Octopart Research + Altium = One Powerful Workflow

Every PCB designer knows the drill: research and select components that meet specifications, document your decisions, and somehow keep track of it all throughout the design process. Between searching for available parts that meet project requirements, checking stock availability, and capturing documentation, the overall procurement process can consume a significant portion of design time. And as designs become more complex, each step becomes increasingly critical to track.

The Designer's Daily Challenge

A typical designer’s workflow involves constant context switching: searching for parts in multiple browser tabs, checking specifications in different requirement documents, and implementing designs in their design environment. This fragmented approach does more than just interrupt the creative flow – it increases the risk of specifications being overlooked during component selection and makes it challenging to maintain clear documentation along the way.

The challenge becomes particularly acute when designs need modification. Months after making initial component selections, engineers often struggle to reconstruct their decision-making process. Which specifications drove the selection of this voltage regulator? Why was this particular power management IC chosen over alternatives? Without easy access to requirements during the design process, critical selection criteria can be lost in the shuffle between applications and documents.

Octopart Research in Practice

For many designers today, the component selection process typically begins with Octopart.com, the leading electronic component database. With data on 72 million components from more than 400 distributors, Octopart's intelligent search capabilities interpret technical queries with remarkable precision. Enter specifications like voltage ranges, temperature requirements, or package types, and the system matches them against detailed component parameters. This intelligence makes what was once a tedious process into a streamlined search experience.

More than 16 million parts in the Octopart database include CAD models, enabling quick validation of footprints and mechanical specifications. When supply chain issues necessitate component changes, you can quickly identify and evaluate replacement options using a parametric search. The system helps you find parts with similar – or, in some cases, better – specifications, ensuring alternatives meet your design requirements.

Setting Up Requirements in Your Designer Environment

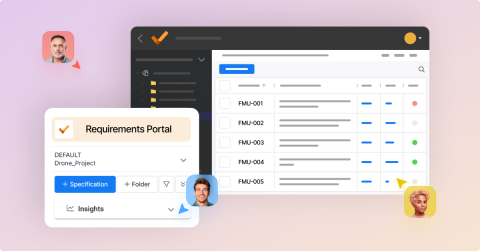

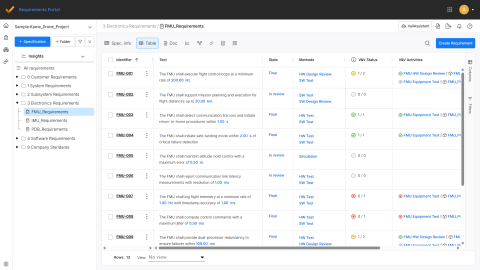

Requirements Portal within Altium Develop and Altium Agile Teams brings requirements directly into your Altium Designer environment through the Designer's Requirements panel. This panel serves as a command center for your requirements, displaying everything in a hierarchical structure that mirrors your design organization. See Figure 1.

Setting up project-requirement links thoughtfully from the start pays dividends throughout the design process. Through the Requirements region in Project Options, you can establish connections between your design project and requirements blocks. The Link Requirements dialog presents a hierarchical view of available requirement blocks, making it easy to create logical connections between your design project and its specifications. See Figure 2.

Consider your project's structure when linking requirements. The hierarchical organization provides the ability to map requirements to specific aspects of your design – for instance, connecting power management requirements to the corresponding design blocks.

Each requirement tile displays key information, validation settings, and direct links to its instance in the Requirements Portal, ensuring you're always designing against current specifications. This structured approach becomes particularly valuable as projects grow in complexity, helping maintain clear relationships between specifications and implementation.

Working with Requirements During Design

With your requirements properly linked, the Requirements panel provides three essential capabilities that transform how you interact with specifications:

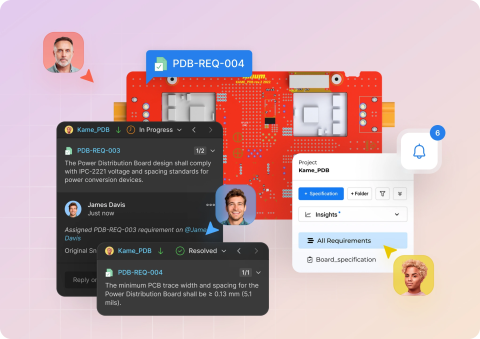

First, you can place requirements directly on design elements, creating clear links between specifications and implementation. This placement system works similarly to Altium Designer's familiar comment system – you can associate requirements with specific points, objects, or areas in your design. These placements create a visible trail of requirement implementation throughout your design. See Figure 3.

Second, you can assign requirements as tasks when verification or implementation requires attention. When creating a task, add detailed descriptions to ensure a clear understanding of what needs to be verified or implemented. Task assignees receive notifications and can update the status through the Comments and Tasks panel, maintaining clear communication about requirement implementation. See Figure 4.

Third, you can update the verification status as you confirm compliance with specifications. The verification menu in both the Requirements panel and document requirement dialog shows clear progress indicators, such as how many verifications have been completed out of the total required for each requirement. See Figure 5.

Streamlined Component Selection

With requirements directly accessible in your design environment, component selection becomes more systematic. When researching parts in Octopart, you can quickly reference specifications from the Requirements panel, ensuring selections align with project requirements. The ability to place requirements directly on design elements creates clear documentation of which specifications drove particular component choices.

Dynamic Filtering for Design Workflows

The Requirements panel's filtering capabilities help you maintain focus during different design phases. Using the filter, you can create focused views for different tasks. For example, when working on power distribution, you can filter to show power-related requirements.

This filtering becomes particularly valuable during design changes and component modifications. By toggling between filtered and unfiltered views, engineers can quickly identify which requirements might be impacted by proposed changes. The ability to see both specific requirements and their broader context helps ensure no critical specifications are overlooked during modifications.

Verification Workflow in Practice

The verification process in Altium combines automated checks with engineer-driven validation. The system can automatically verify certain design parameters – like board layer count or other project-level specifications – against requirements. When violations occur, they're flagged immediately, allowing quick identification and resolution of issues.

Beyond automated checks, the verification menu in the Requirements panel provides a structured approach to manual validation. The menu displays verification progress – showing, for example, that one of three verifications is completed – helping teams track their progress through the validation process. This combination of automated and manual verification helps ensure thorough requirement compliance while keeping engineering judgment at the forefront of the process.

Enhanced Design Efficiency

Together, Octopart’s comprehensive component data and Altium’s integrated requirements management system work in concert to create more efficient workflows. You can move confidently from initial component selection through final verification, knowing your choices align with project requirements every step of the way. This integration transforms what was once a fragmented process into a streamlined workflow that enhances both productivity and design quality.

Interested in creating one powerful workflow? Discover Altium Requirements Portal today!