Dual Rail Voltage Supply

The highest performing operational amplifiers often need a split supply with positive and negative voltages connected to the op amps supply rails. In this project, we’re going to be building a positive/negative dual rail power supply for a differential oscilloscope probe I’m designing. I’m making the power supply a separate project, as a dual rail supply is quite useful to have, and I’m sure I’ll find multiple uses for it in the future.

In the past, I’ve talked on this blog about dual power supply configurations, however in this project we’re going to implement that advice and build a negative regulator.

As my differential probe is going to be connected to a wide range of signals, I want to ensure the power to the op amps is not only very stable and low noise, but also completely isolated from both the oscilloscope and the device under test. Therefore, this board will be powered by a 9V battery. AA batteries would be nice, however would need a switching regulator on both the positive and negative supply, and with just two AA batteries the run time would be limited. More than two AA batteries are too bulky, and these problems are worse with AAA batteries.

The 9V battery is readily available in a wide variety of stores at low cost, there are rechargeable options, and importantly for me: there are no shipping restrictions on them. Lithium ion batteries would add substantial complexity to the design relative to using a 9V battery, with charging and battery monitoring circuits - furthermore, it's incredibly difficult to get them delivered to where I live. If you’d like to read a more in depth analysis of different battery technologies and how they relate to electronics applications, take a look at my Octopart article on choosing batteries.

As with all of my projects, you can find the open source Altium Designer files for this project on my GitHub licensed under the permissive MIT license.

Advantages of Using a Dual Supply

When using a single-supply op amp, the output voltage can only span from near to the voltage input to near to the ground. How near, depends on the specific op amp with rail-to-rail amps generating output signals almost completely to the supply rails.

If you are working with waveforms that have a negative component, such as AC, or you need your output voltage level to be exactly 0v, then a dual supply op amp will give you the versatility you require. Some of the highest performance op amps on the market are also designed with a dual supply voltage requirement, therefore if you need to push the limits a dual supply voltage may be mandatory.

Some op amps may require the maximum/minimum input voltages to be several volts from the supply rail. If you are using a 5 volt single-supply on an op-amp with a 2 volt minimum offset, you only have 1 volt of usable input span. Rail-to-rail amplifiers can solve this problem, as can a dual supply.

For my differential probe, I’m expecting to be looking at AC waveforms primarily, using some very high performance op amps, which necessitates the use of a split supply for powering them.

Negative Rail

In a previous project, I created a negative supply for an operational amplifier using a charge pump, however that project only required a minimum supply current and voltage rail quality. I’d like this dual supply to provide very high quality power at 80mA or more. While that is not a lot of current, it is more than many charge pumps offer, and I need substantially lower noise.

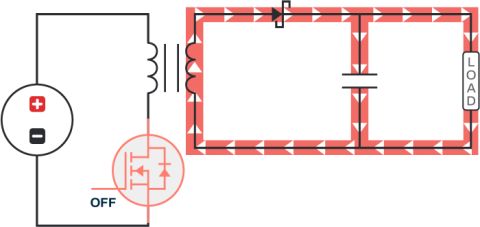

The topology for the negative rail on this supply will be a switching power supply to generate a -5.5V supply, which will be cleaned up by an LC filter that feeds into a linear regulator.

Switching Regulator

Many engineers these days see negative voltages as something almost mythical as most modern devices only require a single positive supply to operate. There’s really nothing to creating a negative voltage however, If you can design a step-down voltage regulator you can design a negative regulator - the theory is exactly the same.

To create the -5.5V supply, I’m using the Maxim/Analog MAX17578 4.5V to 60V, 1A High-Efficiency, Synchronous, Inverting Output DC-DC Converter. Switching regulators are not great under low loads, yet even so with 80mA of load on this regulator it should still be operating at around 66% efficiency. This may not sound like it is very efficient, however it is far higher than any other in-stock regulator at the time of design.

Linear Regulator

The final output of the negative rail is provided by an ultra low noise linear regulator, the Analog Devices ADP7182. To remove the switching noise from the -5.5V regulator, I have added an LC filter to the input. The regulator should be capable of dealing with the switching noise, however it is always a good idea to help things out as much as possible when aiming for low noise.

The LC filter may be perfectly capable of supplying clean enough power for some applications, allowing the expensive linear regulator to be removed, so a 0 ohm resistor allows the input and output of the linear regulator to be shorted. A design variant ensures that this resistor will not make its way into the BOM or assembly information when it is not required.

While my initial use for this regulator needs +/-4.8V, I do want this design to be versatile and applicable to other uses. Therefore, I have added a trimmer pot to the adjustment pin for the regulator, allowing the voltage to be adjusted from -4.2V to -5.2V. A multi-turn pot would be ideal here, but the mechanical constraints of how I envision this board being used limit me to a single turn pot.

Do your projects need variants and optional components to ease manufacturing while providing more configuration options? Talk to an Altium Expert today, or sign up for a free Altium trial.

Positive Rail

The positive power rail is much simpler than the negative, with just a linear regulator connected to the battery. With low current draw, there is no need for a switching regulator. Running the regulator directly from the battery ensures the lowest noise on its input.

The schematic for the positive regulator is very similar to the negative regulator as the Analog Devices ADP7102 linear regulator is in the same family as the negative regulator. Again, the voltage can be adjusted from +4.2V to +5.2V using the same trimmer pot model as the negative regulator.

The positive regulator also has a voltage divider for the enable pin, where the linear regulator on the negative rail does not need this feature as the switching regulator provides this function.

Low Battery Warning

I like over engineering things, so for this project I have an over the top low battery warning. Rather than just having an LED come on when the battery is low, I'm instead going to have a flashing low battery LED.

I’m using one op amp (IC5) to detect the low battery level, the output of which powers a relaxation oscillator circuit utilizing another op amp (IC6). Another name for a relaxation oscillator is an astable multi-vibrator. The relaxation oscillator drives a MOSFET which flashes the LED. The oscillator op amp is sufficiently low current draw to run it directly from the output of the low voltage detection amplifier.

A relaxation oscillator generates a square wave output, with this one designed for around 1Hz frequency and a 50% duty cycle. A relaxation oscillator charges a capacitor, C21 in this case, which is connected to the inverting input of the op amp. The non-inverting input of the op amp is connected to a voltage divider.

While the capacitor is discharged, its voltage will be below the non-inverting input, allowing the capacitor to charge from the op amp’s output through R29. Once the capacitor is charged, the inverting input will be higher voltage than the non-inverting input, and the opamp output flips allowing the capacitor to start discharging.

PCB Layout

The PCB for this project is relatively simple, the size of the board is determined by the battery holder, power connector and the need for a mounting position for a standoff to go between boards. The board will be a 1mm thick, four layer board. Both of the internal planes are ground pours, with the outer layers for signal routing. This ensures the routes have an excellent return path on an adjacent layer.

The board has a lot of stitching vias to thoroughly connect the ground nets together, aiming to reduce conducted and radiated noise. The layout of the switching regulator is just a typical switched mode layout, with the linear regulator layouts not being overly critical.

I have tried to keep the switching regulator as far from the power connector as makes sense, while keeping the linear regulators as close to their output pins as possible.

The ground pour provides an excellent thermal path for the positive regulator which will be dissipating the most heat.

I have test points on the board arranged so the most critical signals (the voltage rails) can be probed by an oscilloscope with a spring ground connection to minimize the ground loop length. Testing any hardware that contains a switching component using the ground lead on the scope probe is a great way to pick up near field noise in addition to or instead of the signal you’re actually looking for.

Performance Testing

There’s no point building a regulator if you’re not going to try it out, so let’s throw the regulator on the lab power supply and hook it up to my DC Load to see how it performs. All of the tests below were performed on the lab power supply, however I did also check the loads with the regulator running on a battery, the results were indistinguishable.

While the current tests are being performed through a fairly thin wire jumper into the board, checking the onboard voltages with both my benchtop multimeter and handheld multimeter the readouts on the DC load are with a couple of millivolts of what is on the board.

Negative Rail

Starting testing on the negative supply side, the no load voltage is 4.8149V. I could probably trim this a little better, but I was impatient to see how it would perform under load.

My DC load only supports positive voltages, so I simply used the negative rail as the ground reference and the regulator's ground as the positive input. As far as the DC load is concerned, this is a positive voltage.

You can ignore the load resistance in the photo below, this is a fraction of a second before the load was applied and the DC Load was measuring the load as it ramped up the current.

Under load, we can see a 24mV drop in the output. The datasheet claims Accuracy over line, load, and temperature of +2% maximum/−3% minimum. With half a percent deviation in voltage, it definitely falls within this claim at 80mA.

Given the regulator is performing well at its design load, I wanted to push it to 200% to see how it would fare. The regulator is rated for -200mA of load, so it should be absolutely fine. The voltage dropped by 44.2mV under the increased load, but that is still only a 1% drop, and well within the claims of the datasheet.

Looking at the switching regulator on my oscilloscope without a load applied, things look stable and it’s handling the low low very well. The only load on this regulator is anything parasitic plus the 4mA of current driving the LED. Some switching regulators just do not cope with this little load, so it is nice to see everything is stable.

Switching on the DC load, set to 80mA of current draw, the switching regulator’s output looks a lot more like what you'd expect a switched mode regulator to look. Adding the RMS voltage measurement to the display, we can see that while the peak to peak noise is around 26mV, the RMS noise is only about 2.2mV.

Taking a look at the signal after the LC filter, we can see that all of the switching noise is completely removed, however the signal is a bit of a dogs breakfast. For my initial application of this board, the linear regulator will definitely be staying on the board, as the linear regulator cleans this mess up nicely.

Positive Rail

On the positive rail, we can perform the same tests to see how comparable the linear regulators are. I chose the regulators to have a good performance match, but it’s always a question of how well things perform in the real world rather than on paper.

With no load, I have the voltage set a little higher than the negative regulator is, at 4.8492V.

Under the designed load of 80mA, we can see the voltage has dropped a little less than the negative regulator, with a loss of just 18.6mV. This is a little under 0.4 percent of the original voltage. While this is more accurate than the negative regulator, this makes sense as the positive regulator’s datasheet also claims higher precision with Accuracy over line, load, and temperature of −2%, +1%.

Increasing the load to 200%, the voltage drops by 30mV, or 0.6% of the original set voltage. Again this is still better than the negative regulator, but it does surprise me somewhat as the positive regulator has a current rating of 300mA, rather than the 200mA of the negative voltage regulator. The voltage drop is still well within the datasheet’s specifications however.

Combined Voltage

Testing each voltage rail is interesting to see the performance of each regulator, however is somewhat meaningless beyond verifying that the regulators are working as expected. In the real world, my op amps will be getting fed the dual supply voltage, loading the regulators equally.

I have the positive regulator connected to the positive input of my DC load, and the negative supply connected to the ground input for my DC load. This shows a 9.6574V voltage to the DC load with no burden on the supply.

Adding the design load of 80mA to the regulator, we see a 22.1mV drop, or just 0.2% of the original voltage. I’m very pleased with this result, knowing that my op amps will be getting a very stable voltage even as their load might change during use. This should ensure I have very consistent outputs.

Increasing the current to 200%, we now have 32mV of total voltage drop, or just over 3 percent of the unloaded voltage.

Using my oscilloscope to look at the output of the regulator board, while under load, it’s somewhat unenlightening. While it does look as though there is a lot of noise and action happening, with the oscilloscope measuring 242 microvolts of RMS noise, this isn’t the regulator board we’re seeing. The screenshot below has 2 seconds of persistence enabled, and is color graded to show the most frequently occurring signals.

So what do I mean by this isn’t the regulator board we’re seeing? Unfortunately, my oscilloscope’s noise floor is just too high. My Rigol MSO5354 oscilloscope measures 450 microvolts of RMS noise when measuring a 47 ohm through hole axial resistor with the probe (one leg wrapped around the ground band, the other leg around the probe tip). So there’s no way I can directly measure the 15-18microvolts of noise the datasheets tell me to expect from these linear regulators. While disappointing, I do find it amusing that the noise measured from my regulator board is lower than the noise measured from a resistor.

I also tried this test with the regulator running on a battery and loaded with a 100 ohm resistor to see if the noise performance was any different, ruling out my test equipment as a noise source. Other than the resistor getting very hot and smelling pretty bad, there was no discernible difference on the oscilloscope between the two input voltage/load methods.

Final Thoughts

While I wish my test setup would allow me to look more closely at the noise level on the outputs, I’m still happy with the result of this regulator design. It’s always nice to push the limits of test equipment with projects.

In addition to the tests above, the board has also spent over a day sitting at 200% load without any signs of failure or stress. The positive linear regulator was the hottest component on the board, reading around 65 degrees Celsius. (149°F) while my lab's room temperature hit a sweltering Scottish summer peak of 22.5°C (72°F).

In my next project, I’ll be putting this board into action powering three high performance operational amplifiers as I build a differential oscilloscope probe that will stress the limits of my test equipment even further.

Are you using industry leading schematic capture and PCB layout tools to develop your hardware solutions with the least amount of effort? Talk to an expert at Altium to find out how Altium Designer can accelerate your next project. Alternatively, sign up for a free trial to see what all the fuss is about!

Back

Back