CAD Layout Software for Modern PCB Design and Modern PCB Designers

Back in the day, PCB designers drew schematics by hand. Instead of guiding a mouse, technicians used red and blue pencils to carefully draw pads and traces on vellum parchment paper. Their tools included a triangle, a T-square, and templates. Forget a thorough design process involving CAD tools, full team collaboration, differentiated schematic diagrams and circuit board designs - one was lucky enough to have a steady hand.

After completing a draft, traditional PCB designers positioned the pencil drawing and a grid sheet on a flat light table. Overlaying the pencil drawing with a sheet of mylar, they placed sticky donut pads and used a knife to create a pad master drawing. They then covered the pad master and drawing with another layer of mylar and used black tape and a knife to define traces for the PCB.

Although commonplace at the time, the old ways were rudimentary, at best, in comparison with today’s Computer Aided Design (CAD) layout software. With intuitive design rule checking, routing assistance and auto-routing tools, multi-layer and multiboard technology, and plenty of simulation features, it almost feels like you can have your devices fully planned out and made before they even hit the electronics production phase of manufacturing.

The Evolution of CAD Layout Software

Since the old days, CAD layout software has propelled PCB design into the future. Now, sophisticated tools allow you to draw, design, and develop a schematic or product drawing. During the PCB design process, CAD layout software allows you to map component positioning and connections. Typically, CAD layout software also helps designers visualize how nets connect to components.

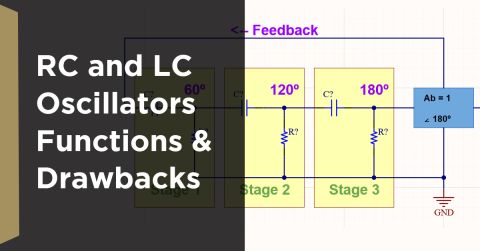

By capturing the schematic within CAD layout software, designers can now run simulations that test the operating characteristics of the circuit. In addition, they can establish board dimensions and clearly understand the impact of adding multiple layers. CAD layout software also assists with managing the routing for each layer, the drilling information for components, and the footprint for board pads.

Effectively, contemporary design processes have enabled it so that not only can you rely on your circuit board design tools to have the features you need to produce the requisite circuits, but also manage the PCB data and files from schematic symbols and schematic design to PCB footprints to Gerber file formats. If you’re using software which doesn’t seem to make one or more of these design processes easier, it might be time to upgrade to modern layout programs.

PCB Footprints, Schematic Diagrams and Moving to a Finished Design

In the first days of PCB design, a large precision camera was used to create negatives of the outer layers. These negatives worked as a temporary mask, protecting the copper laminate from the acid used during the manual process of PCB etching. Hand soldering connected through-hole components to the PCB, while a blueprint assembly drawing indicated the polarity, value, and package number for the component placement and soldering.

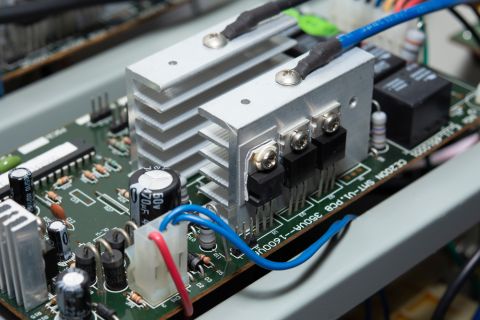

Even with today’s superior CAD layout software, modern PCB design is a complex undertaking due to consumer and industrial requirements. This complexity drives the need for progressively better tools. A well-rounded view of PCB design and circuit board design software that provides ample resources to tackle the challenges presented by high-speed, multilayer PCB designs is ideal. A complete set of unified tools would emphasize the interconnected nature of design.

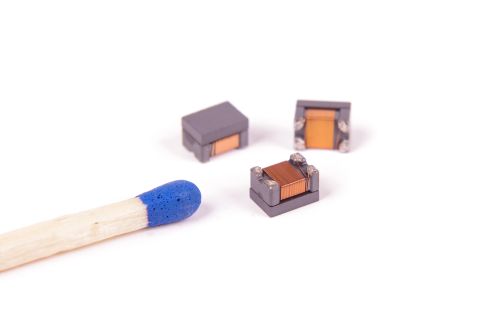

For instance, take schematic capture to a new level by allowing you to design small single-layer circuits or large multilayer arrays. Capturing a schematic connects components obtained from libraries. Wire pins together and place net identifiers to connect pins to the net. Bundle multiple nets into a bus while any combination of nets and buses can bundle into a signal harness. Know that you can manage vias and microvias in a thoroughly secure rules engine.

Your workspace can be as adaptive as your PCB designs

With schematic capture, you can build your design in sections: the processor and memory section, the analog-to-digital processing section, the power supply, and the display interface. Furthermore, find printed circuit design software that can capture individual sections on separate schematic sheets, transfer the section to its PCB editor, and transfer additional circuits as you build the complete design.

If needed, you should also be able to reuse existing circuits through a copy/paste/reannotate process. This approach to modular design vastly enhances design readability. Using multiple sheets also allows several designers to simultaneously work on a project. Hierarchical design establishes the relationship between the sheets and connects a child sheet to a parent sheet. Multiple people can work on the same design at different stages in the process this way.

PCB Routing and Preparing for Manufacturing, Fabrication, and Assembly

PCB design once involved using negatives to apply a temporary mask that protected copper laminate from acid. The desired trace pattern was achieved by manually applying the etchant to the board using gloves, tongs, goggles, and timers, while the solder mask was manually applied to the PCB with a screening process. I can’t even imagine how many re-printings had to occur when circuit boards inevitably had solder mask errors and solder bridges being formed.

Past methods seem ancient when compared to auto-interactive routing. Interactive routing attempts to define a route path from a pad to a current cursor location. You can use auto-interactive routing by clicking on a pad and selecting a connection for routing. Routing width design rule and track width mode settings control track size, while routing conflict resolution modes allow the router to respond to existing objects and apply conflict resolution strategy.

Interactive routing can involve a single net, a differential pair, or a set of selected nets. This way your traces can be made as secure as you need them to be, and you won’t have to worry so much about your design surviving its fabrication period. Furthermore, circuit board design software has enabled an easier, reliable relationship with small or large batch PCB manufacturers as you can give them clearer required information in output files.

File Formats and Team Integration in Your CAD Tools

After you have used a combination of tools to build your design, the best PCB design software allows you to test the DC power distribution network throughout your PCB. The PDN Analyzer™ (Power Delivery Network) enables you to repair power connections before moving on to prototyping, thereby minimizing time and cost. You can also import system enclosures and mechanical constraints to assess functionality and fit before prototyping.

MCAD and ECAD software and team collaboration have never been easier than with a PCB design software which is built around easy-to-read file formats. When you can have the different departments looking in on the PCB as its being designed, your team can prepare for designs coming down the pipeline in advance and effectively make everybody work more efficiently.

Make sure that your boards obey design rules to be produced functional and safe

It should come as no surprise that throughout this piece, I’ve been using the capabilities and features that Altium Designer® provides in its design software as exemplary for what to demand from your own layout software. Ever since using Altium, and especially with its latest version, Altium 18, the layout software has reached new heights in integrative software technology and easy layout designing.

Take every stage of your design process equally as serious and choose a software which values working in a unified, user-friendly interface overall. Your PCB design tool should be expected to make your job easier, not add unnecessary and stressful processes to getting your circuit board into its enclosure as planned.

To learn more about optimizing your PCB design process with the most versatile CAD layout software, talk to an expert at Altium.