How to Design Current Measurements in Sensors and Power Electronics

Current monitoring is used in sensor interfaces and power electronics; the measurement requirements are very different but the methods are quite similar. This feature involves both analog circuits (dividers, shunts, comparators, amplifiers) and digital processing. The design hinges on required accuracy, space, and signal type (slow sensor voltage, fast power rail transient, or switching current), which determine the measurement front-end and components.

This article focuses on the common interfaces that can be used for current measurements in both types of designs. You could have a requirement for low current measurements (such as in sensors), or for a high current measurement (in power electronics), but with minimal impact on the system in each case (i.e., minimal voltage drop).

Define Current Measurement Requirements

What are you measuring? Designing a current monitoring interface begins by defining what the circuit must sense and under what conditions. For current, this includes knowledge of the nominal load, as well as an estimate or measurement of transients, such as from startup inrush.

- Shunt value

- Amplifier gain/offset

- Measurement reference voltage value

- Filter bandwidth

Low-side or high-side current? When sensing current, the choice between low-side and high-side measurement depends on the system's ground and supply architecture. Low-side sensing (resistor between load and ground) is best used for a single load, or each load in parallel as there can be a connection directly to the PCB ground plane. However, this creates a risk of a ground potential offset (i.e., a ground loop) when currents are large. High-side sensing (resistor between supply and load) does not have this risk, and it detects upstream faults, but requires an amplifier tolerant of the full common-mode supply voltage and transients. Floating loads, grounds, or interacting ground domains may necessitate galvanic isolation.

Before starting schematic capture, define:

- Nominal and worst-case load current or rail voltage (steady-state, transients, startup, fault conditions)

- Required measurement resolution and sampling rate (slow monitoring vs. fast transient capture)

- Acceptable voltage drop or attenuation (for current shunts or voltage dividers)

- Power dissipation limits (especially for shunt resistors under high current)

- Grounding and isolation approach (low-side vs. high-side sensing, need for isolation)

Choosing a Current Sensing Strategy

Shunt-Based Current Measurement

A common and straightforward way to measure current is to place a shunt resistor in series with the load (either high-side or low-side) and measure the small voltage drop across it.

- Shunt resistor value: Choose a resistance value that gives an acceptably large voltage drop at maximum load current. In high-current power electronics, the shunt might be a few mOhm, while the shunt resistor can be very large for low-current sensors.

- Resistor tolerance and temperature coefficient: Resistors with high tolerance values and low temperature coefficient are preferred so that the signal is at a level compatible with your ADC or logic domain.

Shunt-based sensing is appropriate when currents are relatively moderate (so that power loss across the shunt is acceptable), and the system can tolerate the small voltage drop; also useful when accurate, repeatable measurement is needed and isolation is not strictly required.

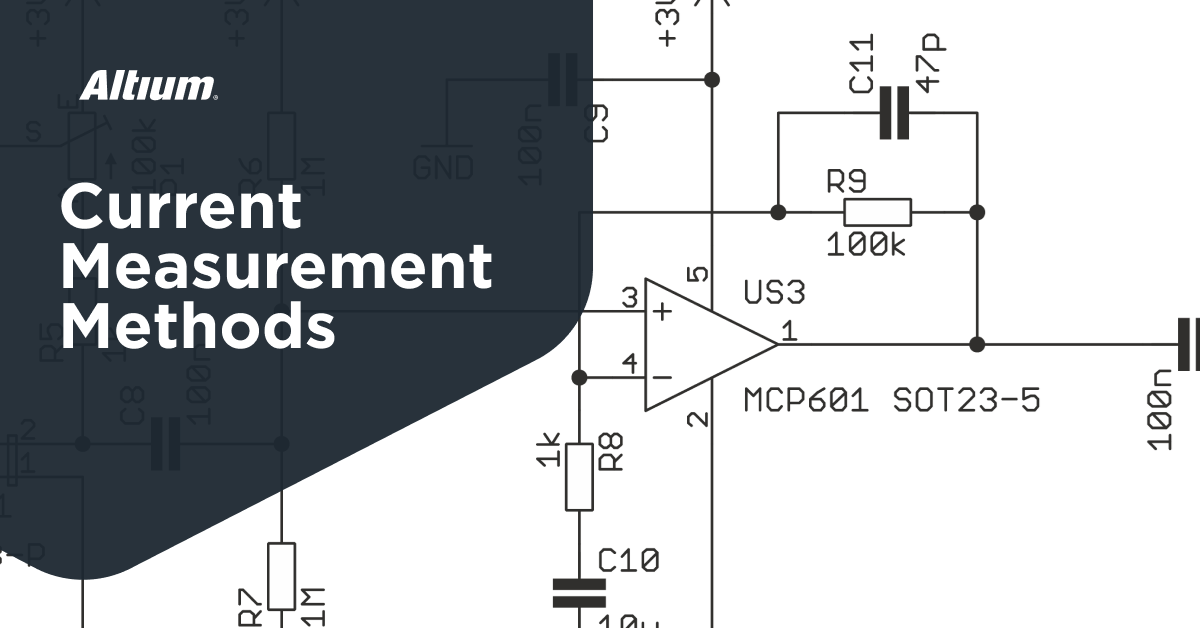

Using Instrumentation Amplifiers or Current-Sense Amplifiers

To make the small voltage developed across a shunt resistor measurable, you typically place a gain stage between the shunt and the ADC or microcontroller.

How to implement the amplifier stage:

- Choose a suitable amplifier type: A dedicated current-sense amplifier or precision instrumentation amplifier provide continuous monitoring with a voltage as an output.

- Place amplifiers near current/voltage sources: Minimize trace length between the shunt and amplifier inputs. Long traces can receive millivolt-level signals from noise sources.

- Grounding: Make sure the ground pins on an amplifier are connected to the same net as the ADC ground, including for isolated ADCs.

- Add filtering if needed: If the load current has high-frequency components (e.g., switching currents, PWM ripple), include input filtering. Typically this is an RC filter placed near the ADC input pin.

Amplifier-based sensing is a standard approach that matters when the shunt voltage is small (e.g., few tens of millivolts or less), when measurement accuracy matters, or when you must interface to a microcontroller or ADC that expects signals in a higher voltage range. It is also preferable when high common-mode rejection ratio (CMRR) is needed, or when offset voltage needs to be controlled with an external source.

|

Constraints |

Recommended Approach |

|

Moderate current, acceptable small voltage drop |

Small shunt resistor, low-side measurement |

|

Moderate current, monitoring of total current in multiple parallel devices |

Small shunt resistor, high-side measurement |

|

Continuous monitoring, common-mode noise rejection required |

Instrumentation amplifier or current-sense amplifier |

|

Post-processing or logical conditions required (fault detection, thresholds, flag outputs, etc.) |

Mixed-signal device integrating sensing + custom logic |

|

Low current measurements |

Large shunt resistor, possibly requiring an isolated ADC or optical isolation with amplifier |

|

Simple systems without isolation needs, ground-referenced (not galvanically isolated) load |

Low-side shunt sensing with amplifier |

|

Systems needing fault detection or ground-fault detection, high-side loads, or floating loads |

Small high-side shunt resistor |

In practice, many designs use a combination of approaches given the set of constraints in the above table. For example, a low-side shunt resistor can be used for continuous current monitoring and a mixed-signal processor can be used to apply logical conditions on the sensed current based on amplitude.

Current Measurements With GreenPAK

Renesas offers the GreenPAK line of mixed-signal processors and the Go Configure IDE so that designers can use CPLD-type functionality for a variety of mixed-signal applications, including current measurements. Designers can implement the thresholding approach (with comparators or window comparators) or continuous monitoring (with amps or an ADC).

These processors allow designers to implement both approaches with custom logic using a graphical programming interface, and their system host can reprogram the measurement settings on-the-fly. In addition, programmable logic cells allow for implementation of a wide variety of digital logic functions.

- Adjustment of internal reference voltages and hysteresis windows

- Custom digital logic flow with LUTs, flip-flops, gates, counters, etc.

- Fully customizable pinout, ranging from analog I/Os to serial interfaces

The developer tools in Renesas GreenPAK give designers the ability to develop fully custom digital, analog, or mixed signal ICs. These programmable mixed-signal processors allow consolidation of functions found in power management ICs, allowing for smaller, more efficient systems. To learn more, take a look at the GreenPAK components and reference examples.

Whether you need to build reliable power electronics or advanced digital systems, use the complete set of PCB design features and world-class CAD tools offered by Altium to implement your GreenPAK solutions. Altium provides the world’s premier electronic product development platform, complete with the industry’s best PCB design tools and cross-disciplinary collaboration features for advanced design teams. Contact an expert at Altium today!

Back

Back