How Does Sourcing Change for Rapid PCBA Prototyping?

The global PCBA market is projected to reach USD 90.91 billion by 2025, driven by the rapid growth of consumer electronics, automotive systems, and industrial automation. But within this booming sector, one segment is moving faster than the rest: rapid PCBA prototyping.

This article delves into how sourcing strategies must evolve when speed is the primary objective. Drawing from our experience and insights from Altium’s integrated tools, we will explore actionable approaches that help teams prototype faster, smarter, and with greater resilience. From up-to-date BOM management to automated RFQs and supplier collaboration, we will show how digital transformation is reshaping the prototyping landscape.

What Is Rapid PCBA Prototyping?

Rapid PCBA prototyping refers to the accelerated design, sourcing, assembly, and testing of printed circuit board assemblies, typically in very low volumes, often between 1 and 100 units. These prototypes serve a variety of critical functions, including:

- Validating new designs before committing to full-scale production.

- Testing functionality and performance under real-world conditions.

- Iterating quickly based on engineering feedback or stakeholder input.

- Preparing for pilot production, investor presentations, or customer demos.

Unlike traditional production runs, which prioritize cost-efficiency and scalability, rapid prototyping is all about speed. The goal is to get a working board in hand as quickly as possible, even if that means paying a premium for components, expedited services, or specialized vendors. In many cases, the cost of delay far outweighs the cost of fast-tracked sourcing.

How Sourcing Changes in Rapid Prototyping

Sourcing for rapid prototyping is fundamentally different from sourcing for production. Here is how:

1. Speed Trumps Cost

In production environments, sourcing teams focus on cost optimization, negotiating volume discounts, comparing suppliers, and planning months in advance. In prototyping, however, the priority is immediate availability. If a component is in stock and can ship today, it is the right choice, even if it costs more.

Our data shows that teams often pay 20-30% more per component during prototyping, and that is considered acceptable. The opportunity cost of waiting, whether it is a missed investor pitch or a delayed product launch, is usually far greater than the premium paid for expedited parts.

2. BOMs Are Fluid

In prototyping, the Bill of Materials (BOM) is rarely static. Engineers frequently swap components mid-cycle due to availability issues, performance tweaks, or last-minute design changes. This dynamic nature demands a sourcing process that is both flexible and responsive.

Our vendors often refer to prototyping BOMs as “living documents.” That is why we advocate for digital BOM tools like those in Altium that support the latest updates, version control, and integrated supply chain data. These tools allow engineering and procurement teams to stay aligned, even as designs evolve.

3. Supplier Relationships Are Different

In production, companies typically cultivate long-term relationships with a few strategic suppliers. In prototyping, the sourcing strategy is more opportunistic. Teams often engage with multiple distributors, including niche or specialty vendors, to secure parts quickly.

Clear communication becomes essential. When suppliers understand that an order is for a prototype, they often prioritize it differently, offering faster turnaround times or more flexible terms. Altium’s RFQ automation tools streamline this process, enabling teams to solicit and compare bids rapidly, even across diverse supplier networks.

Key Sourcing Challenges in Rapid Prototyping

1. Component Availability

The biggest challenge in rapid prototyping is finding components that are in stock. Lead times of 8–12 weeks are common for many ICs (integrated circuits), which is unacceptable for a prototype needed in 5 days.

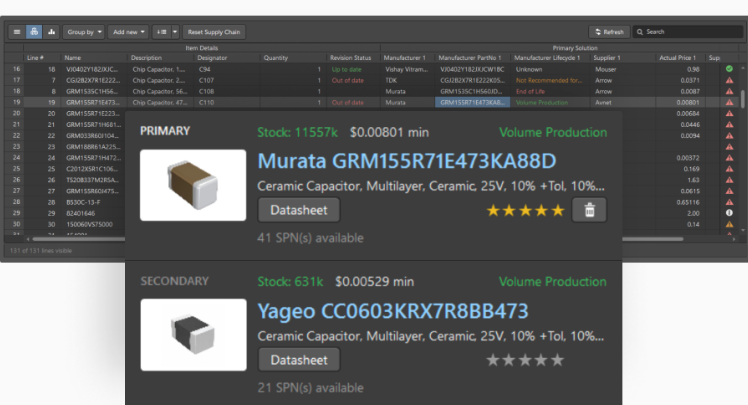

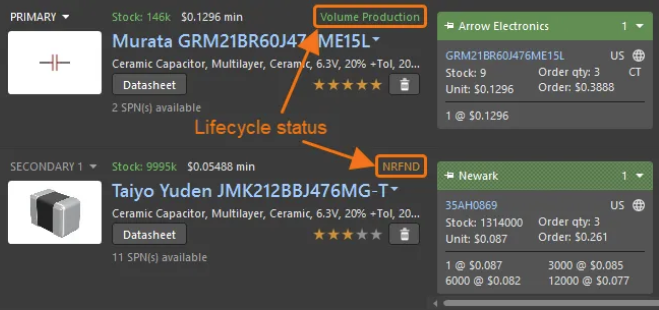

Altium’s solutions address this by integrating the latest distributor data directly into the design environment. Engineers can see:

- Which parts are in stock

- How many units are available

- Lead times and pricing

- Lifecycle status (active, obsolete, NRND)

2. Obsolescence and Lifecycle Risk

Because prototypes often use innovative or niche components, there’s a higher risk of sourcing parts that are obsolete or nearing end-of-life (EOL). That's why lifecycle visibility is critical. In Altium, designers are alerted when a part is obsolete or not recommended for new designs (NRND) and are offered alternatives, which saves teams from multiple sourcing crises. Examples can include where a key microcontroller went EOL just days before a prototype run.

3. Fragmented Supply Chains

Rapid prototyping often involves sourcing from multiple vendors, each with different shipping times, documentation standards, and pricing models. This fragmentation increases the risk of delays and errors.

The answer is consolidated BOMs with sourcing data embedded directly into them. Consider using platforms platforms that aggregate sourcing data and streamline procurement into a single, efficient process.

Actionable Strategies for Faster, Smarter Sourcing

Accelerating PCBA prototyping is not just about working harder. It is about working smarter. Here are five proven strategies that teams can implement to streamline sourcing, reduce delays, and improve prototype outcomes.

1. Design for Availability

Start your design process with components that are not only technically suitable but also readily available. In Altium, engineers can filter parts by stock status, regional availability, and lifecycle stage, all within the design environment. This proactive approach minimizes last-minute BOM changes and procurement bottlenecks.

Takeaway: Choose components that are available now and not just ideal on paper. Availability-aware design is one of the fastest ways to accelerate prototyping.

2. Use Digital BOM Tools

Traditional spreadsheets are too slow and error-prone for the pace of rapid prototyping. Instead, use digital BOM tools that support:

- The latest updates

- Version control

- Embedded sourcing data

- Cross-functional collaboration

Altium integrations connect BOMs directly to live distributor feeds, ensuring that sourcing teams always have access to the most current pricing and availability data. Additionally, Altium’s commenting and versioning features allow engineers and procurement teams to collaborate seamlessly, reducing miscommunication and speeding up decision-making.

Takeaway: A live BOM is a fast BOM. The latest data and real-time collaboration tools eliminate guesswork and keep teams aligned.

3. Build a Preferred Parts Library

Creating a curated library of pre-vetted, readily available components can dramatically reduce sourcing time and improve consistency across projects. These libraries typically include parts with:

- Short lead times

- Stable supply chains

- Proven compatibility with prototype designs

Altium supports centralized component libraries, allowing teams to share preferred parts across projects and locations. This not only speeds up sourcing but also improves design reuse and quality control.

Takeaway: Standardize where you can to move faster where you can’t. A well-maintained parts library is a strategic asset.

4. Partner with Prototype-Friendly Suppliers

Not all suppliers are equipped to support rapid prototyping. Look for partners who:

- Accept small quantity orders

- Offer fast shipping (same-day or next-day)

- Provide responsive customer support

- Understand the unique needs of prototyping teams

When we speak with suppliers, they often say, "We love working with teams who are clear about their timelines." Transparency helps suppliers prioritize your order and offer tailored solutions.

Takeaway: Choose suppliers who move at your speed. The right partner can shave days off your timeline.

5. Plan for Substitutions

Even with meticulous planning, components can go out of stock mid-cycle. That’s why it is essential to have a substitution strategy in place:

- Identify alternates during the design phase.

- Use parametric filters to find drop-in replacements.

- Document acceptable substitutes directly in the BOM.

Altium simplifies this process by suggesting alternatives based on electrical and mechanical parameters. Teams can pre-approve substitutes, reducing the need for emergency redesigns and avoiding delays.

Takeaway: Always have a backup plan. Substitution readiness is a key part of sourcing agility.

The Role of Altium’s Solutions in Rapid Prototyping

Altium’s ecosystem is purpose-built to support the speed, flexibility, and precision required in rapid PCBA prototyping. Here’s how its core capabilities empower teams to move faster without sacrificing quality:

- Up-Yo-Date Component Data: Access the latest stock levels, pricing, and lifecycle status from major global distributors directly within the design environment. Ensure that sourcing decisions are based on current, actionable data.

- Integrated BOM Management: Create, manage, and share BOMs with embedded sourcing data. Altium’s BOM tools support version control, the latest updates, and collaborative workflows across engineering and procurement teams.

- Design-to-Procurement Workflow: Transition seamlessly from schematic to sourcing to manufacturing. Altium enables instant quoting and direct order placement with trusted manufacturers.

- Collaboration Tools: Share designs, BOMs, and sourcing data with internal teams, external manufacturers, and stakeholders, all in one secure, cloud-based environment.

Conclusion

Rapid PCBA prototyping has become a key advantage in meeting tighter schedules and higher product expectations. To keep pace, engineering and sourcing teams need tools that support fast iteration, flexible design changes, and close collaboration. Integrated solutions help shorten cycle times and get working prototypes built quickly. With the industry moving toward more automation, cloud-based workflows, and supply chain resilience, platforms like Altium are enabling better decisions and stronger design-to-manufacturing integration.

Great products happen when everyone can see, contribute, and align in real time. Altium Develop gives your entire team, from engineers to procurement, the freedom to work as one. Discover how.