Designing for the Heat: Thermal Management in Collaborative PCB Workflows

When electronic systems fail, heat is often the silent culprit. It creeps into power modules, sneaks behind display glass, and settles into datacenter racks with quiet intensity, gradually building up until it causes performance issues, component degradation, or even system failure. As devices become more compact and more capable, managing that heat has become a common thread that connects every design decision in modern PCB development.

Thermal performance now influences stackup choices, layout strategies, mechanical integration, and compliance pathways – essentially defining how a system will perform in the field. For engineers working in collaborative environments, it's become a discipline that crosses traditional boundaries. The good news? New materials, smarter modeling tools, and increasingly connected workflows are making thermal management more precise, more predictable, and more integrated than ever before.

Thermal Management Isn't a Tweak – It's a Core Priority

Thermal planning now begins before the first trace is routed. Power density is climbing, cooling space is shrinking, and users expect devices to run fast and stay cool. These demands have elevated thermal management. Today’s thermal-aware teams are asking important questions like these earlier in the design process:

-

Where will the hotspots form in this power distribution network?

-

Can we dissipate heat through the board, or do we need chassis coupling?

-

How will flex regions or multi-board assemblies affect thermal gradients?

The answers to these questions influence everything from component placement to mechanical form factors.

Tools, Materials, and Strategies for Thermal Management

New advanced thermal interface materials (TIMs) provide efficient heat transfer in compact spaces. Gap fillers, high-conductivity pastes, and phase-change materials provide flexibility for heat dissipation without adding bulk.

On the PCB itself, stackup planning is critical for thermal performance. Engineers select substrates and copper weights based on thermal targets, using high-Tg laminates and thick inner layers to spread heat laterally, while heavy copper planes ensure thermal resilience under load.

Layout optimization also plays a key role. Thermal vias are strategically placed beneath hot components, copper pours are added to interior layers, and clearance rules preserve thermal pathways.

Simulation tools are critical in this process, providing current density heatmaps that help engineers identify potential hot spots before production, reducing the risk of thermal issues later in the design cycle. This early feedback enables engineers to adjust trace widths, reroute power, or optimize copper relief.

Thermal Management in 3D and Multi-Board Designs

The rise of 3D models and multi-board assemblies has added complexity to thermal planning, requiring engineers to consider the interactions between boards in a system.

In rigid-flex designs, thermal behavior must be evaluated across fold zones and mechanical anchor points. For rack-mounted or enclosure-based products, airflow and mechanical contact surfaces play a critical role. Consumer electronics pose the greatest challenge, requiring thermal solutions that fit within tight spaces where large heat sinks or redundant copper planes aren't feasible.

Effective thermal design now requires seamless coordination between mechanical and electrical teams. Engineers must understand how enclosure shape, heatsink geometry, and airflow interact with copper traces. This is why thermal strategy should be integrated into the 3D co-design process.

Common Thermal Practices for Engineers

Many engineering teams now design systems where the enclosure doubles as the heat sink, using thermal interface pads (TIPs) – rather than paste – between hot components and the chassis. When properly implemented, this approach improves thermal transfer in compact systems, but it requires validation for surface temperature, air buildup, and long-term reliability.

Active cooling has also evolved. Smaller, quieter fans now provide significant airflow. Engineers can source 5V fans and related fan control ICs like the Analog Devices MAX6650 for efficient thermal regulation.

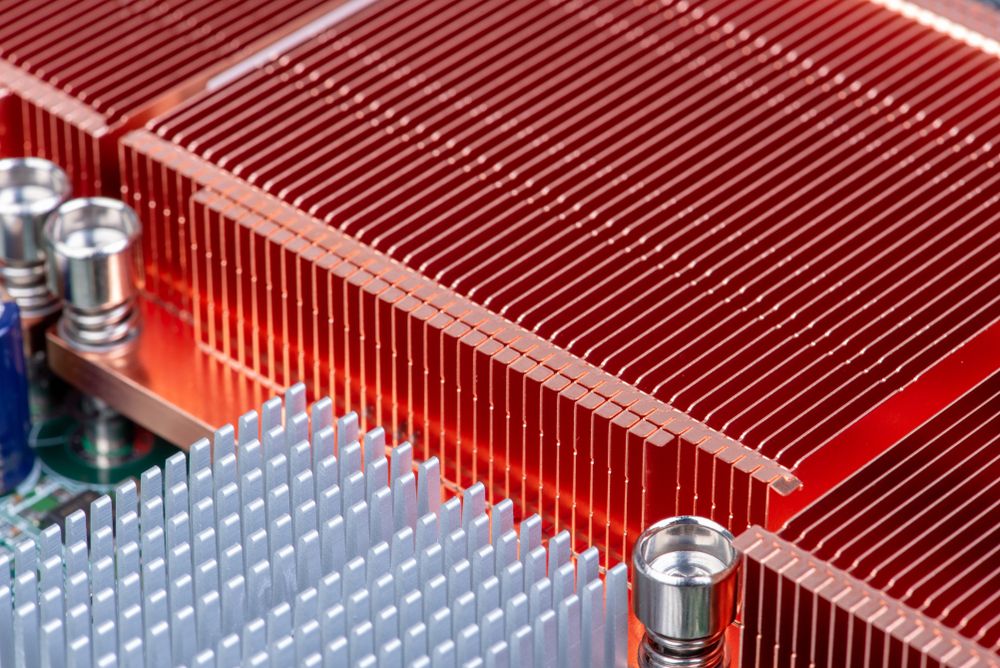

For more demanding passive cooling, custom-extruded heat sinks are popular. Many heatsink vendors listed on Octopart offer heatsink customization, allowing engineers to work closely with mechanical partners to ensure proper alignment and coupling between components and enclosures

Thermal Management Best Practices

Leading engineers utilize a blend of art and science in their PCB thermal strategies. Key principles include:

- Thermal simulation from the start: 3D modeling and simulation tools can predict heat flow and address thermal bottlenecks early.

- Strategic placement: Distribute high-power components and connect them to thermally robust copper planes to avoid hotspots.

- Layered defense: Create parallel heat escape routes with a layered approach using TIMs, thermal vias, metal core substrates, and heat sinks for better resilience.

- Continuous monitoring: Embed sensors and use firmware to monitor and respond to temperature changes during operation.

Working Together to Stay Cool

Thermal management may be a physical challenge, but it’s also a team sport. From layout and enclosure design to compliance, it takes cross-functional coordination and transparancy to keep systems running cool.

Today’s EDA tools make this collaboration possible. PCB layout engineers can annotate hot zones, mechanical designers can evaluate heatsink placement in 3D, and compliance specialists can review copper strategies and material choices, all within a connected design environment. That shared context turns thermal planning into an ongoing feedback loop, not a final checkpoint.

Altium Solutions: Built to Support Collaborative Design

Altium solutions enable engineers to work within thermal constraints while coordinating seamlessly with mechanical teams. While they don't provide high-end thermal simulation, Altium tools support material-aware stackups, copper weight configuration, and thermal via approaches, which can be directly integrated into the electrical layout process.

Designers can visualize copper thickness and power distribution across inner layers, set clearance rules for thermal relief, and ensure IPC standard compliance, all within the same design environment. Rule-based validation ensures that copper width, spacing, and relief strategies remain consistent as the layout evolves, helping maintain thermal efficiency and compliance with design standards.

For systems relying on mechanical enclosure coupling, Altium’s MCAD collaboration tools allow real-time alignment of heatsinks, standoffs, and enclosure-mounted pads with the PCB layout. This is crucial when routing heat through custom brackets or TIM pads mounted to enclosure walls.

Exploring Advanced Thermal Design

For those seeking deeper insights into thermal management, the following resources offer valuable guidance that can help refine your designs:

-

Using PCB Thermal Simulation and Analysis Software in Your Design Workflow

- 10 Top Components for Thermal Management in High-Performance Electronics

These resources bridge the gap between thermal theory and the day-to-day decisions that determine whether your design runs cool or runs into trouble.

Making It Work and Sourcing Smart

Thermal performance shapes everything from system reliability to user comfort. To succeed in today’s design environments, engineers must prioritize three key factors: efficient workflows, seamless cross-team communication, and access to the right tools and components. With Altium solutions and Octopart, engineers can source the right materials, align thermal strategies with mechanical constraints, and work together in real time. Heat may be unavoidable, but with the right design process, it never has to be a surprise.

Finding the right thermal components shouldn't slow down your design process. Octopart connects you with current pricing, availability, and technical specifications on over 32 million parts from hundreds of distributors and manufacturers. The platform's intelligent matching algorithms and comprehensive BOM Tool streamline procurement, whether you're piecing together a complete BOM or hunting down specialized thermal interface materials.