series, "Beyond Schematics," we will be exploring various essential roles within the electronics industry. Today, we're taking a closer look at PCB Process Engineers. The Global Consumer Electronics Market size is estimated to exceed USD 1063.39 billion by 2030 and grow at a CAGR of 4.62% during the forecast period (2023-2030). It is estimated that the average volume per person in the Consumer Electronics market is expected to amount to 1.08 pieces in 2023, with ongoing growth to follow (GlobeNewsWire). Plus, this estimated growth is expected to rapidly increase with the continued advancement of technologies such as Artificial Intelligence (AI), Internet of Things (IoT), Wi-Fi, Bluetooth®, Augmented Reality (AR), Virtual Reality (VR), and cloud computing.

This rapid growth in the electronics industry places unprecedented demand on the people behind the scenes advancing our technology. Join us in our new series, "Beyond Schematics" where we will be exploring various essential roles within the electronics industry. Revealing the challenges and responsibilities of the professionals that play key roles in the industry. To kick off the series we are looking at the critically important role of a PCB Process Engineer.

The Demands and Responsibilities of a PCB Process Engineer

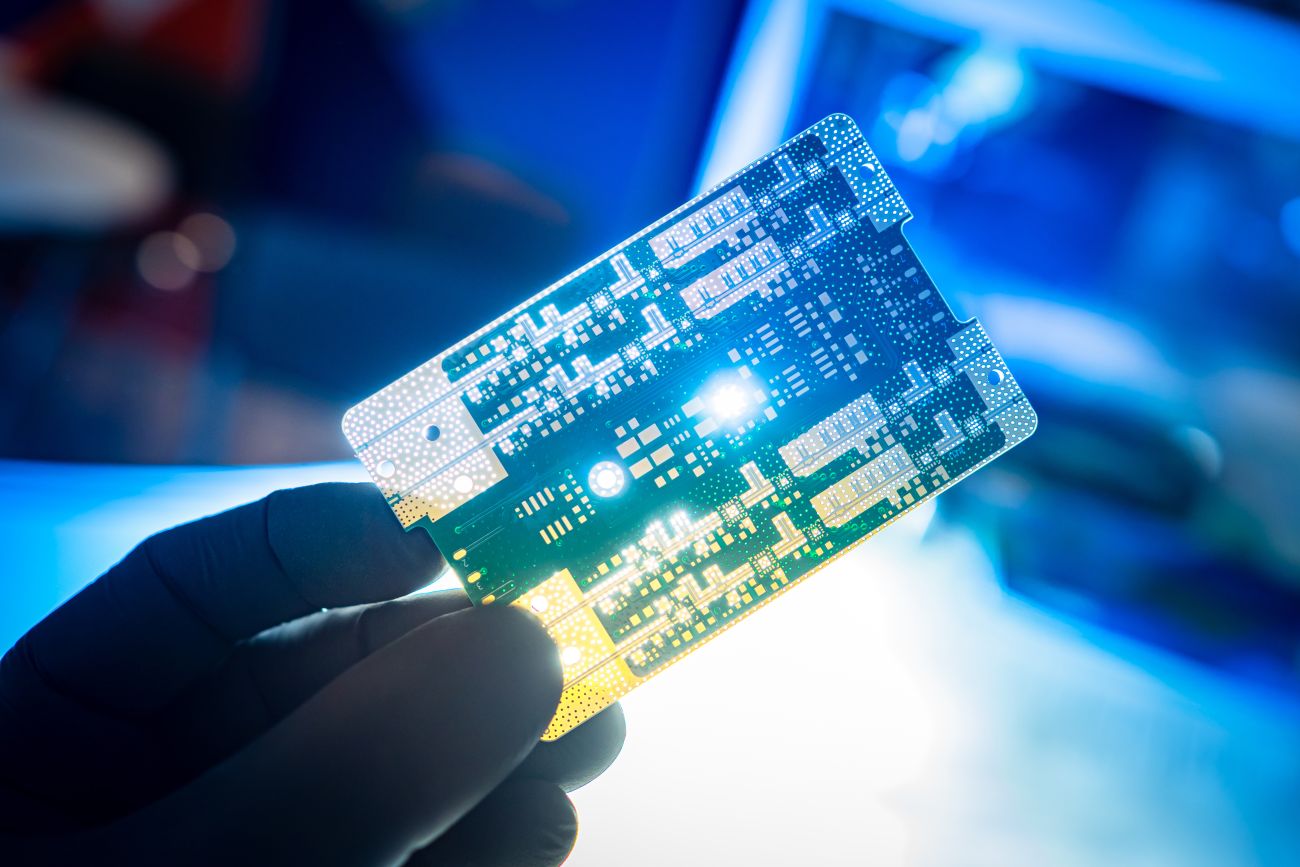

Today, we're taking a closer look at Printable Circuit Board (PCB) Process Engineers who play a pivotal role in the electronic components industry, ensuring the seamless development and production of high-quality PCBs. These specialized professionals face a myriad of challenges in their day-to-day work, ranging from keeping up with evolving technologies to maintaining strict quality standards. This article delves into the responsibilities of a PCB process engineer and explores the challenges they must navigate in the rapidly advancing electronics industry. Join us as we dive deeper into how this essential role is shaping our technological world!

The Work

PCB process engineers collaborate closely with design engineers and are responsible for optimizing PCB designs to ensure they meet specific requirements and can be efficiently manufactured. They assess component placement, trace routing, and thermal management to optimize the design for both performance and manufacturability. This includes ensuring that the PCBs meet all quality standards by establishing and implementing rigorous quality control protocols, inspecting PCBs at various stages of production, and addressing any defects or issues that arise. By continually monitoring and improving the manufacturing process, they strive to maintain the highest quality standards. This includes playing a vital role in maintaining and improving the manufacturing process to ensure that it is as efficient and effective as possible, as well as troubleshooting any issues that may arise. When possible, they work to implement new technologies, equipment, and techniques to streamline the manufacturing process and maintain a competitive edge in the industry.

Proficiency in an Electronic Design Automation (EDA) software (such as Altium Designer) is essential to the role of a PCB process engineer and is used to create PCB designs and streamline the process of designing, and simulation, while also ensuring that components will fit within the board’s physical constraints. Altium Designer is a popular EDA software that offers a comprehensive suite of tools for PCB design, including schematic capture, layout design, and design verification.

In order to be able to understand the functionality of the board design and manage the manufacturing process they must be knowledgeable in a variety of different materials and substrates that are used in the creation of the circuit boards, including FR4 glass epoxy, polyimide film, flexible circuits, and solder masks. PCB process engineers must also be well-versed in regulatory standards and safety protocols to ensure the entire process, from the design to the manufacturing of a PCB, is safe and meets country-specific regulations while ensuring that their designs adhere to industry standards for cost-effectiveness and reliability.

The Challenges

Like any industry, there are challenges that PCB Process Engineers face in their day-to-day work. The electronics industry is marked by rapid technological advancements, requiring PCB process engineers to stay up-to-date with the latest innovations. This involves continuous learning and adapting to new design and manufacturing techniques, materials, and equipment, which can be a daunting task. Some of the biggest changes in new technology is the drive to be smaller, faster, and lighter. The demand for electronic devices to become increasingly compact pushes PCB process engineers to find ways to accommodate shrinking component sizes. This requires innovative design solutions and advanced manufacturing techniques to ensure that PCBs can support smaller components while maintaining high-quality standards.

Making changes to a PCB design requires navigating a complex landscape of environmental and regulatory requirements, which can vary across different regions. Ensuring compliance with these regulations is crucial to avoid fines, legal issues, and potential damage to a company's reputation. Working within these strict regulations can impact the time to market. PCB process engineers often work under tight deadlines and budget constraints. They are often tasked with balancing the need for rapid production with the requirement for high-quality PCBs while considering the complexity of modern electronics.

Industry Trends Impacting a PCB Process Engineer

1. The use of flexible and lightweight materials: In many cases, traditional rigid PCBs are being replaced by flexible and lightweight alternatives made from materials such as polyimide, PEEK, and FR4. This trend is being driven by the need for lighter and more compact electronic devices. As a result, PCB process engineers must be up to date with the latest manufacturing methods and materials.

2. The rise of wearable electronics: Wearable electronics are becoming increasingly popular, especially in the consumer market. This trend is driving demand for smaller and more flexible PCBs. As a result, PCB process engineers are more often required to have experience with miniaturization techniques.

3. The increasing use of thermal management: Thermal management is becoming increasingly important in electronic devices as they become smaller and more powerful. This trend is driving demand for innovative cooling solutions such as liquid cooling and embedded heat sinks. As a result, PCB process engineers must be familiar with thermal management principles and practices

4. The growing demand for higher-density boards: As electronic devices become more complex, there is an increasing demand for higher-density PCBs that can accommodate greater functionality and connectivity. This trend is driving demand for advanced manufacturing techniques such as laser drilling, microvias, and high-density interconnects. As a result, PCB process engineers must have a working knowledge of these technologies.

5. The emergence of the Internet of Things (IoT): The IoT is driving demand for smaller, smarter, and more connected electronic devices. This trend is creating opportunities for the development of printed circuit boards with multiple layers and embedded components such as sensors and actuators. As a result, PCB process engineers must be able to design and manufacture sophisticated multi-layer boards with embedded components.

The Rewards

Becoming a PCB process engineer offers several advantages and can be a fulfilling career choice for individuals with a strong interest in electronics and a knack for problem-solving. As the electronics industry continues to grow and evolve, it is also driving the demand for skilled PCB process engineers. Their expertise is essential to the successful development and production of electronic devices, making them a valuable asset in the job market. With the dynamic nature of the industry, there are ample opportunities for PCB process engineers to continually learn and adapt to new technologies and techniques. This constant evolution fosters professional growth and development, keeping the role engaging and challenging.

The PCB process engineer career path allows for contributing to cutting-edge advancements that can improve people's lives and drive progress in various industries. They work closely with other engineering teams, fostering a collaborative environment. This teamwork, combined with the problem-solving nature of the role, can be highly rewarding and satisfying for individuals who enjoy tackling challenges and working with others.

PCB engineers are a highly sought-after commodity and while their role may be ever-evolving they won’t be going anywhere in the foreseeable future, in fact, demand for these professionals is predicted to increase at a rapid rate. As new trends emerge in the electronics industry, PCB process engineers will continue to play a vital role in the industry and in shaping the future of electronic components.

This article has explored the role of a PCB Process Engineer, and highlighted their responsibilities and the skills needed to excel in this position. With an understanding of the duties associated with this role and what it takes to be successful, interested individuals can begin their journey into exploring how to become part of the electronics industry. Whether as a PCB Process Engineer or in some other capacity, there is an opportunity for anyone interested in pursuing a career related to electronic components and assembly.