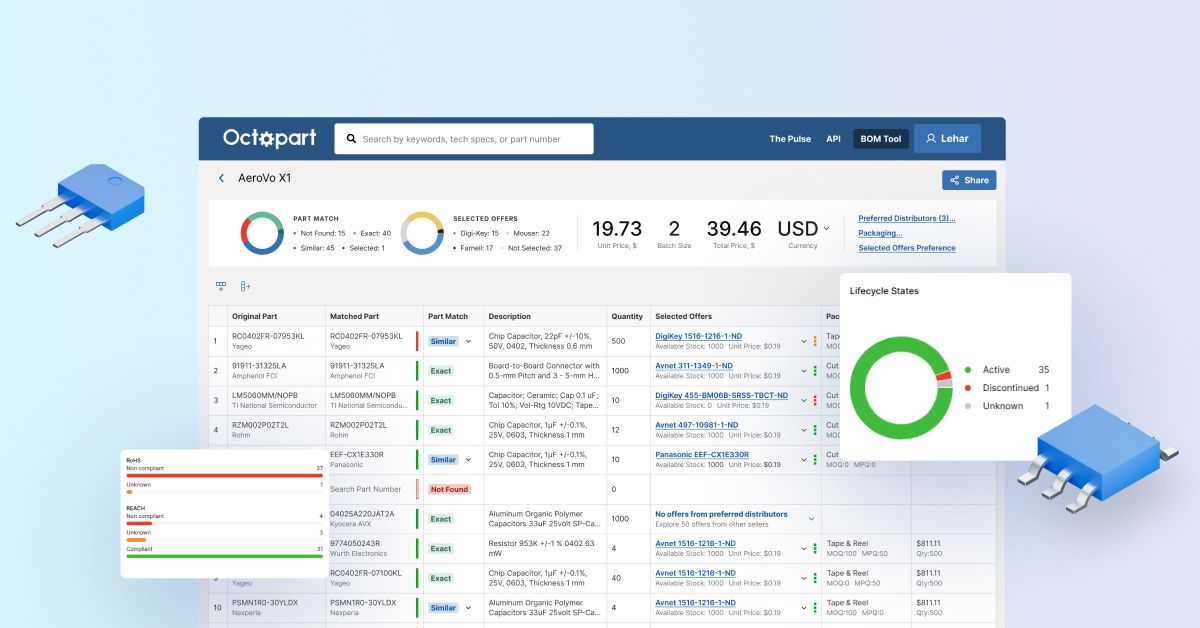

How to Source Alternate Parts with Octopart BOM Tool

Welcome to part two of Octopart’s Expert Insights on Sourcing BOMs series! In this episode, Joel Austin and Zach Peterson dive into how you can efficiently source alternate parts using the Octopart BOM Tool. From identifying lifecycle risks to checking compliance and replacing discontinued components, this walkthrough shows how to make smarter sourcing decisions.

- Didn’t catch the first episode? Click here to see how to simplify component sourcing.

How Do I Spot Parts at Risk of Obsolescence?

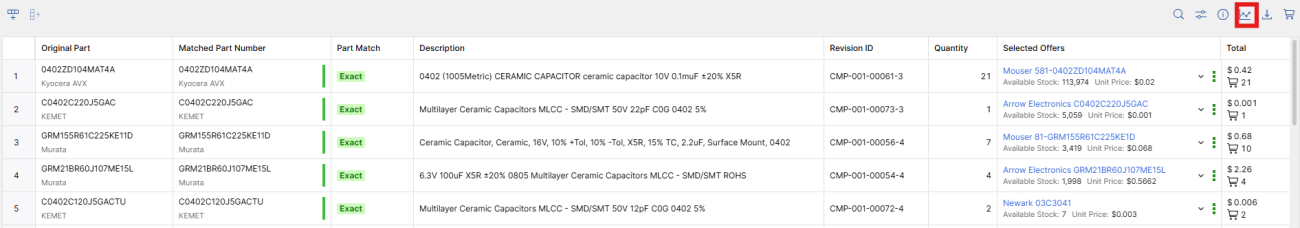

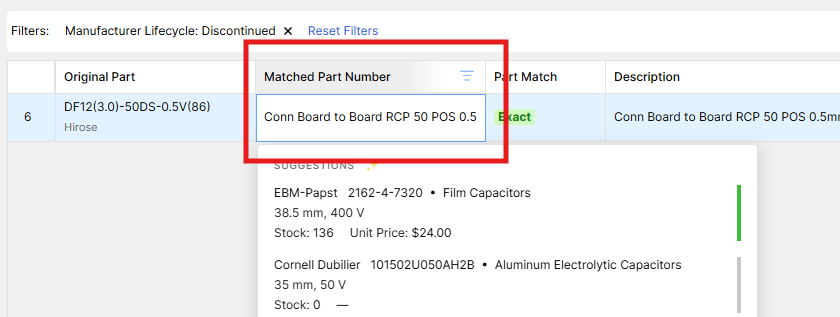

The BOM Tool makes it easy to identify lifecycle issues. Once you upload your BOM, the tool uses color coding in the Matched Part Number column to show lifecycle status at a glance.

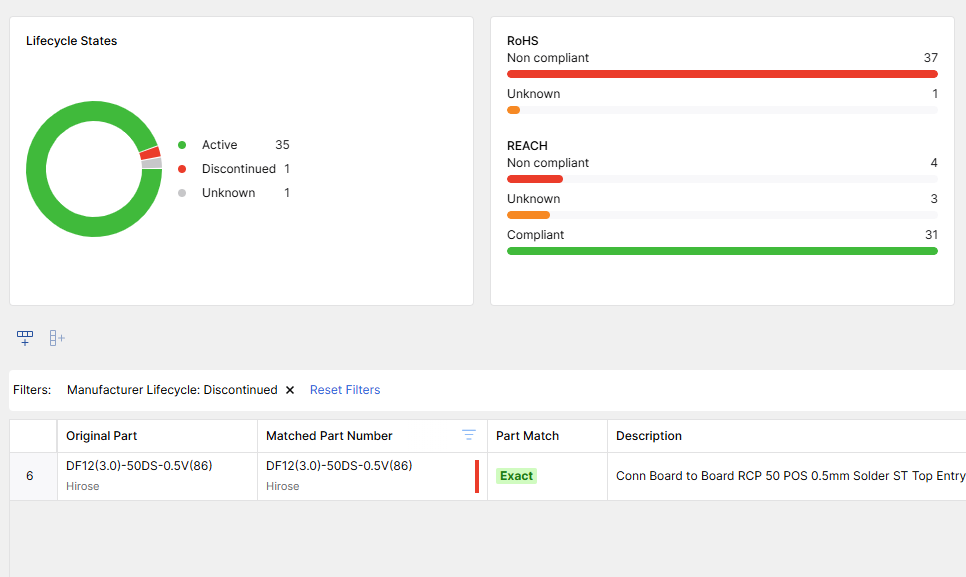

For example, if a part is marked Discontinued, you’ll know immediately that it’s unsuitable for long-term sourcing. The early warning system helps you swap out vulnerable components before they become a supply chain problem.

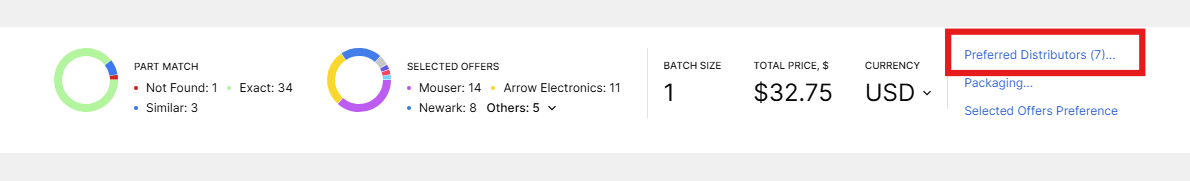

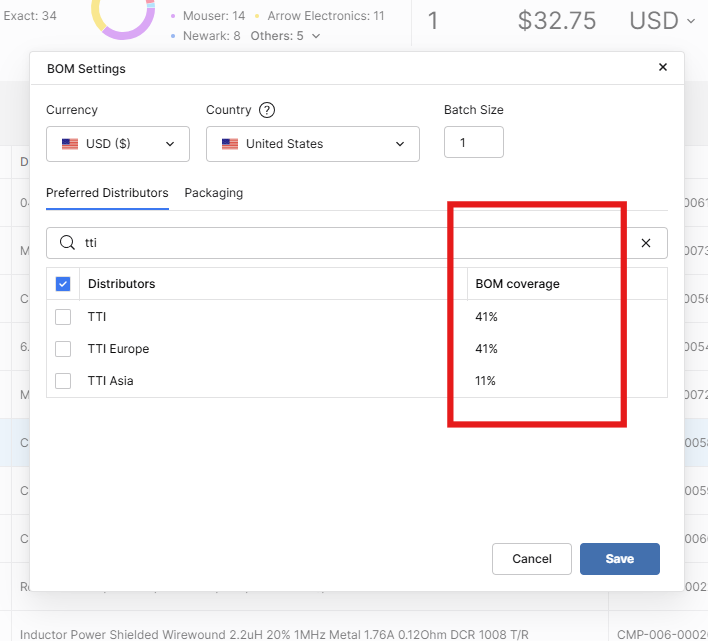

Can I Filter Parts by Preferred Distributors?

Yes, and this is where BOM Tool really shines. Under the Preferred Distributors option, you can search for and select approved vendors.

BOM Tool also provides a BOM coverage column, showing what percentage of your BOM each distributor can source. This is valuable not just for sticking to company-approved vendor lists, but also for comparing potential new distributor partners.

What About Compliance and Availability Checks?

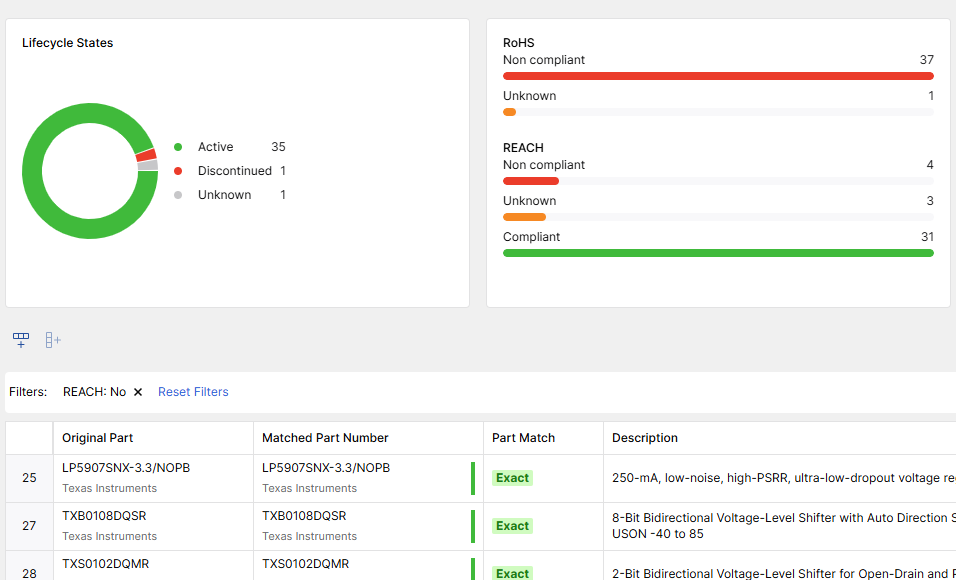

BOM Tool goes beyond simple sourcing by surfacing compliance data. The Parts Analytics tab summarizes criteria like:

- RoHS compliance

- REACH compliance

- Lifecycle status

For instance, you can see how many of your BOM parts are RoHS-compliant, which ones are unknown, and which are non-compliant. With one click, you can filter directly to the affected parts.

The same applies for discontinued items. Click the status, and BOM Tool shows you only those parts.

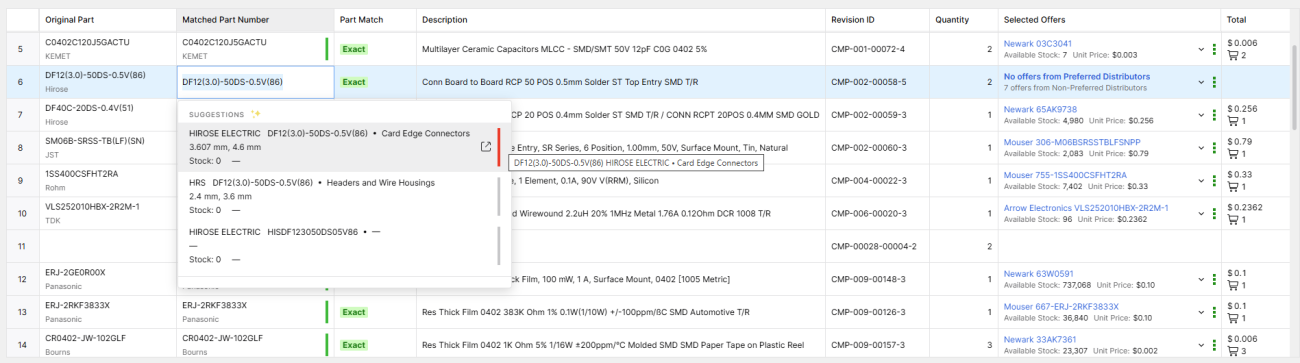

How Do I Replace a Discontinued or Risky Part?

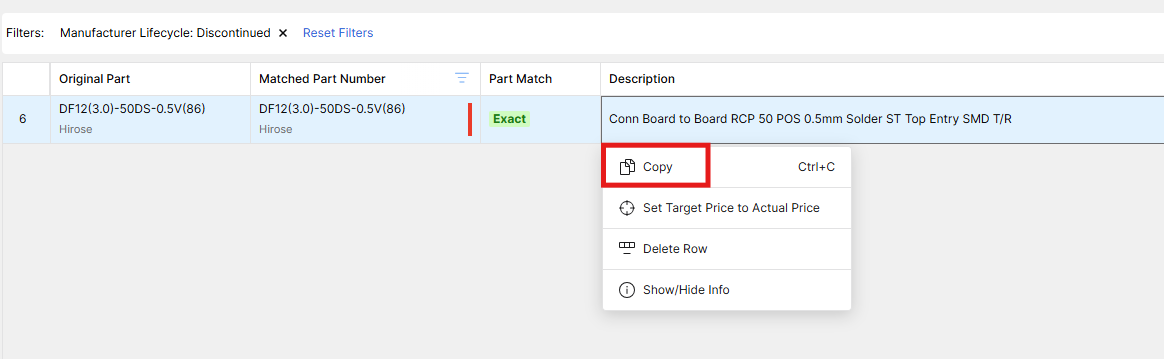

Replacing parts is fast and intuitive. Here’s how it works:

- Copy the part’s description from your BOM.

- Paste it directly into the Matched Part Number column.

- Refine the search if needed.

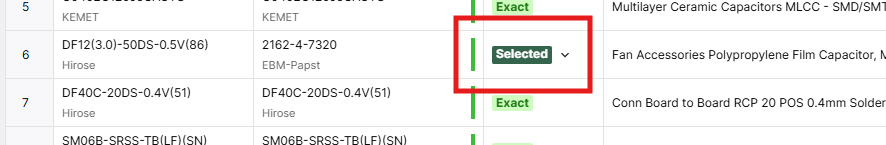

- Select a suitable alternate from the suggestions.

The BOM updates automatically. Description, offer, and price are refreshed in real time, which makes finding alternates for common components like inductors or transistors much less of a hassle.

What Happens After I Pick Alternates?

Once you’ve identified alternates, the next step is to select offers from distributors to ensure you know exactly where to buy the replacement parts and at what price.

Of course, any alternate needs to be qualified by your engineering team before finalizing, but BOM Tool drastically cuts down the manual effort of finding candidates.

Stay Tuned for the Next Episode

This walkthrough showed how to identify risky components, filter by approved distributors, check compliance, and quickly swap out discontinued parts.

In the next episode, we’ll dive into selecting offers once alternates are identified. Subscribe to our newsletter so you don’t miss the next installment and try Octopart BOM Tool today!