Why "Cheapest" Is Not Always Best: The Total Cost of Procurement

The electronics industry is highly competitive, especially in the pricing of electronic components. Whether in low or high-volume manufacturing, component costs often dominate total product costs. This leads some companies to base design and production decisions solely on component price tags.

However, companies must consider both tangible and intangible costs of procurement. Where parts are bought, shipped, and assembled can significantly impact total cost, beyond what’s listed on a distributor’s site. With proper supply chain tools that improve visibility, buyers can anticipate and manage true component costs, rather than focusing only on distributor pricing.

What Influences the True Cost of Electronic Components?

The true cost extends beyond the distributor’s quote. Often-overlooked expenses include shipping, inventory holding, import tariffs, customs duties, parts attrition, rework, and scrap. For example:

- Parts purchased from an overseas distributor incur import duties.

- Inventory is held before kitting.

- Parts shipped to overseas assemblers incur additional shipping and duties.

- Assemblers may require a 20% attrition buffer, effectively raising part costs.

- Finished products shipped back to the customer incur further logistics costs.

- Leftover parts may be discarded after a holding period, creating losses.

Such hidden costs often surprise buyers, especially when they’re racing to meet deadlines. Better logistical planning, deciding where to buy, ship, and produce, make those hidden costs visible. This improvement depends on pricing, inventory, and location data across the supply chain.

Looking Beyond Price With Octopart

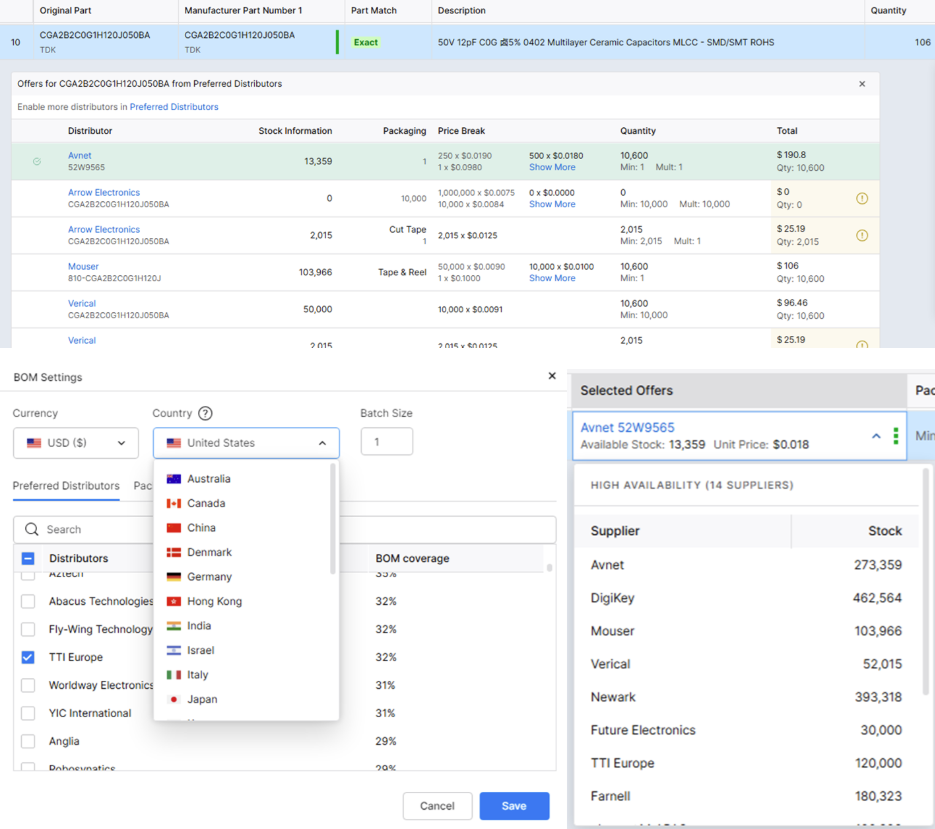

Octopart is a search engine for electronic components, providing up-to-date supply chain data, pricing, and inventory information from global distributors, resellers, and dealers. Alongside technical specifications, Octopart helps design and procurement teams select parts based on cost, availability, and functionality. This global view of the supply chain is visible inside Octopart’s BOM Tool, which functions as an easy-to-use hub for cost analysis.

This global view enables smarter decisions on where to buy, how to consign parts, and how much inventory to hold, reducing or avoiding hidden costs. Price breaks at high-order volumes are clearly visible, offering accurate per-part costs across a BOM.

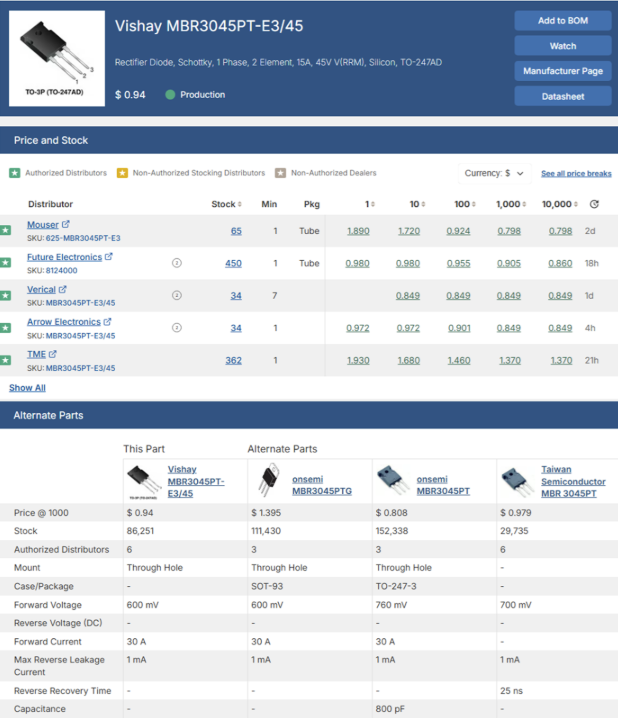

Octopart also shows compatible alternative components. Simple part swaps can reduce costs or help maintain production schedules when preferred parts are back-ordered. Known good alternatives are visible on an Octopart component page, which also shows pricing and inventory from distributors.

Case Study: Reflex CES

Reflex CES, a French manufacturer of long-lifecycle electronics, depends on accurate supply chain data to support decade-long production runs. Christophe Blaisius, Purchasing and Procurement Manager, shares: "Out of all the aggregator tools, I prefer Octopart. It’s more complete. It has more suppliers and more information available."

Using Octopart four to five times daily, Christophe checks stock, costs, packaging, and datasheets for informed decisions. With over 200 active suppliers, Reflex CES uses Octopart to streamline BOM analysis and identify alternatives when lead times are long. Features like historical stock tracking and lifecycle insights help Reflex CES manage availability and reduce risks.

Make Smart Procurement Decisions With Comprehensive Data

Avoid getting misled by low prices and hidden production costs. Make smarter decisions using Octopart’s comprehensive electronics supply chain data. Create a free account today and take control of your procurement process.