Cost Optimization Strategies for Industrial Electronics BOMs

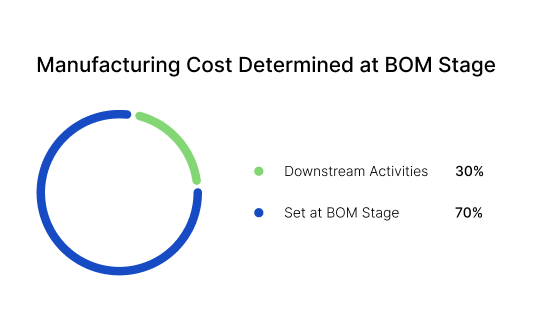

Did you know that as much as 70% of a product’s total manufacturing cost is determined at the Bill of Materials (BOM) stage? This means that the decisions you make early, long before production begins, have a profound impact on profitability, lead times, and overall supply chain resilience. For industrial electronics, where complexity and precision are non-negotiable, every single component choice, from microcontrollers and power modules to connectors and passive elements, can either strengthen your competitive edge or erode your margins.

Key Takeaways

- BOM decisions set up to 70% of manufacturing costs. Early, strategic choices are the foundation for profitability, agility, and resilience.

- Component standardization, digital transformation, and lifecycle intelligence are essential for controlling costs and avoiding supply chain disruptions.

- Supplier partnerships, value engineering, and advanced analytics unlock ongoing savings and risk mitigation.

- Altium Develop empower teams to build future-ready, cost-optimized BOMs with up-to-date data and real-time collaboration.

We live in a time when component shortages, price fluctuations, and geopolitical risks are the norm, and controlling BOM is a survival strategy. Yet, despite its importance, many engineering and procurement teams continue to face recurring challenges: hidden inefficiencies, fragmented sourcing strategies, and outdated BOM management practices. These issues often lead to unexpected cost overruns, supply chain bottlenecks, and even costly redesign cycles that delay time-to-market.

The good news? With the right combination of strategic planning, process discipline, and digital tools, these challenges can be turned into opportunities for cost savings. Altium Develop empowers teams to make smarter, data-driven decisions at every stage of the design-to-production lifecycle. By leveraging the right tools, organizations can simplify component selection, improve sourcing visibility, and build BOMs that are both cost-efficient and resilient.

Standardize and Consolidate Components

Component standardization is one of the most powerful levers for cost optimization. By reducing the variety of parts used across multiple product lines, companies can achieve cost reductions of 15-20%, simplify inventory management, and significantly increase purchasing leverage with suppliers. Standardization also minimizes engineering complexity, reduces qualification cycles, and lowers the risk of obsolescence.

A significant share of BOM costs stems from preventable inefficiencies, like redundant part numbers and fragmented supplier relationships. By standardizing components and consolidating suppliers, companies can unlock annual savings without compromising quality or performance.

Take a company producing industrial controllers. Initially, they are using many different capacitor types across three product lines. This diversity creates unnecessary complexity in procurement and inventory management. By rationalizing their design and standardizing down to just a small number of capacitor types, they achieve an 20-30% reduction in procurement costs, improved supply chain resilience, and simplified their quality assurance processes. The result? Lower costs, faster sourcing, and a more agile production environment.

This is where Altium Develop comes into play. Its capabilities provide up-to-date visibility into component availability, pricing, and lifecycle status. Teams can track, compare, and standardize components across multiple projects. With built-in analytics and supplier integration, engineers can quickly identify consolidation opportunities, avoid high-risk parts, and ensure that every BOM is optimized for both cost and reliability.

Design for Sourcing (DFS) and Lifecycle Awareness

When it comes to BOM cost control, design decisions are sourcing decisions. Poor sourcing practices, such as selecting components without considering availability, lifecycle status, or supplier diversity, can increase BOM costs. These costs often arise from component shortages, end-of-life (EOL) surprises, and lack of visibility into the supply chain. Ignoring sourcing considerations during the design phase can lead to production delays, expensive redesigns, and even product launch failures.

Design for Sourcing (DFS) is about proactively integrating procurement intelligence into the design process. Engineers and sourcing teams should collaborate early to ensure that every component selected is not only technically suitable but also commercially viable and future-proof. Lifecycle awareness, knowing whether a part is in active production, approaching obsolescence, or already discontinued, is critical to avoiding last-minute crises.

Consider a team designing a new industrial sensor. They select a custom connector because it offers a slight performance advantage. Months later, the connector became unavailable due to a supplier discontinuation. The result? A full PCB redesign, costing up to $100,000 in rework, plus weeks of lost time. In future projects, the team switch to standard, widely available connectors with multiple sourcing options. This simple change eliminates the risk of single-source dependency and significantly improves design flexibility.

Altium Develop provides the tools needed to make DFS and lifecycle awareness a reality. With the latest lifecycle status, alternate part suggestions, and integrated supplier data, teams can avoid EOL components and make cost-conscious choices from the start. Engineers can see availability, pricing, and risk indicators directly within their design environment, ensuring that every decision supports both technical and business objectives.

Use Cross-References and Alternate Parts

Given the current level of supply chain volatility, approved alternates are your insurance policy. Maintaining validated alternates for critical components can prevent urgent last-time buys, grey-market sourcing, and production stoppages. When a part goes obsolete or becomes scarce, the cost impact can be severe. BOM costs can spike by 3-5x due to urgency and scarcity premiums. By planning for alternates upfront, companies can avoid panic-driven decisions and maintain production continuity.

Imagine an industrial engineering team leverages Altium Develop BOM Management capabilities to automatically flag EOL parts and suggest alternates during the design phase. When a key microcontroller is suddenly discontinued, they can swap to a validated alternate within hours, avoiding weeks of redesign and thousands of dollars in expedited shipping. This capability turns what could have been a major disruption into a minor adjustment.

Altium Develop tools offer cross-referencing abilities and alternate part management. These features ensure that every BOM includes approved alternates, reducing risk without sacrificing reliability. Teams can maintain compliance, improve sourcing flexibility, and achieve cost savings while keeping projects on schedule.

Negotiate Tiered and Contract Pricing

Strategic supplier partnerships and volume-based pricing agreements are essential for cost optimization. By consolidating demand across SKUs and negotiating tiered pricing or annual contracts, companies can achieve cost improvements while also enhancing resilience against supply disruptions. These agreements provide predictable pricing and priority allocation during shortages.

Take an industrial manufacturer that negotiates annual volume agreements with preferred suppliers, locking in favourable pricing for high-demand components. This strategy reduces unit costs and ensures supply continuity during peak demand periods. By leveraging consolidated purchasing power, they not only save money but also strengthen their supply chain resilience.

Altium Develop BOM management features make it easy to track supplier quotes, compare pricing tiers, and manage contract terms. These capabilities support smarter negotiations and better cost control, ensuring that engineering and procurement teams work from a single source of truth.

Embrace Digital BOM Management and Data Standardization

Inconsistent data is one of the most overlooked cost drivers in BOM management. Studies show employees spend approximately 9 hours per week searching for information, and data teams can lose up half of their time to finding and preparing data. Now imagine how how much time procurement teams waste every week reconciling mismatched or incomplete component information. This inefficiency slows down decision-making and introduces errors that can lead to production delays and inflated costs.

Modern digital BOM management solutions eliminate these pain points by introducing intelligent data standardization and centralized control. When all stakeholders (engineering, procurement, and manufacturing) work from a single source of truth, the result is faster collaboration, fewer errors, and more accurate cost forecasting. Accurate decision-making starts with unified data structures, and without them, even the most advanced sourcing strategies can fail.

Consider an industrial manufacturer dealing with legacy systems, facing chronic spreadsheet errors that cause thousands of dollars in weekly losses due to incorrect inventory levels. By introducing automated validation checks and machine learning-powered error detection, they can reduce spreadsheet errors by more than 90%. These tools will flag inconsistencies in real time, preventing costly mistakes before they reach the production floor. The result is a fully digitized, error-resistant BOM process that saves both time and money.

Altium Develop provides a powerful digital infrastructure for BOM management. Features like automated validation and the latest dashboards ensure that all teams work with accurate, standardized data. You can reduces errors but also enhance collaboration across engineering and procurement, creating a seamless workflow from design to sourcing.

Value Engineering and Lifecycle Cost Modelling

Value engineering is a structured methodology for maximizing value without compromising performance. By analyzing the function of each component and exploring alternatives, companies can identify opportunities to achieve the same or better performance at a lower cost.

Lifecycle cost modelling takes this a step further by considering total ownership costs, including maintenance, energy consumption, and disposal. Unlike simple unit price comparisons, lifecycle modelling provides a long-term perspective, ensuring that cost decisions made today don’t create hidden expenses tomorrow.

Picture an industrial engineering team using predictive modelling to forecast material price trends with high accuracy (over 90%). This insight allows them to make smarter decisions about when to buy, when to hold, and when to sell surplus stock. By turning idle inventory into revenue streams, they reduce waste but also improve cash flow; a win-win for both operations and finance.

Altium Develop enables cost modelling, lifecycle analysis, and value engineering workflows, giving teams the tools to make data-driven sourcing decisions. With integrated analytics, engineers can evaluate trade-offs between cost, performance, and lifecycle impact, ensuring that every component choice supports long-term business objectives.

Continuous Improvement and Strategic Supplier Relationships

BOM optimization is an ongoing process. Companies that embrace a culture of continuous improvement consistently outperform their peers in cost control and supply chain resilience. Regularly reviewing BOMs, updating alternates, and monitoring supplier performance helps identify new cost-saving opportunities and address emerging risks before they escalate.

Many industrial engineering teams deploy up-to-date dashboards to monitor inventory levels, supplier lead times, and stock trends. Such transparency allows them to avoid costly production stoppages and respond quickly to market fluctuations. The result is a more agile and resilient supply chain.

Altium Develop collaborative environment supports continuous improvement by enabling cross-functional teamwork and strategic supplier relationship management. With shared dashboards and integrated analytics, teams can track performance metrics, identify trends, and implement improvements.

Risk Assessment and Mitigation

Every BOM carries inherent risks, whether it’s supply chain disruptions, component obsolescence, or market price volatility. Identifying and mitigating these risks early is essential to maintaining cost stability and production continuity. A proactive risk management strategy can prevent emergency measures like last-minute air freight, which can multiply costs by 4x or more.

While leading the supply chain for a manufacturer site I worked at, we mapped component lifecycles against production schedules, creating buffer systems for critical parts without inflating inventory costs. This proactive approach reduced emergency air freight expenses by 400% (moving many items from air to sea freight), while ensuring uninterrupted production during global supply chain disruptions.

Altium Develop helps monitor market trends and manage price fluctuations. By leveraging predictive analytics, industrial engineering teams can lock in favourable pricing agreements ahead of anticipated shortages and ensure cost stability even during volatile periods.

Total Cost of Ownership (TCO) and Life-Cycle Cost Analysis (LCCA)

Unit price is only part of the story. Total Cost of Ownership (TCO) evaluates the long-term costs associated with components, including maintenance, energy consumption, and disposal. Similarly, Life-Cycle Cost Analysis (LCCA) examines the total cost of a product throughout its entire lifecycle, from design to end-of-life. These methodologies help companies identify hidden cost drivers and make smarter sourcing decisions that optimize value over time.

For example, an engineering team can analyze the energy consumption and disposal costs for key components in a robotic arm. By selecting options that minimize total lifecycle expenses, they can achieve both cost savings and sustainability goals, aligning with corporate ESG initiatives.

And here again, Altium Develop comes in handy. Access to up-to-date data enables TCO and LCCA analyses, supporting informed, strategic decisions that optimize costs across the entire product lifecycle.

Conclusion: Building Cost-Optimized Industrial Electronics BOMs

Cost optimization in industrial electronics BOMs is not only about reducing expenses but also about creating smarter, more resilient systems that balance quality, reliability, and financial objectives. Given global supply chain volatility and rapid technological change, the ability to manage BOM costs effectively is a strategic differentiator.

By focusing on component standardization, lifecycle awareness, alternate part strategies, strategic sourcing, digital BOM management, value engineering, continuous improvement, risk mitigation, and TCO/LCCA analysis, organizations can achieve cost savings, accelerate time-to-market, reduce operational risk, and strengthen competitive positioning.

The key is to embed these practices into the design and sourcing process from day one, ensuring that every decision is informed by accurate data and aligned with long-term business goals. Such proactive approach transforms BOM management from a reactive cost-control exercise into a strategic enabler of innovation and profitability.

Altium Develop provides the integrated tools and collaborative environment needed to make this vision a reality. With the latest data visibility, intelligent analytics, and seamless cross-functional workflows, your team can build BOMs that are not only cost-optimized but also future-ready.

Whether you need to build reliable power electronics or advanced digital systems, Altium Develop unites every discipline into one collaborative force. Free from silos. Free from limits. It’s where engineers, designers, and innovators work as one to create without constraints. Experience Altium Develop today!