How Engineers Are Using Multi-Footprint Designs to Stay Flexible

As supply chains dictate what’s buildable, flexibility at the component level has become a strategic design imperative.

A single-source strategy often fails to deliver the necessary ability to maintain margins in a market characterized by shortages, disruptions, and lifecycle unpredictability.

In response, multi-footprint design has gained traction as a low-effort, high-impact way to address these challenges. Ultra Librarian’s Market Data Report shows that during the recent global shortages, companies that had designed for alternate footprints were able to pivot quickly, while others faced months-long delays and costly PCB re-spins.

As a result, Deloitte’s 2025 Manufacturing Industry Outlook indicates flexible design is now widely recognized as a best practice for supply chain resilience, reducing the risk of redesigns, part shortages, and production delays. It’s a straightforward technique with an outsized return: flexibility at the layout level, built in from the start.

Why Design Flexibility Is Now a Supply Chain Imperative

While some indicators suggest a stabilizing supply chain, volatility remains the norm. As of early 2025, IPC reports that 73% of electronics manufacturers still report moderate to severe delays due to component constraints. Lytica data from February shows that semiconductors, processors, and sensors remain particularly constrained, with lead times rising over 25% month-over-month in some categories. Overall stock levels hit a low of 89% in early 2025, their lowest level since October 2024.

Although conditions have improved since 2020–2021, most 2025 outlooks, including Simcona’s, still emphasize the need for flexibility and resilience as core supply chain strategies. Manufacturers and distributors continue to prioritize adaptable sourcing strategies, supply chain diversification, and proactive inventory planning to weather ongoing challenges.

Engineers now play a central role in supply chain strategy. To create resilient designs, engineers must bake adaptability into their products from the outset, identifying alternates early and leveraging up-to-date availability and lifecycle data to design boards that can accommodate substitute components without delay.

What Is Multi-Footprint Design

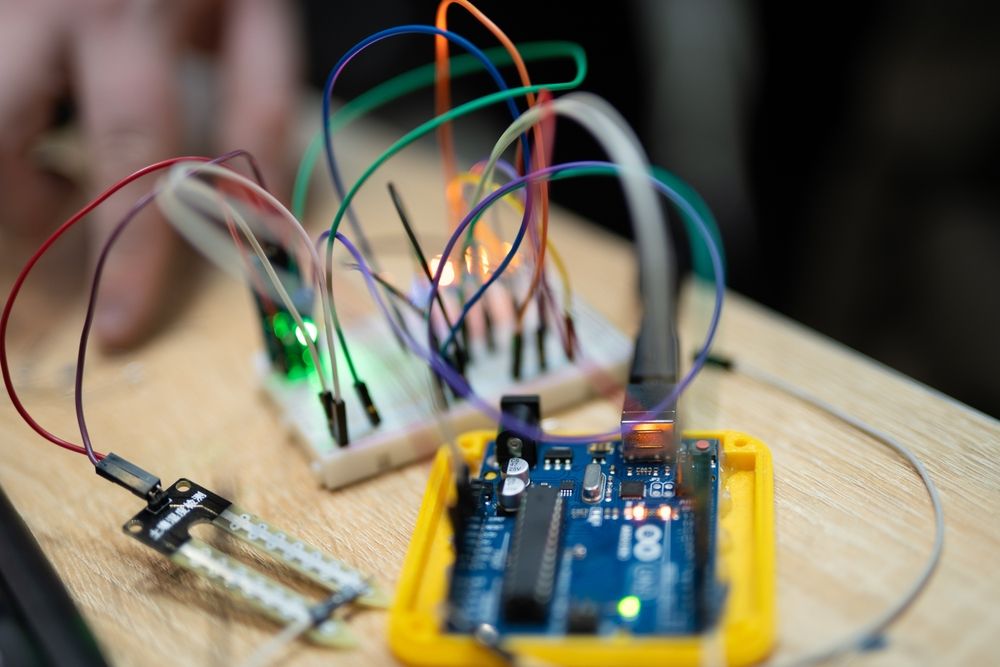

Multi-footprint design involves assigning more than one physical footprint to a logical component in a PCB layout. This technique allows engineers to physically accommodate different components. For example, an IC might come in both SOIC and TSSOP packages. By planning for both in the layout, engineers ensure they can swap in a second-source part without re-spinning the board.

In traditional design, choosing a single footprint locks you into a specific part and supplier, with no easy fallback if that part becomes obsolete or unavailable. Multi-footprint design sidesteps that risk by building in predefined layout options. The result? Faster pivots when sourcing issues arise. This flexibility can mean the difference between costly delays and staying on schedule; it’s not uncommon for project delays to result in missed revenue opportunities that may total tens of thousands of dollars or more, depending on the product and market. A single PCB re-spin can cost anywhere from thousands to tens of thousands of dollars, depending on its complexity and production volume.

How Octopart Enables Supply Chain-Resilient Design

Engineers need reliable tools to identify functionally equivalent parts, compare footprints, and verify availability. Octopart makes this possible, empowering teams to validate alternatives and design for resilience from the start.

With up-to-date insights on availability, pricing, and lifecycle status, Octopart empowers engineering teams to build resilient BOMs and layout strategies that can adapt as market conditions change. Whether you’re sourcing a drop-in replacement or planning for multiple packages, the platform provides:

- Comprehensive Search for Package Variants: Quickly explore all available footprint options for a given component. Filter by voltage, pin count, power ratings, and more to ensure compatibility across packages.

- Verified Datasheets, Footprints, and 3D Models: Access accurate, manufacturer-sourced documentation (including 3D models and PCB footprints) to design confidently across multiple packages.

- Cross-References and Alternative Part Suggestions: Not all substitutes are equal. Octopart highlights vetted, layout-compatible alternates and cross-references so engineers can find drop-in replacements fast.

- Up-to-Date Stock and Pricing Data: Availability changes fast. Octopart continuously aggregates inventory and pricing from hundreds of distributors, helping teams prioritize in-stock, spec-compliant, and cost-effective components.

This level of data visibility gives engineers the confidence that their designs are not only innovative but executable, without delays, redesigns, or late-stage surprises.

Best Practices for Building Multi-Footprint Flexibility Into Your Design

While simple in concept, executing multi-footprint design well requires forethought and coordination. These best practices can help teams maximize their benefits:

- Use Reliable Data Sources: Tools like Octopart ensure you’re designing with accurate specs, verified footprints, and up-to-date cross-references.

- Define Multiple Packages in CAD: Set up logical parts with all physical variants. Ensure clearance and routing support all included packages.

- List Approved Alternates in the BOM: Document alternate part numbers in the BOM to support procurement.

- Run DRC Checks for All Variants: Confirm that design rules accommodate each footprint. A layout that works for QFN might not work for SOIC.

- Involve Procurement Early: Supply chain input on vendor reliability and availability can shape which footprints to include.

Case Study: How Dual-Footprint LDO Design Kept Production on Track

Imagine the following scenario: Faced with ongoing supply chain volatility, a design team sought to ensure uninterrupted production for their power management circuit. Their strategy centered on selecting a low-dropout regulator (LDO) available in both SOT-23 and X2SON packages and designing the PCB to accommodate both. This dual-footprint approach allowed for seamless part substitutions without necessitating a board redesign.

The smaller 1×1-mm X2SON package was strategically placed within the SOT-23 footprint area, enabling support for both packages without increasing the board's physical size.

The pinout configuration ensured that the VIN and VOUT connections remained consistent across both packages, ensuring correct operation regardless of which package was populated.

The results? By accommodating both package types, the design effectively doubled the number of usable components, providing greater flexibility in sourcing parts. The upfront flexibility in the PCB layout eliminated the need for costly and time-consuming board re-spins when substituting components.

The key takeaway is that incorporating a dual-footprint design for the LDO not only mitigated supply chain risks but also enhanced production agility. As highlighted by Electronic Products, this approach exemplifies a practical solution for maintaining continuity in manufacturing amidst component shortages.

The Business Case for Multi-Footprint Design

Adding multi-footprint options during schematic and layout typically takes just a few extra hours, but the payoff is significant. This simple step delivers:

- Faster sourcing: Teams can pivot to layout-ready parts as availability changes.

- Fewer board spins: Avoid costly redesigns when a component becomes unavailable.

- Stronger supplier leverage: With more sourcing options, procurement teams can negotiate better pricing and reduce vendor dependence.

The impact is measurable:

- Capture revenue early and reduce labor costs: A Deloitte study found that companies embedding supply chain flexibility into product design cut time to market by 25% and reduced unplanned engineering change orders by 30%.

- Avoid production delays: According to an IPC survey, 73% of electronics manufacturers said sourcing flexibility helped them avoid moderate to severe production delays.

- Protect budgets: Design teams using multi-footprint strategies reported over 40% fewer PCB re-spins, saving tens of thousands of dollars per project, as indicated by Ultra Librarian.

The stats are pretty clear. In an industry where even a week of delay can cost tens of thousands, multi-footprint design is a small up-front investment that pays back in resilience, cost control, and faster time to market.

Start Engineering for Agility

Product development is no longer a straight line from schematic to assembly. Engineers today must think like supply chain strategists, anticipating change and designing for it.

Multi-footprint design is a practical, data-driven way to add supply chain flexibility without overhauling your workflow. And with platforms like Octopart, it’s never been easier to implement.

Back

Back