Trends in Flexible and Stretchable Electronic Components

New flexible and stretchable electronic components are the (very flexible) backbone of new devices that bend, flex and reshape the limits of design. Once confined to research labs and experimental builds, these materials are driving a new generation of high-performance wearables, medical sensors, conformal automotive surfaces and shape-shifting consumer tech.

According to Polaris Market Research, the global flexible electronics market generated $29.7 billion in 2024 and is projected to grow to $79.5 billion by 2034. This represents a robust compound annual growth rate (CAGR) of 10.4%.

For engineers, flexible electronics introduce new design demands. Creating products that can stretch, twist or compress without compromising performance requires components built for real-world deformation. In this article, we explore the enabling technologies, from stretchable substrates to micro-scale LEDs, that are helping flexible electronics move from promising prototypes to production-ready systems.

Next-Gen Components Driving Flexible Electronics

Panasonic BEYOLEX™ Thermosetting Stretchable Film

BEYOLEX™ is a thermosetting polymer material designed for printed electronics that must bend, stretch and still perform reliably. Unlike traditional silicone-based stretchable substrates, BEYOLEX is non-silicone, which simplifies manufacturing and maintains performance under repeated flexing.

From a spec standpoint, it’s impressive: elongation over 200%, a dielectric constant of 2.8 at 10 GHz and heat resistance up to 302°C. It also delivers high optical transparency (>90%), making it suitable for optoelectronic applications. Designers of wearable tech and automotive interiors can use it as a foundational layer for circuits that need to withstand daily deformation. Panasonic’s BEYOLEX MUAS13111AA is on Octopart and can be sourced today through DigiKey and other distributors.

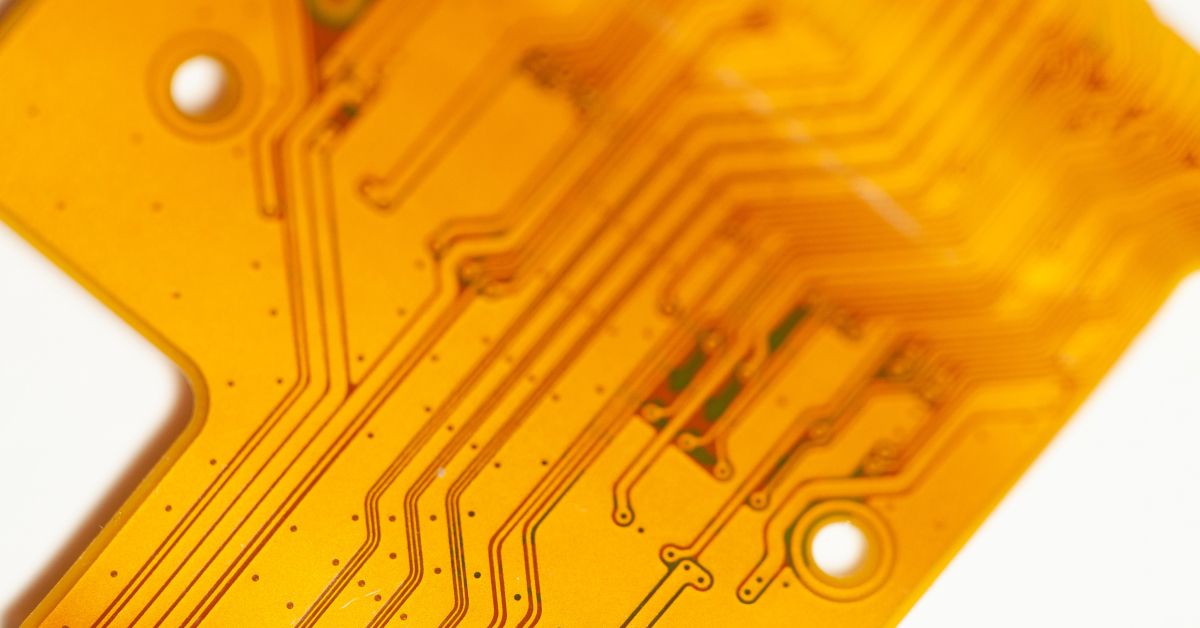

DuPont™ Pyralux® Flexible Circuit Materials

DuPont’s Pyralux® line offers a range of flexible copper-clad laminates and bonding materials designed for high-reliability flexible and rigid-flex circuits. These materials are known for their excellent thermal stability, chemical resistance and mechanical durability. The Pyralux® portfolio includes adhesive and adhesiveless constructions, providing designers with options to meet a range of performance requirements.

MicroLEDs for Flexible Displays

MicroLEDs are rapidly becoming a cornerstone of flexible display design, offering superior brightness, power efficiency and durability over OLEDs, especially in small form-factor devices. Suppliers like PlayNitride, AUO and Samsung offer MicroLED modules and chip-scale packages.

Because MicroLEDs don’t require a backlight or organic layers, they can be embedded in flexible substrates and shaped into novel form factors. Engineers working on AR/VR headsets, smart glasses and foldable devices are already building around MicroLED capabilities.

LG Display’s 12-Inch Stretchable Micro-LED Panel

LG Display’s 12-inch stretchable Micro-LED panel is still in the prototype stage, but it’s impressive enough to make our list. The display is capable of expanding up to 18 inches while maintaining 100 PPI resolution and full RGB color.

Built on a silicon substrate similar to contact lenses, this display features micro-LEDs around 40μm in size. Combined with a unique wiring design, it can survive over 10,000 stretch cycles. LG is positioning it for applications in wearables, automotive infotainment and signage. While sourcing isn’t possible yet, it’s a signal to engineers and buyers that flexible displays are crossing from hype into hardware.

Design Tips for Engineers Working with Flexible Materials

Designing flexible electronics calls for a fresh approach to layout, layering and material selection. Circuits must maintain performance while flexing, stretching or twisting, so understanding how mechanical stress affects each element is essential from the start.

- Substrate First: Start with the right foundation. Materials like TPU and polyimide flex differently under thermal cycling, which affects layout choices.

- Rethink Routing: Use arcs or serpentine traces instead of straight lines to prevent cracking under strain.

- Mind the Stack-Up: Flexible circuits require unique layering strategies, especially when mixing rigid and elastomeric components.

- Plan for Encapsulation: Soft electronics often need protective coatings that don’t interfere with movement or performance.

A little foresight during layout and materials selection can dramatically improve real-world durability and save a lot of debugging down the line.

From Prototyping to Production: What Changes in the BOM?

Early-stage development in flexible electronics often involves prototyping with materials that won’t scale well. Engineers may use lab-available conductive inks, off-the-shelf batteries or flexible PCBs with lower-grade adhesive layers. These options are all great for proving a concept, but aren’t ready for production environments.

As products move closer to production, BOMs must adapt. This may include shifting to pre-certified biocompatible substrates, selecting connectors rated for dynamic flex cycles or choosing encapsulants that resist delamination. Procurement teams need to be looped in early to identify supply chain constraints and vet materials with scalable lead times. Octopart’s free BOM Tool can help.

Sourcing Considerations in a Flexible World

As component capabilities stretch, so do the demands on sourcing strategies. For engineers, the challenge is integrating materials that deliver both mechanical flexibility and electrical performance. For sourcing professionals, it’s ensuring that those materials are available in scalable, certifiable and cost-effective ways.

Lead times, part number consistency and supplier reliability matter more than ever, so starting with Octopart is a smart way to begin. Some of the newer materials in this space are only recently entering distribution channels, so coordination with manufacturers and reps may be required.

Materials Powering the Flexible Revolution

Beyond the foundational components already covered, a wave of new materials, products and form factors is shaping what flexible electronics can do.

- Conductive Elastomers: Suppliers such as DuPont and Henkel offer conductive elastomers that enable designers to create skin-safe, deformable circuits with robust mechanical properties.

- Flexible Cables and Wiring Solutions: Transmitting power and data in flexible electronics necessitates cables that can adapt to dynamic movements and conform to various shapes. LOOMIA offers 4-wire flexible cables designed for high-motion areas and irregular shapes, ideal for applications in soft wearables and medical devices. Additionally, Molex provides flexible printed circuits (FPCs) and associated cables that offer advantages in size, weight and flexibility for medical and other wearable devices where comfort and unobtrusiveness are paramount.

- Advanced Stretchable Sensors: Stretchable sensors, like those from Interlink Electronics and StretchSense, are being integrated into motion capture wearables, health monitoring devices and soft robotics. Recent innovations include highly sensitive pressure sensors that can track muscle movement and neural signals with precision. Designed for integration into flexible substrates, stretchable sensors allow wearable devices to move with the body without sacrificing performance or reliability.

- Soft and Flexible Batteries: Researchers at Linköping University have developed batteries that use fluid electrodes rather than solid ones. This allows batteries to bend, twist and stretch without sacrificing energy storage capacity. Such batteries could soon power future wearable technology.

- Integration of AI with Flexible Electronics: AI is enabling the creation of wearable devices that can analyze data and provide personalized feedback. For instance, wearable devices that track physical activity can use AI to provide personalized exercise plans and track progress over time.

Start Flexing Now

Flexible and stretchable components are shaping the next wave of electronics innovation, yet working with them requires a fresh approach to system design and sourcing. Whether you’re building next-gen wearables or industrial robotics, the materials and components we’ve explored here enable you to build products that move, adapt and perform with precision under dynamic conditions.

Design with intention. Source with confidence. Stay flexible.