Stretchable Sensors: Built to Move

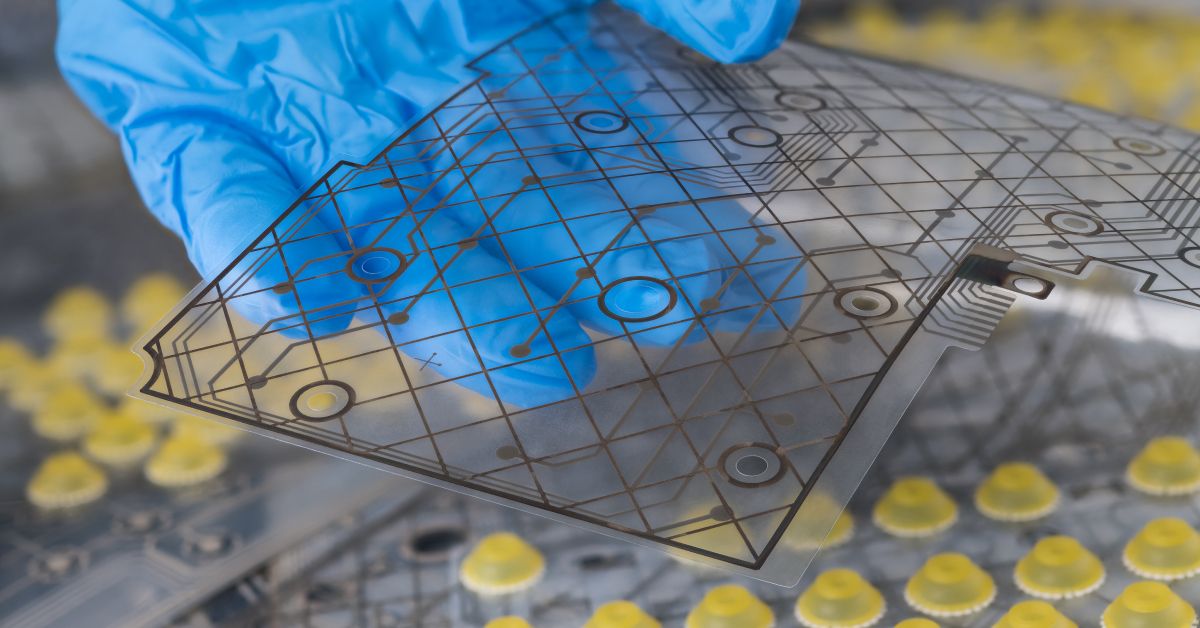

Across sports tech, medical monitoring, and soft robotics, flexible sensing systems are moving from promising concepts into production-ready components. At the center of this trend are stretchable sensors, devices that flex, stretch and conform to the body or irregular surfaces while reliably capturing physical data.

These sensors are now robust enough for real-world deployment. In this article, we’ll explore leading sensor types, highlight commercial technologies and cover the practical challenges engineers face when designing with stretchable components.

Why Stretchable Sensors Matter

Traditional sensors are built for rigid substrates. But new applications, from VR gloves to robotic skins, demand components that can stretch, flex and move with the system.

Stretchable sensors close the loop between motion and digital feedback. Fitness wearables and VR systems use them to track movement naturally. In medical devices, soft biosensors improve patient comfort during long-term monitoring. And in robotics, pressure-sensitive skins help machines detect touch, grip variation or surface irregularities in real time.

Key Types of Stretchable Sensors

Stretchable sensors aren’t one-size-fits-all. Different types support different signal needs, from force and motion to bioelectric activity, with each unlocking new capabilities in flexible electronics.

Strain sensors measure deformation - how much a material is stretched or compressed - by tracking resistance changes in conductive elements. They’re essential for wearable motion tracking, soft robotics and smart textiles. These sensors excel at detecting subtle bending, elongation and joint movement in systems like exosuits and biomechanical feedback loops.

Pressure sensors respond to force applied across a surface. Stretchable versions use deformable substrates with layered conductors to deliver consistent output under compression. They’re ideal for prosthetics, robotic grippers and tactile maps where touch sensitivity and mechanical resilience must coexist.

Biosignal sensors detect biopotentials from muscles (EMG) or cardiac signals (ECG). Stretchable biosensors conform to the skin, reducing irritation and improving signal consistency over time. They’re increasingly embedded in medical patches and rehabilitation garments where long-term comfort and continuous monitoring are priorities.

Pioneering Commercial Technologies

Interlink Electronics offers a range of flexible force sensing resistors (FSRs), including the FSR 400 Series. These sensors are ultra-thin, durable and highly flexible, making them ideal for integration into curved and dynamic surfaces. Common uses include wearable interfaces, robotic skins and pressure-sensitive input devices. Interlink’s sensors are distributed through Digi-Key and Mouser, simplifying sourcing for engineering and procurement teams.

StretchSense specializes in soft, stretchable motion sensors integrated into gloves and garments for VR/AR systems, fitness tracking and rehabilitation. Sensors measure stretch across joints and limbs, enabling high-resolution motion capture without rigid encumbrances. Products are available directly from the StretchSense online store and are used commercially by VR companies and developers of performance wearables.

Tacterion develops tactile sensor skins using its proprietary “pliable tech” platform. These flexible pressure sensors stretch and conform to irregular surfaces, enabling responsive touch interfaces in robotics, automotive interiors and advanced human-machine interfaces. Development kits are available through the company’s website, and the sensors are already in use in robotic grippers and adaptive product surfaces.

Real-World Deployments and Applications

Stretchable sensors are no longer confined to R&D. They’re powering commercial products across industries.

In wearables, embedded strain and pressure sensors monitor posture, gait and athletic performance in real time. StretchSense has partnered with glove and VR headset makers to develop high-resolution hand-tracking gloves.

In health tech, flexible biosignal sensors are being integrated into rehab garments and soft exosuits that provide real-time feedback without restricting mobility.

And in industrial robotics, flexible tactile skins, like those developed by Tacterion, are helping grippers safely handle delicate or irregularly shaped objects - a task that traditional rigid sensors simply can’t manage.

Design Challenges with Stretchable Sensors

Designing with stretchable sensors pushes engineers into new territory where circuits flex, signals shift and reliability is earned through foresight. Success comes from mastering these challenges before they stretch your design too far.

- Signal stability under deformation: As materials stretch, electrical properties can drift. Careful sensor selection, calibration strategies and strain distribution management are essential to capturing reliable data during operation.

- Connector and interconnect design: Standard rigid connectors aren't built for dynamic movement. Engineers need to select flexible interconnects or design strain reliefs to prevent mechanical failure at attachment points.

- Packaging and encapsulation: Environmental protection must not compromise flexibility. Thin, flexible encapsulants like thermoplastic elastomers (TPE) or silicone-based materials can help balance durability and freedom of movement.

- Power and signal conditioning: Stretchable sensors sometimes generate weaker signals compared to rigid systems. Amplification and filtering circuitry must be designed to accommodate signal variability without adding bulk or rigidity.

From Prototype to Production: What Changes?

Stretchable sensors often perform well in controlled demos, but production environments introduce new stressors. Over long lifetimes, issues like sensor delamination, inconsistent adhesion and calibration drift can emerge, especially in wearables where temperature, moisture and movement vary constantly.

To make the leap from proof-of-concept to product, design teams should account for:

- Flex cycle testing to ensure sensor reliability after thousands of uses

- Connector durability, especially if the device will be worn, washed or recharged frequently

- Stable manufacturing processes for layering and embedding sensors without introducing stress points

Planning ahead for these challenges can prevent costly late-stage surprises during validation or certification.

Sourcing Considerations for Stretchable Sensors

The market for stretchable sensors is still maturing but advancing fast. While many vendors offer innovative technology, not all support scalable supply chains, stable lead times or standardized part numbers. When evaluating these components, engineers and sourcing teams should prioritize parts with clear lifecycle status, robust datasheets and support for common packaging or integration formats.

Tools like Octopart simplify this process. Engineers can compare prices, check availability and identify at-risk parts before they derail a project. Octopart’s free BOM Tool helps teams manage component choices and evaluate substitutes as the design evolves.

What's Next for Stretchable Sensing?

Today’s stretchable sensors are already pushing boundaries. Tomorrow’s higher-density sensing arrays will enable more detailed spatial mapping, especially in tactile robotics. Some research groups and a few startups are embedding AI directly into sensor nodes, providing on-sensor data processing that reduces latency and improves responsiveness.

Advances in biocompatible stretchable electronics are opening new frontiers in continuous health monitoring, offering the potential for stretchable biosignal patches that move naturally with the body for weeks at a time.

While many of these technologies are still emerging, today’s commercially available stretchable sensors already provide powerful tools for engineers ready to build flexible, responsive products right now.

Stretchable Sensors Are Just Getting Started

For decades, we've adapted our bodies to rigid technology by hunching over keyboards, holding devices at awkward angles and accepting the discomfort of hard edges against soft skin. Stretchable sensors flip this relationship. In a world where technology increasingly lives on and in our bodies, the future belongs to electronics that bend, stretch and flex without breaking.