Understanding Systems Engineering

In previous articles, we have discussed the importance of requirements management in engineering projects and the necessity of designing products with manufacturability in mind. It is essential to recognize that the design of an electronic product involves not only electronic design tasks but also a series of activities spanning multiple disciplines, such as mechanical design, firmware and software development, programmable logic design, simulations, and other areas like project management, marketing, and sales.

In this article, we will navigate through the various areas involved in an engineering project and the different stages of electronic product development from a project execution standpoint. This includes the initiation phase, as well as the planning, following up, design and development, validation, testing, and certification phases, among others.

Electronics Product Development: What Is Systems Engineering?

Systems engineering is a structured, interdisciplinary approach to developing complex products that require coordination across multiple technical and non-technical domains. In the context of electronic product development, it ensures that hardware, software, mechanical design, firmware, compliance, and even business processes work together cohesively. It emphasizes clear requirements, defined development phases, robust integration strategies, and lifecycle management to deliver reliable, manufacturable, and market-ready products. By applying systems engineering, teams can align technical efforts with business goals and reduce costly late-stage issues.

Below is a list of the key roles in a product development project and their primary functions.

Project Management

Responsible for project planning (roadmap, milestones), coordinating tasks across departments, resource and configuration management, project tracking, and reporting progress or delays to leadership.

Product Management

This area defines product requirements and functionality, collaborates with sales and marketing on product benchmarking (price, features, design), and aligns the design with business and marketing strategies. It also ensures the final product meets strategic objectives.

Marketing and Sales

Any product intended for commercialization requires market research and positioning. This department handles pricing strategies, sales channels, and launch campaigns.

Hardware Engineering

The hardware team defines the system architecture (CPU, memory, sensors, connectivity, etc.), selects electronic components (in collaboration with supply chain and production engineers), designs schematics and PCB layouts, performs signal and power integrity simulations, and supports validation and certification testing.

Software Engineering

In electronic product development projects, there's typically a low-level software development (which includes bootloaders, low-level drivers, etc.) and a high-level software development component (like the operating system, applications, and scripts). This work falls under the software development department, although it's common for the embedded software and high-level software areas to be quite distinct.

Mechanical/Industrial Design

Mechanical or industrial design engineers design the product enclosure, select materials and finishes, analyze compatibility with electronics (mechanical interferences, connector placement, buttons, etc.), ergonomics, and thermal management (heat dissipation for processors, batteries).

Quality and Compliance

For a product to be released to the market, it must comply with mandatory standards and regulations, such as CE marking, FCC regulations, RoHS, etc. Furthermore, environmental tests (temperature, humidity, vibrations), impact tests, IPx assessments, and specific certifications (Wi-Fi, Bluetooth) must be carried out. Quality and Homologation department is responsible for all these activities, as well as the quality controls for materials, processes, and the final product.

Manufacturing/Production Engineering

Once the product has completed all design and validation phases, it's time for manufacturing. This is the responsibility of the production department, which handles not only the manufacturing itself but also the design of all necessary processes for fabrication, assembly, testing, and more.

Supply Chain

A no less critical task is supply chain management, which encompasses supplier management and qualification, the procurement of all necessary manufacturing components, supply risk analysis, component obsolescence control (lifecycle management), inventory management, and purchase planning. All these activities are handled by the Supply Chain department.

What Are the Phases of an Electronic Product Development Project?

As we mentioned in the introduction, an electronic product development project is a process that involves different areas, each with specific tasks. Therefore, the project is divided into distinct phases to break down high-level tasks into smaller, manageable ones. These smaller tasks are then executed by various work teams, ensuring timely completion and quality.

An engineering project should, at a minimum, be divided into the following phases:

- Definition and Kick-Off Meeting (KOM)

- Planning

- Design

- Prototyping

- Validation

- Industrialization

- Launch

1. Definition of the Product

During this initial phase, the fundamental questions are: What purpose does the product serve, and what real need does it address? If there aren't solid answers to these questions, initiating the project might not be worthwhile. Otherwise, following an in-depth analysis (including identifying needs, competitors, necessary resources, development timelines, and product development costs) a Kick-off Meeting (KOM) is convened. Here, the project is officially presented, along with the project team, scope, key dates (start, end, and intermediate milestones), cost estimations, the target customer, or the specific need the product fulfills. This meeting officially marks the project's launch.

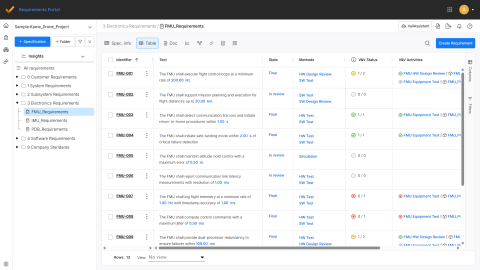

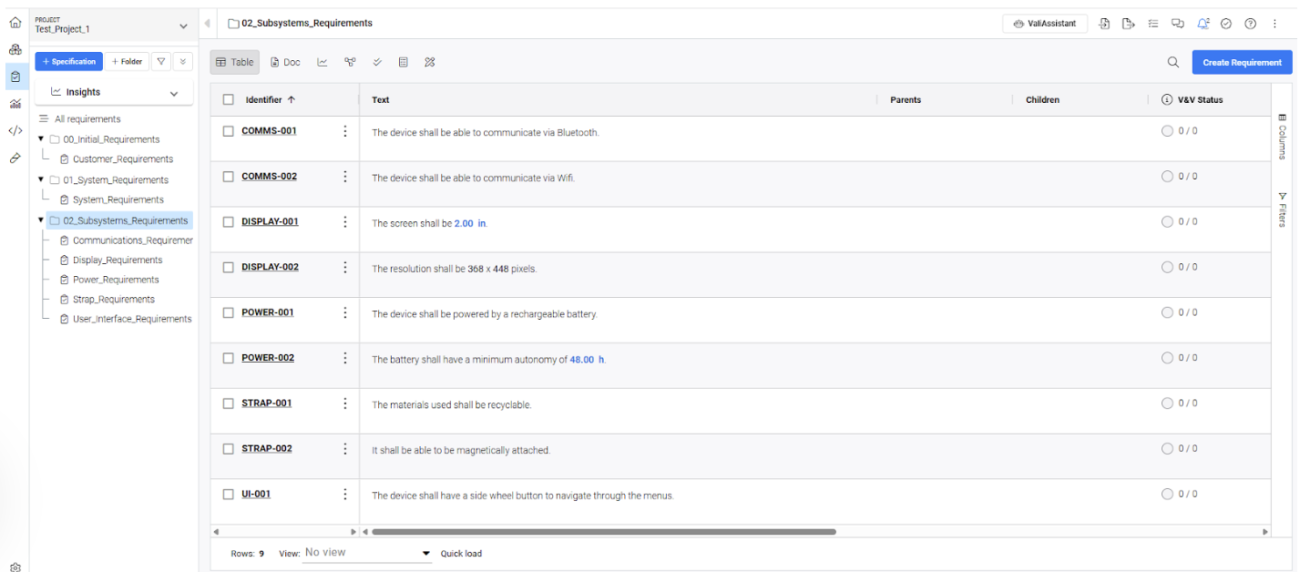

The subsequent and arguably most crucial step is the definition of project requirements. All defined requirements will collectively form the product specification, which will serve as the foundational document for the product's development.

2. Project Planning

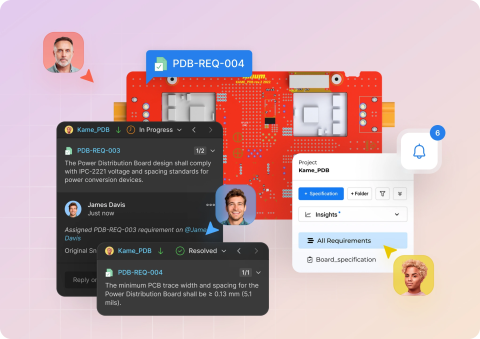

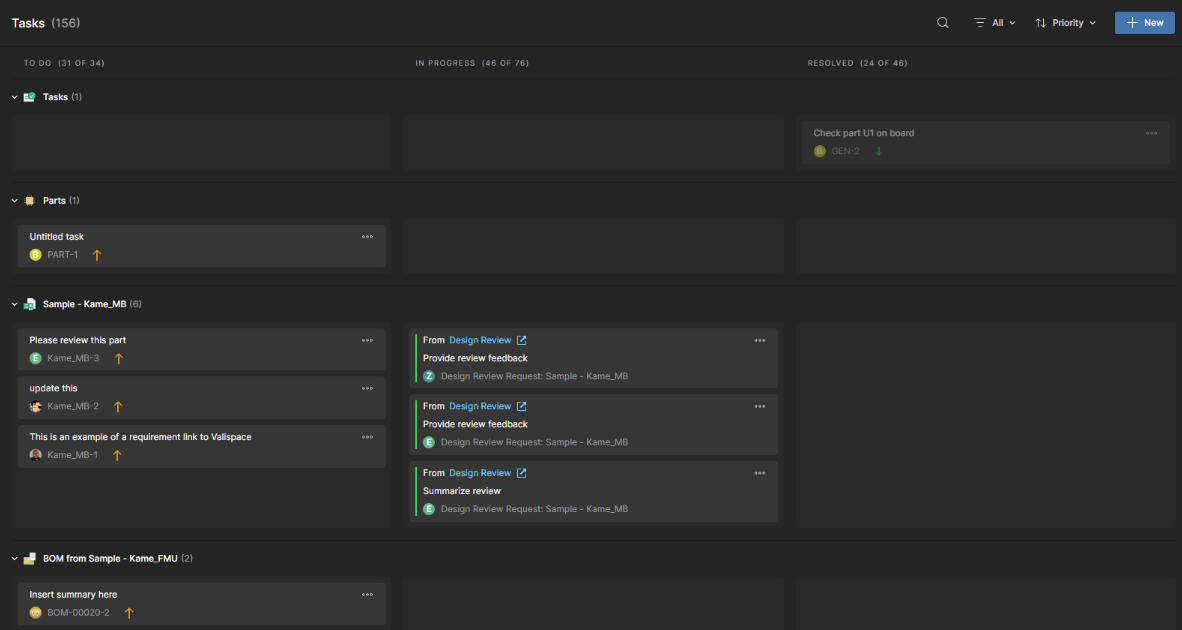

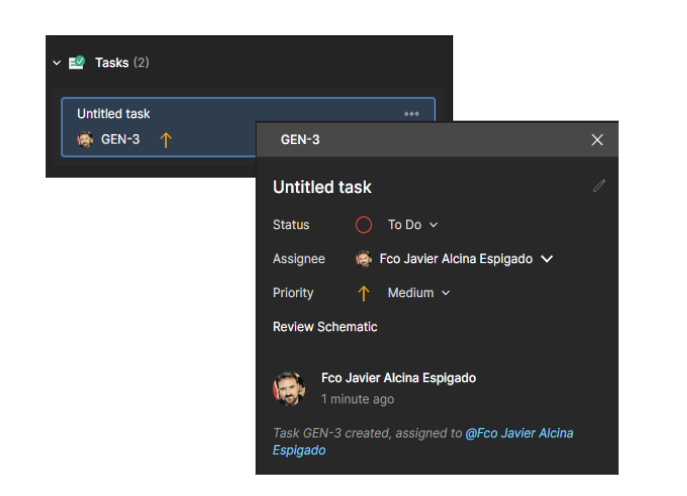

Project planning is crucial for execution, ensuring all involved parties are aware of development timelines and key milestones. More importantly, it highlights dependencies across disciplines, especially when integrating hardware with firmware or mechanical components. Projects often leverage agile or waterfall methodologies for planning. Altium Develop offers a task management tool (similar to a Kanban board) that can be linked directly to schematics and layouts. This streamlines the workflow and eliminates the need for external tools.

3. Product Design

When we talk about design, we're not just referring to the hardware design itself, but to the design of all integrated parts or disciplines that come together to conceive the product. This includes hardware, mechanical design, thermal design, firmware, and software.

Any design process begins with an initial conceptual design – a diagram representing the overall architecture of the product to be created. This diagram serves not only to structure the design but also allows for the division of more specialized tasks, such as "PCB antenna design for BLE circuit" or "power supply design." Once the architecture is clear, the team moves on to detailed design. This involves creating schematics, selecting components, running simulations, writing code, designing PCBs, conducting thermal analyses, and performing signal and power integrity simulations.

Should any deficiencies be found during these simulations, the design process is iterated until the simulations yield positive results.

4. Prototyping and Integration

The next step is to build an initial prototype that involves all technical areas:

- PCB / PCBA (Printed Circuit Board / Printed Circuit Board Assembly)

- Enclosure 3D Print

- Firmware / Software release

Once a version of each component is ready, it's time to integrate everything and form the first functional prototype.

5. Testing and Validation

Once the prototype is functional and has undergone an initial basic verification, the validation team executes a comprehensive suite of tests and evaluations to validate its correct operation. Proper test definition involves linking each test to specific requirements, ensuring that every requirement has one or more associated tests for verification and validation. This validation extends beyond mere functionality, encompassing other aspects such as electrical testing, thermal assessments, signal integrity tests, electromagnetic compatibility (EMC) tests, mechanical stress, and enclosure durability.

6. Industrialization Phase

If validation is successful and no redesigns are necessary, it's time to industrialize the product, meaning transforming it into a mass-producible item. It's crucial that Design for Manufacturability (DFM) requirements were considered during the design phase to avoid unexpected surprises that might necessitate a product redesign due to manufacturing issues.

Additionally, the production processes involved in manufacturing the product must be validated. This involves verifying their reliability over a large production run. Typically, a significant sample of 500 to 1000 units is manufactured and subjected to comprehensive validation, with the results of each manufactured piece reviewed and every process validated.

This phase is also when all necessary certifications are obtained (keeping in mind that regulations vary by country or region), and supply agreements with component vendors are finalized.

7. Product Launch

The launch of a product isn't simply about manufacturing it and shipping it to the customer. A successful launch involves a series of critical steps that can determine its ultimate success or failure, even for a well-designed product.

It's crucial to plan the launch meticulously, maintain robust quality control over manufactured parts, establish effective sales channels, manage warranty returns, provide excellent customer service and technical support, correctly handle future updates, and be environmentally conscious regarding the product's logistics (packaging, transportation, and recycling).

Conclusions

- Electronic product development involves numerous stakeholders

In electronic product development, hardware design engineers are not the only pieces of the puzzle. The team involved typically includes at least electronic engineers, industrial designers, firmware/software developers, simulation specialists, production teams, quality assurance, sales, logistics, and planning departments.

- Electronic product development requires multiple phases

Developing an electronic product necessitates a series of sequential steps, beginning with requirements definition and progressing through design, prototyping, validation testing, and industrialization, culminating in the product's market launch.

Fortunately, you're not alone in this entire process. Explore how Altium Develop can support you throughout your product development journey.