From Concept to Production: Mastering Component Selection for Scalable Manufacturing

In electronics design, the leap from a promising prototype to full-scale production is where many projects stumble. What looks straightforward on paper often turns into a minefield of unexpected challenges and budget overruns. McKinsey research suggests that supply-chain disruptions lasting one month or longer occur about every 3.7 years and can wipe out 45% of one year’s profits. The key to avoiding these pitfalls is choosing components that support manufacturing scalability from the very start, making access to comprehensive component data critical.

Octopart, an intelligent search platform, helps engineers discover, validate, and manage electronic components with up-to-date pricing, availability, and specifications for millions of parts. Combined with Octopart's free BOM Tool, design teams can work with production in mind, making each part selection both technically sound and supply-ready.

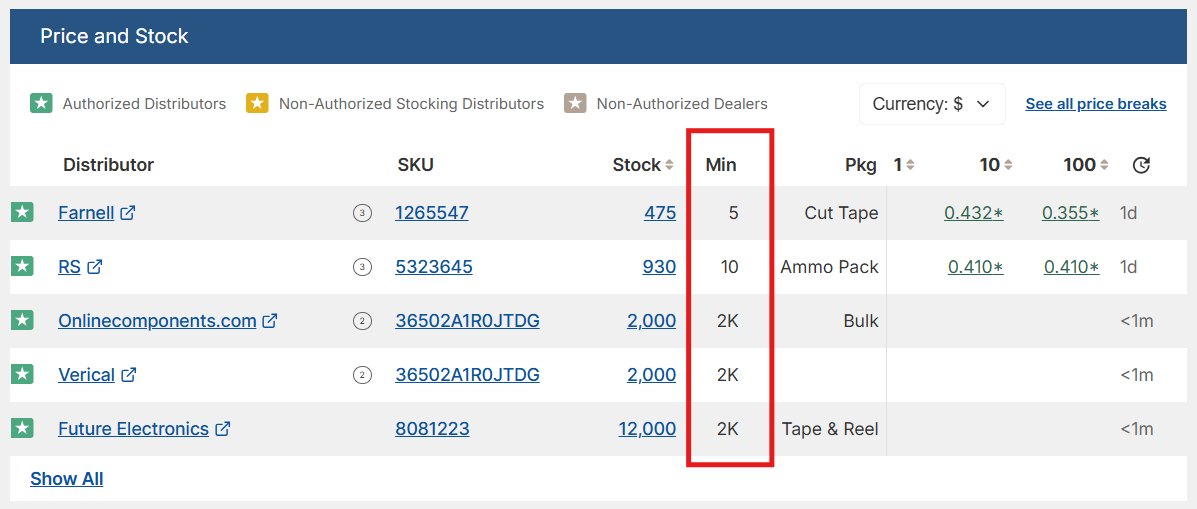

Align MOQ With Production Goals

Minimum order quantity (MOQ) requirements can make or break a production plan. Forward-thinking teams avoid overbuying and excess inventory by selecting components whose MOQs match anticipated build volumes. To help achieve this, Octopart displays distributor and manufacturer MOQs directly alongside part data, giving engineers a clear view during the design stage. Early visibility also helps teams understand the full cost implications as they move into pricing analysis.

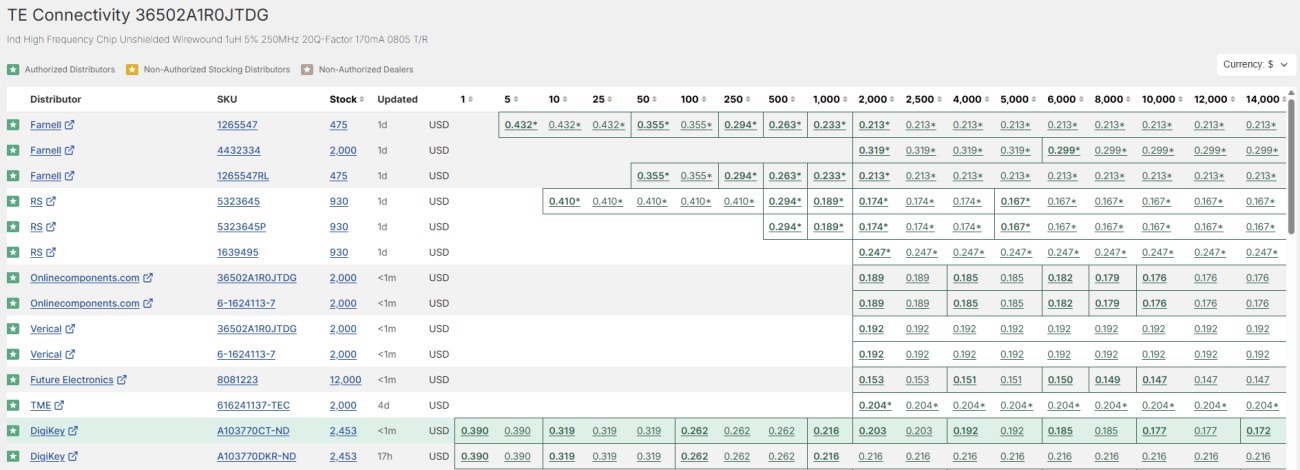

Use Pricing Tier Analysis For Cost Scaling

Pricing tiers directly impact the economics of scaling. When you can see how the cost per unit changes with order volume, it becomes easier to select parts that remain profitable at higher production runs. Octopart’s up-to-date pricing data allows side-by-side comparisons of tiered pricing from multiple suppliers. This comprehensive view supports smarter decisions that protect margins without compromising performance or quality across different suppliers.

Diversify Suppliers to Reduce Risk

Relying on a single source for a critical component introduces unnecessary risk. McKinsey survey reports that 73% of supply‑chain leaders have moved toward dual‑sourcing and 60% are regionalizing their supply base, while a separate Deloitte & Manufacturers Alliance study found that 81% of manufacturers actively pursue multiple and regionally diverse suppliers. Octopart makes supplier diversity simple by displaying multiple qualified sources for each part. Teams can protect themselves against shortages, allocation events, and abrupt price changes by identifying and approving alternative suppliers early. The built-in resilience keeps production moving even when one supplier’s inventory runs dry. However, having multiple suppliers means understanding the timing constraints each one brings.

Forecast Lead Times for Smoother Schedules

Long-lead components can derail production schedules if not accounted for early. The manufacturers' lead-time data helps teams plan around these constraints, allowing procurement to order in time to meet build deadlines. The proactive approach keeps projects on track and aligns engineering and supply chain teams on delivery expectations. The next consideration after timing is securing the right package options.

Optimize Packaging and Availability

Package choice can affect everything from assembly processes to sourcing flexibility. With Octopart, you can filter for in-stock packages across multiple distributors to find variants that are both manufacturable and available at scale. You can minimize risks and surprises when transitioning from a small prototype run to mass production.

Building Production Resilience From Day One

Scalable manufacturing begins with sourcing decisions that balance design requirements, cost control, and supply stability. Teams can confidently move from concept to production by utilizing Octopart for MOQ alignment, tiered pricing insights, supplier diversity, lead-time forecasting, and package optimization. The result is faster time-to-market, reduced procurement risks, and a design that's ready to succeed at any scale.