Flexible Hybrid Electronics & IoT: A Perfect Match

Do you remember all the fads and obsessions you had as a kid? When I was younger, everyone was crazy about Pokémon and whatever electronic gadgets they could get their hands on. These two crazes eventually combined into one ultimate trend—the Tamagotchi. It was a massive hit, blending the excitement of portable electronics with the charm of tiny, unrealistic digital pets.

Now, two major trends in the PCB world have also converged: Flexible Hybrid Electronics (FHE) and the Internet of Things (IoT).

Over the years, DIY development boards helped kickstart the IoT revolution, and now flexible hybrid electronics is shaping its future. Engineers are designing flexible PCBs and peripherals compatible with big brands like Arduino, opening up endless design possibilities. Want to join the frenzy? Here’s how flexible hybrid electronics are reshaping IoT and why you should be part of it.

Advantages of Flexible Hardware Platforms

Flexible and rigid-flex PCBs were once exclusive to high-tech industries like aerospace and defense, helping rovers explore other planets. Today, their benefits are coming down to Earth, making their way into development boards and IoT peripherals.

Why Flexible Hybrid Electronics?

Flexible Hybrid Electronics (FHE) combines the cost efficiency and performance of traditional electronics with the space-saving and form factor advantages of flexible circuits. While the dream of fully flexible electronics is still evolving, FHE is the practical middle ground.

Instead of relying solely on flexible materials, flexible hybrid electronics mount traditional, optimized components on flexible substrates. This approach:

- Leverages existing high-performance components (familiarity with tried-and-true chips)

- Enhances durability – Some flexible hybrid electronics circuits can bend over 200,000 times before failing

- Optimizes space – Smaller, thinner, and adaptable to unconventional designs

Traditional PCBs have many limitations. They are rigid and fragile, making them prone to breaking instead of bending. Their bulky nature makes it difficult to fit them into tight spaces, limiting design flexibility. Additionally, they struggle with dynamic performance, making them less effective in applications that require movement or flexibility.

Mounting IoT components on flexible substrates solves these problems, making electronics more adaptable and wearable-friendly.

Flexible circuits are the future.

Flexible Hybrid Electronics, IoT, and Arduino: A Game-Changing Trio

The IoT revolution is accelerating, with billions of devices expected to flood the market. Many of these devices are tiny, sensor-based networks designed to monitor infrastructure, track environmental changes, and power smart homes. These gadgets need to be:

- Compact – Fitting into tight spaces

- Low Power – Operating efficiently on minimal energy

- Simple to Develop – Mass production requires plug-and-play functionality

For years, Arduino has dominated the DIY and commercial development board market. What started as a hobbyist platform is now widely adopted in industrial IoT applications.

Now, flexible hybrid electronics are merging with Arduino, unlocking even more possibilities. Companies are shrinking and bending development boards to make them smaller, thinner, and more adaptable.

- NextFlex developed the first flexible Arduino system, proving that FHE can integrate seamlessly into mainstream development platforms.

- Printoo created a range of Arduino-compatible flexible boards, targeting wearables and IoT sensors.

- Seeed Studio experimented with ultra-thin Arduino prototypes, pushing size limits for IoT integration.

You should expect to see other companies and designers try their hand at FHE-based Arduino solutions in the coming years.

The Future of Flexible Hybrid Electronics in IoT

The flexible electronics landscape has drastically evolved, making flexible hybrid electronics a key player in IoT innovation. As industries push for smaller, smarter, and more adaptable devices, flexible hybrid electronics are shaping the future of wearables, automotive technology, and sustainable electronics.

- Wearables & Medical Devices are integrating flexible biosensors for real-time health monitoring, including wearable ECGs, glucose sensors, and skin-adhering circuits for unobtrusive tracking.

- Automotive & Aerospace industries are leveraging FHE for lightweight, durable electronics, including in-mold electronics (IME) for dashboards and airplane interiors, smart vehicle sensors, and conformal antennas for seamless connectivity.

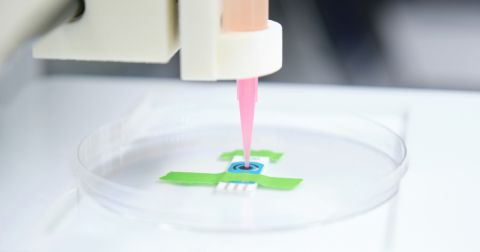

- 3D Printing & Sustainable Electronics are transforming IoT device manufacturing, with custom 3D-printed circuits, eco-friendly biodegradable materials, and next-gen conductive inks like graphene and MXenes for higher performance and efficiency.

With these advancements, FHE is set to redefine the IoT landscape, driving innovation in flexible, efficient, and sustainable electronics.

Flexible Hybrid Electronics: Your Piece of the Pie

The open-source hardware market is booming. Valued at $74.6 billion in 2023, it’s projected to reach $148.2 billion by 2032, fueled by the explosive growth of the IoT. If you want a piece of this rapidly expanding industry, the key is to design boards and peripherals that are simple, familiar, and useful.

Make your designs accessible by ensuring compatibility with existing hardware platforms like Arduino and allowing users to program them with popular IDEs like Cloud9, BlueJ, and Geany IDE. By tapping into the well-established open-source development board community, you make it easier for designers to integrate your hardware into their projects.

But familiarity isn’t enough—your designs also need to be practical for the future of IoT. Wearables demand flexible, lightweight solutions to fit form factor requirements. Low-power wide area networks require hundreds of small, energy-efficient sensors to gather data. And automotive IoT is expanding fast, calling for miniature, lightweight electronics to meet body and weights requirements and to seamlessly communicate with surrounding infrastructure and pedestrians.

The race for the future of IoT is already underway—and flexible technology is leading the charge. Arduino has long been a contender in the IoT space, and now companies are integrating flexible hybrid electronics to push the limits even further.

Why shouldn’t you be one of those innovators? By designing hardware that meshes with existing technology and meets the evolving demands of IoT, you could be at the forefront of the next big wave in open-source electronics.

How to Design Flexible Boards?

There remains only one challenge: How do you design flexible hybrid electronics circuits? Lucky for you, Altium has the answer. It supports both flexible and rigid-flex circuits, providing the tools you need to create innovative designs. With advanced 3D modeling, it ensures that circuits fit perfectly within enclosures, eliminating design constraints. Additionally, its seamless integration with flexible hybrid electronics manufacturing processes simplifies prototyping, making it easier than ever to bring flexible electronics to life.