How to Prevent Electronic Component Shortages and EOL Components from Derailing Electronic Product Development

It’s no secret that a lack of supply chain visibility puts electronic product development projects at risk, especially when it comes to part obsolescence.

Without early insight, projects are at risk of last-minute part swaps, which can be caused by component obsolescence or electronic component shortages at any point in the supply chain. No business wants to deal with last-minute changes for the sheer fact that it delays production and delivery schedules, increasing costs or, in the worst case, resulting in contract losses.

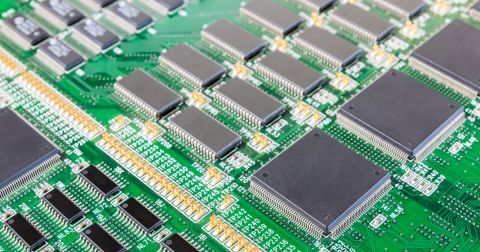

It has become clear over recent years that many disruptions to PCB design and manufacturing are rooted in supply chains. You don’t have to rewind far to notice them. Once again, we find ourselves talking about supply chain data, because it is essential for supply chain visibility and the key to proactive risk management.

Why Part Swaps Happen: Common Supply Chain Triggers

Companies lacking supply chain visibility are subject to supply chain risks that may negatively impact current and future electronic design efforts. Electrical engineers and designers looking to be more proactive in their approach to supply chain risk should prioritize improving supply chain visibility through the integration of the latest electronic component data into their design environments. As PCB designers become better-informed about supply chain risks, they can begin to see the common causes of delays or last-minute changes.

To achieve this visibility, they must know the common causes of part swaps. But, the real impact comes from this understanding: problems can arise anywhere in the supply chain, and better use of data helps preempt even the slightest changes among suppliers and customers.

Common Reasons for Part Swaps

- Discontinuation: Projects can be delayed when designers and procurement teams respond slowly to component discontinuation notices. Integrating up-to-date component lifecycle data, including component obsolescence and EOL component notices, directly into the design environment enables proactive identification of at-risk parts before they impact project timelines.

- Standards and Regulations: This challenge is somewhat dependent on the industry. For example, lack of access to legacy components often necessitates last-minute part swaps in the medical, automotive, and aerospace sectors. If designers and procurement teams fail to track evolving lifecycles and compliance requirements, such as RoHS, REACH, or FDA approvals, they find themselves experiencing costly redesigns.

- Inventory Challenges: Authorized distributors have limited inventory and frequently run out of specific part numbers. Without pre-qualified alternative parts or pre-approved backup suppliers, unexpected stock-outs can force emergency redesigns. Design teams should establish multiple sourcing options during the initial component selection phase to avoid last-minute design changes.

- Specialized Components: Many high-value components, including custom ASICs and specialty processors, have limited supply sources. During high-demand periods, brokers frequently buy out authorized distributor stock and resell components at inflated prices. Teams may need to swap to alternative parts when original components become unavailable or prohibitively expensive.

The real problem lies internally; a design team’s ability to curate and manage the above factors is influenced by the information available to them. Designers who look beyond their immediate environment and encourage a deeper understanding of their external supply chain and internal procurement activities and challenges see a reduction in last-minute part swaps.

Necessary: Clearly visualize the next steps of suppliers and customers, and the changes impacting them in the future.

Optimal: Drive the supplier and customer responses to changes with greater visibility of upcoming changes, essentially becoming the "all-seeing eye."

The Component Sourcing Data You Need to Quickly Handle Part Swaps

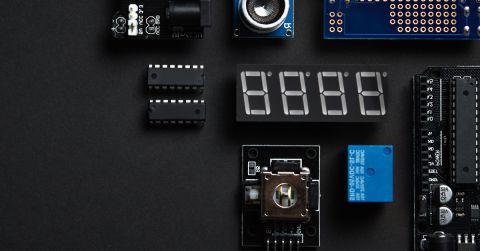

Several pieces of information will be needed in order to quickly identify a part swap and implement alternative electronic components in a design.

- Lifecycle and Inventory Status: These are the two main motivators for implementing a part swap, so the lifecycle and inventory for any part swap should also be known to the design team or procurement. That includes information about EOL components, component obsolescence, and electronic component shortages.

- Type of Alternate: There are three basic ways parts are categorized as potential replacements: direct, alternate package, and similar specification. Direct replacements have pin-for-pin compatibility and substantially similar technical specifications. Alternate packaging may be a direct replacement but in a different package and possibly a different pinout. The "similar specification" category is somewhat vague and requires some investigation by an engineer before the part can be approved as a swap.

- Available Suppliers: Some companies have limitations on where they can legally purchase parts, or they might attempt to minimize import tariffs. In other cases, some companies have preferred purchasing agreements with specific suppliers, so the alternate should be available from approved sources. This means teams need inventory data across multiple suppliers, including potentially resellers and brokers.

With the right supply chain and BOM management software linked to your PCB designs, it’s much easier to spot discontinued/out-of-stock parts and identify alternates before manufacturing. Altium gives users exactly this capability by leveraging proprietary data and 3rd party data sources. Altium can also suggest alternate parts for select part numbers, as well as inventory and supplier information for all candidate alternate parts.

Build Resilience Against Last-Minute Part Swaps

Preventing last-minute part swaps requires supply chain visibility, foresight, and proactive planning. By leveraging real-time inventory tracking, predictive analytics, and strong supplier relationships, engineering teams can anticipate risks and secure alternatives before disruptions occur.

Strategic sourcing, distributor monitoring, and compliance tracking help minimize costly redesigns and delays. Altium's integrated supply chain solutions allow teams to streamline procurement and engineering workflows, ensuring product development stays on track.

Altium combines design and supply chain data in a centralized platform to enable real-time part availability checks, lifecycle forecasting, and risk mitigation tactics that are integrated directly into the design. Product and procurement teams can make smarter decisions faster with reliable, aggregated supply chain data sources.

Interested in taking control of your supply chain management? Discover how Altium simplifies BOM management, mitigates risks, controls costs, and integrates up-to-date supply chain data.