Getting Started for Mechanical Engineers

01- Establish a Live Design Link Between ECAD and MCAD:

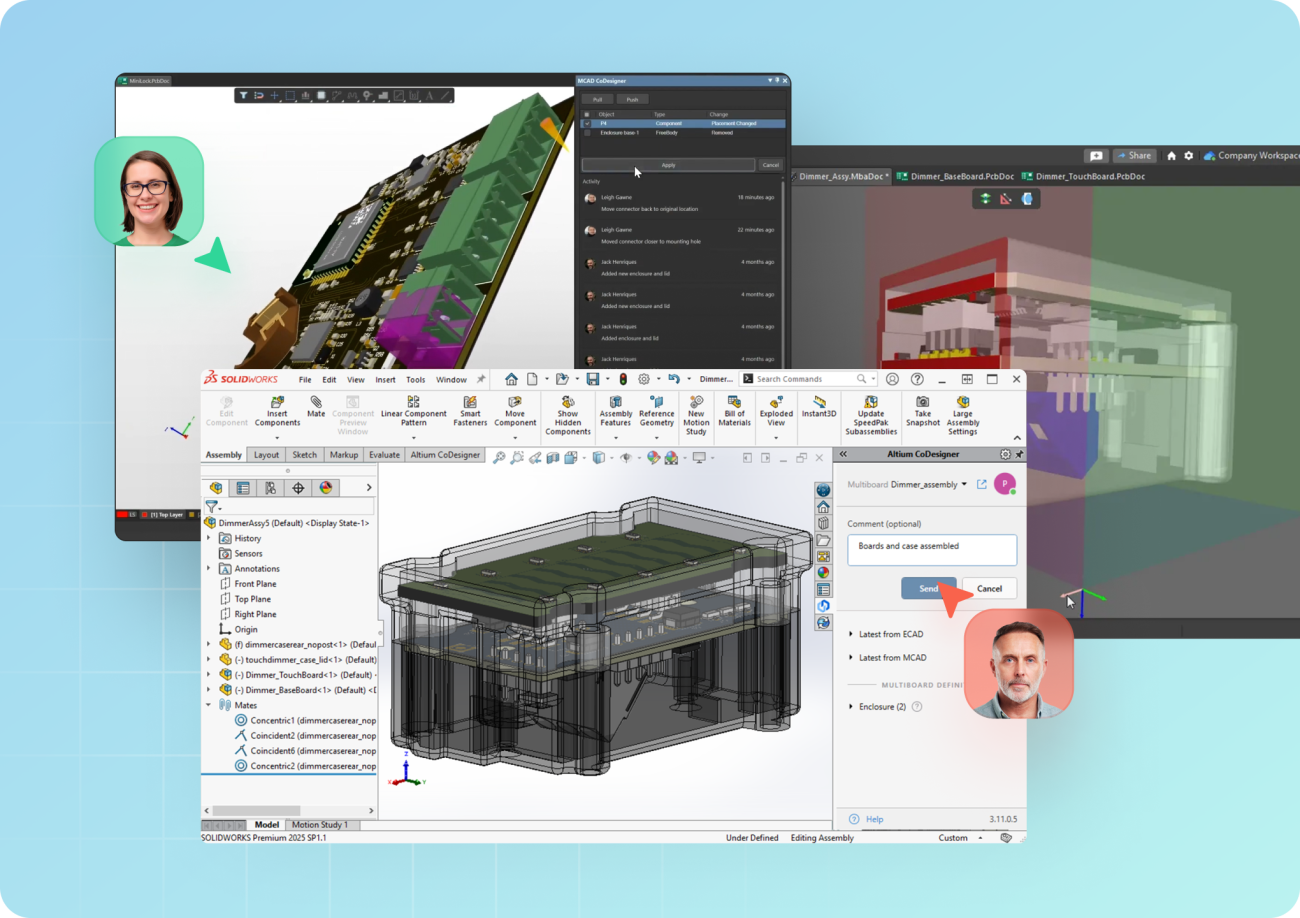

Most electronics teams still rely on static file exchanges like STEP or manual email handoffs to coordinate between departments. As designs evolve, these static files quickly become outdated, leading to component clashes and assembly errors. This guided demo shows how to eliminate that friction by establishing a live, bi-directional link between your native MCAD environment and the PCB layout.

In this walkthrough, you will learn how to:

- Connect your MCAD tool (SOLIDWORKS, PTC Creo, Autodesk Inventor, Autodesk Fusion 360, or Siemens NX) directly to your Altium workspace.

- "Pull" the latest PCB geometry into your assembly as native CAD parts, not just static geometry.

- View a detailed change log of every electrical modification before applying it to your model.

- "Push" mechanical changes—such as board shape or mounting holes—back to the electrical engineer instantly.

- Maintain one version-controlled source of truth that ensures the enclosure and the PCB always stay aligned.

By following these steps, you’ll see how Altium Develop and Altium Agile turn fragmented file sharing into a synchronized workflow, ensuring you are always working with the most current design data.

02-Synchronize Mechanical Constraints and Keepouts:

When mechanical constraints live only in the MCAD model, electrical engineers often lose context, leading to components being placed where they interfere with fan mounts, ribs, or enclosures. This guided demo shows how to communicate physical boundaries directly from your MCAD tool to the PCB layout to prevent placement errors.

In this walkthrough, you will learn how to:

Define "Keepout" and "Room" areas directly within your MCAD assembly to protect mechanical clearances.- Link these constraints to the PCB project so the electrical engineer sees them in real-time.

- Provide comments and design intent alongside the constraint to explain the "why" behind the boundary.

- Update these zones as the mechanical enclosure evolves, keeping the electrical team notified automatically.

- Eliminate the need for manual dimensioning and annotated screenshots to communicate physical limits.

03 - Enable High-Fidelity Thermal Simulation with 3D Copper

MCAD CoDesigner can also transfer the actual copper geometry (referred to as Advanced Copper Geometry) and the 3D mask layers to MCAD. This feature is currently supported by PTC Creo, Autodesk Inventor, SOLIDWORKS, and Siemens NX. From CoDesigner 2.7 onward, the component overlay (silkscreen) decal is applied to the face of the solder mask extrude.

Mechanical engineers tasked with thermal analysis often have to manually recreate copper geometry because standard STEP files lack internal trace and plane data. This manual recreation is time-consuming and prone to error. This guided demo shows how to automatically transfer detailed 3D copper and via geometry into your MCAD tool for immediate use in FEA and CFD simulations.

In this walkthrough, you’ll learn how to:

- Configure MCAD CoDesign to include full 3D copper and via information during the sync.

- Generate native CAD bodies for traces and planes that are recognized by your simulation solvers.

- Identify thermal bottlenecks by analyzing the actual copper density and connectivity in your MCAD environment.

- Perform accurate thermal conduction analysis without relying on simplified material approximations.

- Save hours of modeling time by using the real, manufacturable copper data provided directly from ECAD.

By following these steps, you will see how Altium Develop and Altium Agile provide the geometric intelligence needed for high-accuracy thermal modeling, reducing the risk of overheating and mandatory board re-spins.

04 - Maintain Traceability with Advanced History and Revisions:

When design changes happen rapidly across different teams, it’s easy to lose track of which version is verified. This guided demo shows how to use Advanced History to compare PCB iterations and how to retrieve specific, verified design states to ensure you are always modeling against the correct data.

In this walkthrough, you will learn how to:

- Access the Advanced History log to see exactly who made changes, when, and why.

- Select and "Pull" a specific historical revision of the design directly from the central workspace.

- Eliminate the risk of using outdated or overwritten local files for your mechanical work.

By following these steps, you will see how Altium Agile replaces manual tracking and "file-version-final-v2" confusion with automated, trace-aware version control. You’ll save time, eliminate version errors, and move toward manufacturing with absolute confidence in your data integrity.

05 - Resolve Interferences and Manage Multi-board Assemblies:

Identifying a clash between a component and an enclosure is only half the battle; resolving it usually requires a tedious cycle of manual adjustments. This guided demo shows how to manage complex assemblies with multiple interconnected PCBs.

In this walk-through, you will learn how to:

- Identify component-to-enclosure clashes using your native MCAD interference detection tools.

- Synchronize multi-board product assemblies to perform system-level electromechanical checks.

- Validate that connectors, cables, and boards align across the entire product housing.

- Accept or reject proposed changes with a clear visual preview of the resulting design state.

By following these steps, you will see how Altium Agile connects individual PCB data into a complete system view. You also gain the ability to resolve spatial conflicts concurrently, ensuring that complex, multi-board products assemble without interference.

06 - Master Complex Architectures with Rigid-Flex Sync:

Designing for modern, compact form factors requires precise coordination of multi-board assemblies and flexible circuits. Without synchronization, folding a flexible PCB into a tight enclosure often results in mechanical interference or stress failures. This guided demo shows how to manage complex product assemblies and rigid-flex state synchronization.

In this walkthrough, you will learn how to:

- Synchronize multi-board product assemblies to perform system-level electromechanical checks across all PCBs.

- Define and exchange rigid and flexible regions to ensure the PCB meets the specific needs of portable device geometry.

- Manipulate the board’s folded or flat state in MCAD and communicate geometry modifications back to ECAD.

- Validate that connectors, cables, and boards align across the entire product housing without collisions.

- Ensure the final board shape accounts for the physical "bend" radius required for successful assembly.

By following these steps, you will see how Altium Agile enables you to design for today’s portable devices with confidence, ensuring complex rigid-flex and multi-board systems fit and function as intended.

07 - Streamline Electromechanical Connectivity with Harness Synchronization:

Managing wiring harnesses often involves manual measurements and disconnected spreadsheets, leading to incorrect wire lengths and assembly delays. This guided demo shows how to provide mechanical engineers with electrical connectivity data directly in MCAD to obtain accurate physical lengths and wire properties.

In this walkthrough, you will learn how to:

- Receive electrical connectivity information, including wire properties and connector details, directly in your MCAD assembly.

- Use native MCAD routing tools to define the physical path of wires and bundles within the enclosure.

- Obtain accurate physical lengths for all wires and bundles automatically from the 3D model.

- Synchronize those physical lengths back to ECAD to finalize manufacturing documentation and BOMs.

- Eliminate manual data entry and "string-line" measurements for cabling and harness design.

By following these steps, you will see how Altium Agile bridges the gap between electrical connectivity and physical routing, delivering accurate documentation and reducing harness manufacturing errors.