BOM Sourcing at Scale: How to Source Large BOMs with Ease

Electronics procurement teams rarely enjoy a break from sourcing challenges. If not managing immediate changes in their supply chains, their attention turns to the search for more efficient and cost-effective components or resilience-building efforts – ongoing BOM management.

As such, companies must regularly update large BOMs through effective BOM sourcing – often containing hundreds of entries – and sift through lines and lines of parts with myriad alternatives for almost every component. Not only is this a taxing process, but revisiting it dozens – over even hundreds – of times throughout the product lifecycle can be a significant drain on resources.

So, there comes a need to simplify this process in order to, firstly, streamline the response to changing requirements, and secondly, to deliver on their customers’ demand for cost reduction.

What is BOM Sourcing?

BOM sourcing refers to the process of identifying, selecting, and procuring components for a bill of materials (BOM) to ensure accuracy, cost-efficiency, and supply chain reliability. For large BOMs, effective BOM sourcing at scale is critical to minimizing delays and optimizing production, and tools like Octopart's BOM Tool make this process seamless.

Why Should Procurement Revisit Large BOMs Regularly?

Reevaluating large BOMs at regular intervals is essential to sourcing efficiency and supply chain resilience. With hundreds of parts in motion, the ability to rapidly reassess and adapt is key to minimizing risk and controlling cost.

1. Track Shifting Component Availability

Electronic components move quickly through global supply chains. As distributor stock levels fluctuate due to demand, manufacturing schedules, and global events, a component that was once in stock may fall short with rippling effects. You only have to look at the automotive sector and the impacts of semiconductor shortages to understand the value of availability data. For instance, major automakers like Ford and GM were forced to halt vehicle production for weeks due to a sudden shortage of microcontrollers and power management ICs. With accurate, up-to-date availability data, companies can pivot faster, source alternatives, and adjust forecasts to avoid costly delays.

2. Avoid Obsolescence Surprises

If not addressed in good time, obsolete or end-of-life (EOL) components can severely impact how a product is manufactured. A smartphone manufacturer may facilitate BOM reviews of its microcontrollers, which can become obsolete due to software adaptations, hardware design configuration, and general functional changes.

3. Seize Cost-Saving Opportunities

Component prices shift significantly as a result of supplier policy, global demand changes, or fluctuations in raw material costs. Regular BOM review gives procurement the power to identify areas for savings and reveal more alternative parts, creating contingencies in the event of change.

4. Ensure Compliance Continuity

Rechecking the BOM ensures all selected components remain compliant. Failure to do so can result in costly redesigns, product recalls, shipment delays, or even regulatory penalties, particularly in highly regulated industries.

For instance, medical device manufacturers must adhere to strict regulatory standards like RoHS and REACH, and changes in these regulations can render certain parts non-compliant.

Another industry that places particular importance on compliance is aerospace and defense. While components for the industry tend to have longer lifecycles, suppliers can inevitably discontinue parts over time. This makes last-time buys and alternative component due diligence crucial for maintaining tight deadlines and meeting strict requirements long-term.

5. Align with Engineering Updates

Design changes can halt development or production if not remedied in a timely manner. Revising and updating BOMs as a matter of course limits the events in which procurement teams are caught off guard.

6. Build a Resilient Supply Chain

Proactive BOM management strengthens a company’s ability to navigate supply chain shocks. Whether a result of rippling geopolitical instability, material shortages, or transport delays, any disruption is easier to manage with an up-to-date BOM – and records of past versions.

How Often Should Procurement Revisit Large BOMs?

The product lifecycle can influence how often companies reevaluate their BOMs, but when sourcing at scale, frequent reassessment becomes essential. Large BOMs are more susceptible to shifting requirements, fluctuating part availability, and distribution challenges, all of which call for dynamic sourcing strategies. Up-to-date visibility with BOM sourcing can support significant cost and supply chain advantages.

Organizations can strengthen their large-scale sourcing efforts by embedding due diligence into routine procurement workflows. Lifecycle stages, from product development through to mass production, heavily influence how and when BOMs are reviewed, ensuring sourcing remains agile and optimized.

Product Development

During early-stage development, BOMs are highly dynamic. Engineers and procurement managers collaborate closely on BOM sourcing to frequently update part selections as designs evolve and new requirements arise.

Pre-Production

Prior to production, procurement revisits the product BOM to confirm parts availability, cost-effectiveness, and compliance. This step helps avoid delays and substitutions during the manufacturing process.

Mass Production

During the predominant production phase, BOMs are reviewed periodically – often monthly or quarterly – as part of ongoing cost optimization, as well as ensuring supply chain continuity and the introduction of new compliance requirements.

One-Off Supply Chain Disruption

Few scenarios highlight the value of rapid BOM sourcing and analysis more than those disrupting entire supply chains. The need to act could be influenced by obsolescence, price spikes, or even more significant geopolitical events, namely instances like the Suez Canal blockages or longer-term issues that require companies to pivot.

Engineering Changes

Design revisions and Engineering Change Orders (ECOs) require prompt BOM management to ensure alignment between design intent and procurement capabilities. Procurement leaders can leverage Octopart’s BOM Tool to manage changes – whether due to functional updates or regulatory shifts – by streamlining part selection and sourcing through access to up-to-date data from hundreds of distributors and millions of components.

Streamline Large BOM Sourcing with Octopart

Managing large BOMs can often feel overwhelming, especially when accuracy and speed are critical to production timelines. But with the right tools, procurement professionals can significantly reduce manual work and streamline their BOM sourcing workflows. Octopart’s BOM Tool is designed specifically to address the challenges of BOM sourcing for handling complex, multi-line BOMs with intelligence, speed, and ease.

Currently, Octopart supports BOM uploads with up to 500 lines per file. However, users can upload multiple files in sequence, making the tool fully capable of handling large, enterprise-scale BOMs. For oversized projects, simply split the BOM into smaller files, upload and export results, then continue with the next batch. The experience is seamless and fully supported. The tool is free to use, requiring only a free account to get started.

Below are five key features that simplify and enhance procurement efficiency at bulk sourcing.

1. Intelligent Part Matching and Normalization

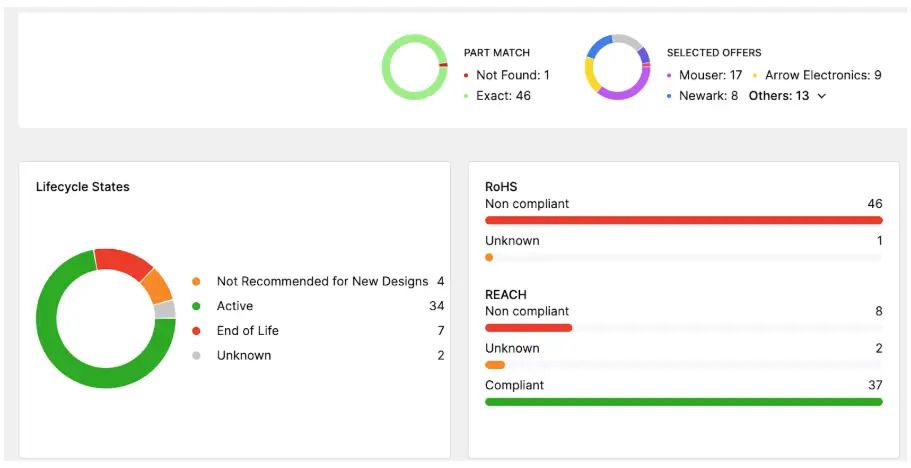

Upon upload, Octopart identifies and normalizes parts through its database. If multiple valid matches are found, a revamped interface allows users to select the intended part. Intelligent part matching reduces the manual effort required to cross-reference manufacturer datasheets and ensures greater accuracy in part identification.

2. Efficient Handling of Multiple Matches

Manual sourcing is time-intensive, especially when multiple options exist for each component. The BOM Tool displays all matched options in a user-friendly format, making it easy to review and select alternatives when needed. This supports procurement professionals in making confident decisions without extra legwork.

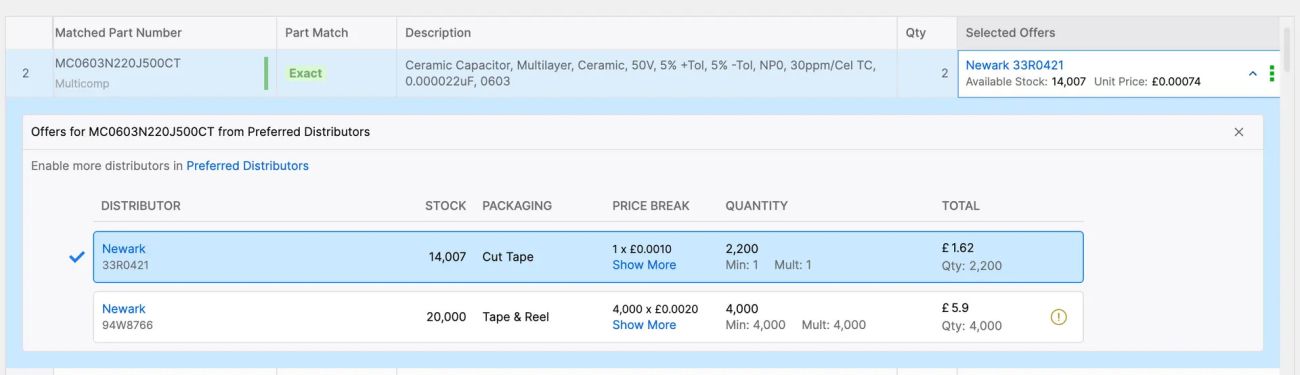

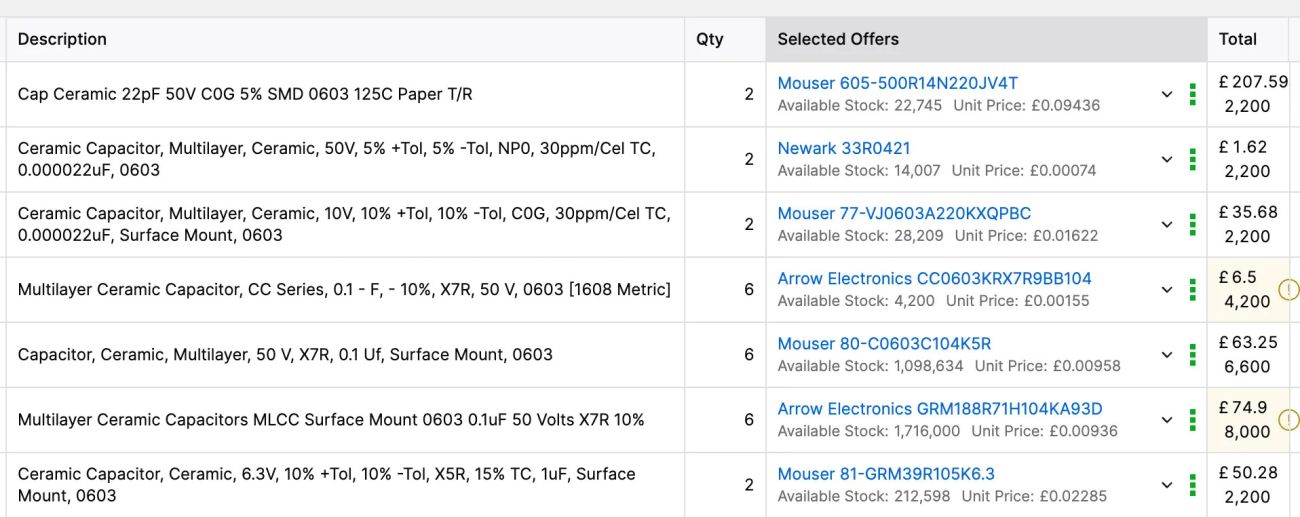

3. Automated Offer Comparison and Selection

The BOM Tool sources offers from a user’s list of preferred distributors, automatically comparing parts based on specified quantities, minimum order quantities (MOQ), and desired lead times. By default, the lowest-priced, in-stock option is selected, removing the need to manually evaluate pricing tables and availability from search result pages.

4. Comprehensive Offer Visibility

Users can drill down into each part to view all available offers from their preferred distributors. The Selected Offers summary keeps track of what’s been chosen, offering transparency and control at every step.

5. Streamlined Purchasing

Once a costed BOM is in place, users can proceed to purchase through Octocart. This feature redirects to pre-built carts on distributor sites, eliminating the need to build carts manually elsewhere and expediting the purchasing process.

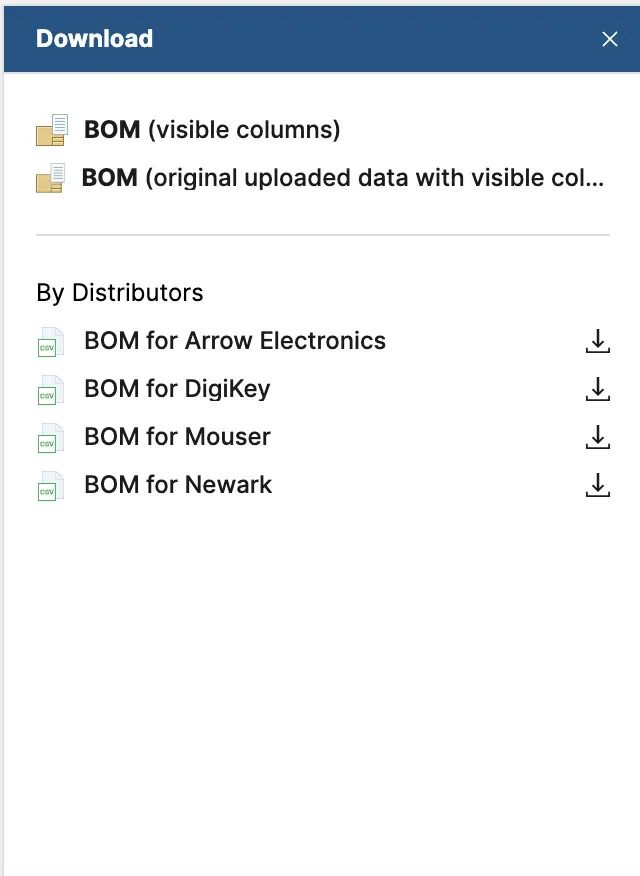

For users who need to complete their work outside Octopart, the “Excel” export enables seamless merging with the original BOM file – no reformatting or manual cleanup required.

BOM Tool for Procurement Efficiency and Resilience

Integrating Octopart's BOM Tool into procurement workflows transforms the way you approach BOM sourcing for components. Whether you’re an engineer working with rapid design iterations or a procurement professional managing component lifecycle risks and supply chain disruptions, proactive oversight of BOM sourcing becomes a core advantage.

No matter the complexity or scale of your BOM, Octopart empowers you to take full control of your sourcing strategy, from initial concept to full-scale production. With smarter tools, clearer insights, and up-to-date data, procurement teams move faster and make informed decisions.

Try Octopart BOM Tool today and see how it simplifies your BOM sourcing workflow at scale.