The Hidden Dangers of Alternate Parts (And How to Avoid Them)

At some point in every product lifecycle, engineers face an inevitable dilemma: stick with that EOL (End-of-Life) part and risk future manufacturing issues, or replace it with something newer and potentially introduce compatibility problems?

Even what appears to be a straightforward substitution can lead to costly mistakes. The key to navigating these decisions successfully is ensuring you have access to accurate, current component data.

The Obsolete Package Trap

The industry has adhered to the proven FFF approach for decades: Form, Fit, Function. Match the package first, verify the pinout, then validate performance and functionality.

The method worked well until the late 2000s, when Western manufacturers found themselves struggling against the cost advantages and production volumes of their Eastern counterparts. With silicon die processes already highly optimized, innovation shifted to packaging – driven largely by the relentless push for miniaturization.

The evolution in packaging has made the traditional "match-the-package-first" approach increasingly problematic. When evaluating legacy components, I find it useful to ask, "Would any major Western manufacturer still bother producing this today?" If the answer is no, you're probably looking at a candidate for modernization – often because the package itself has become obsolete and was likely the primary reason the component was discontinued in the first place.

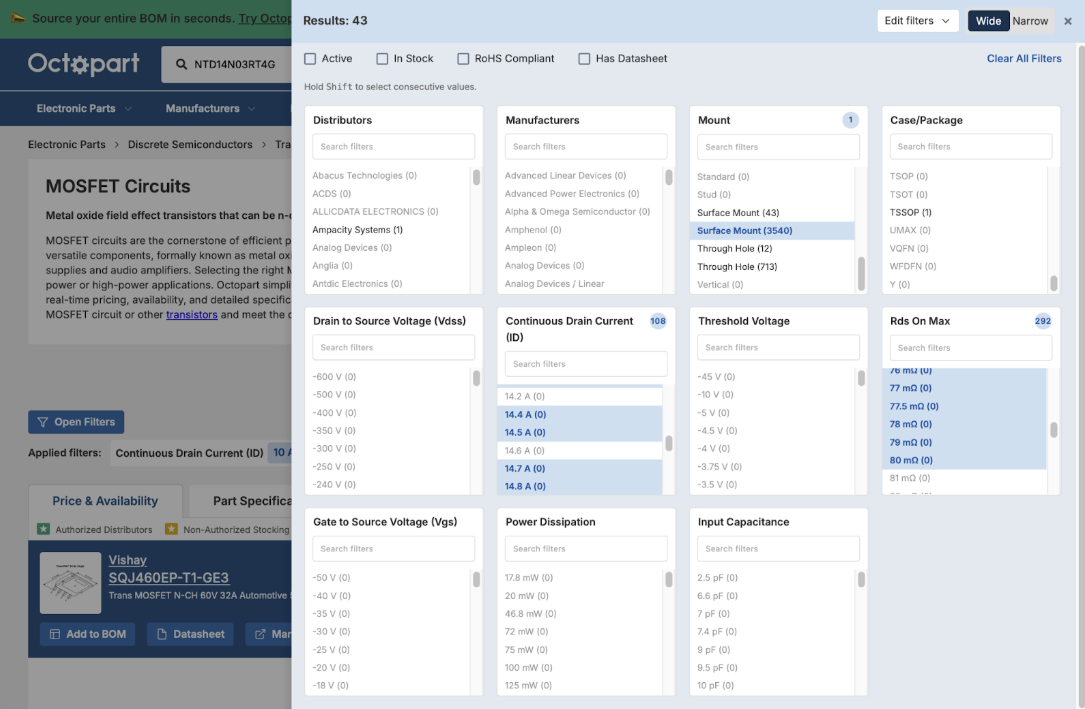

Searching widely across manufacturers and suppliers is necessary to find the right replacement. Advanced parametric search tools like Octopart’s make this process manageable, letting you quickly filter through hundreds of options. Their recent improvements to search and filtering capabilities have further cemented Octopart as the industry-leading platform for component research.

The EOL-to-EOL Mistake

Perhaps the most frustrating pitfall in component substitution is inadvertently replacing an EOL part with another component that's already flagged as Not Recommended for New Designs (NRND) or approaching its own end-of-life.

Such a mistake creates a costly cycle where, as soon as you complete the replacement's qualification, you find yourself back at the beginning, searching for yet another substitute. The qualification time and costs multiply, and production schedules suffer.

To break the cycle, teams need visibility into component lifecycle status across multiple sources. Octopart addresses this need by aggregating lifecycle data from both manufacturers and distributors, providing a more complete picture than single-source providers. The comprehensive view helps you spot potential issues before they derail your project timeline.

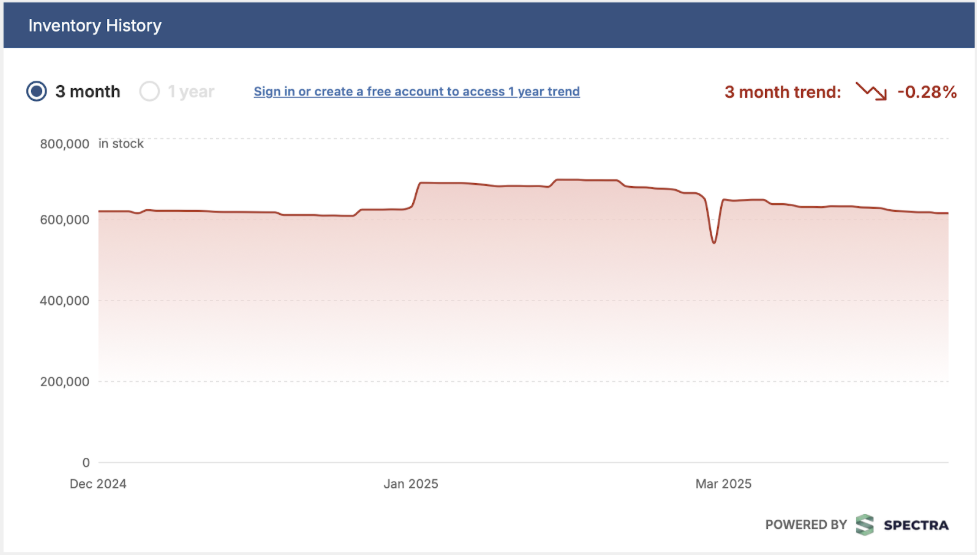

Beyond current status, Octopart's Inventory History feature provides valuable insight into supply chain trends. The tool displays historical stock levels across all distributors, letting you intuitively understand patterns over time. A component showing consistent inventory declines across multiple suppliers often signals an impending lifecycle change, even before official EOL announcements. Early-indicator data can help you stay ahead of obsolescence issues rather than react to them.

Conclusion

Successful component substitution goes beyond simple technical matching. It requires understanding market trends, lifecycle status, and supply chain dynamics. The hidden dangers are real, but they're manageable with the right approach and tools.

Octopart streamlines the process by consolidating comprehensive component data, up-to-date availability, and intelligent alternates in one platform. The time saved on research translates directly to faster design cycles and more reliable product launches. Create a free account today and take control of your procurement process.