Meet PCB Designer Tor-Anders Lunder and the Self-tracking Drone He Helped Develop at Staaker

Judy Warner: Tor-Anders, will you please share a little bit about your journey to becoming a PCB and how you ended up at Staaker?

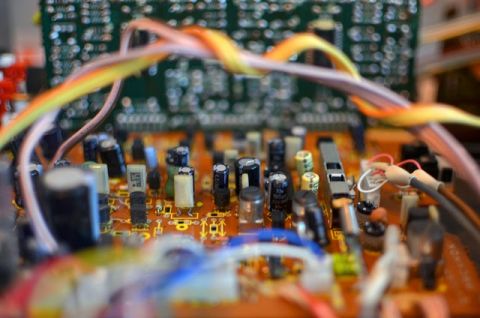

Tor-Anders Lunder: Sure. After my master’s degree at Norwegian University of Science and Technology (NTNU) in Trondheim I had already been doing some projects involving PCB design and was curious about the whole process from design to assembly, and wanted to learn more in this field. I started my career in 2000 as an Application Engineer at Chipcon, A RFIC semiconductor startup that was acquired by Texas Instruments in 2006. At Chipcon I made reference designs and learned a lot about PCB processes and pitfalls to avoid during the design phases. In 2007 I moved over to Radiocrafts and designed radio modules and reference designs for the radio modules. Due to the small form factor, this gave new challenges in PCB design. In 2016, I felt I was missing one last piece of the puzzle--the integration between ECAD and MCAD. I wanted to work more with end product development and Staaker was a perfect match.

Warner: You recently presented a talk at AltiumLive 2017: ANNUAL PCB DESIGN SUMMIT in Munich, Germany. Will you please give us an overview of what you shared, and tell us what compelled you to want to present?

Lunder: The presentation was highlighting the benefit of using the 3D feature in Altium Designer® to enable multi-system PCB design. A Staaker drone design case was used to give insight into how and why 3D models will enable getting it "right the first time" in complex product developments. I was looking for an informal place to learn more about Altium, and in addition, connect with the industry involved in the PCB production and assembly. The AltiumLive 2017 announcement highlighted all these factors so I wanted to join. As a startup it’s a win-win situation to be asked to talk about what we love to do, and in addition, be part of this great event for free, which was offered for all presenters.

Warner: I’m so glad to hear Altium offered a program that was valuable to you, and we certainly appreciate your presentation. What unique challenges do you face designing electronics for a drone--particularly one that is designed for extreme sports enthusiasts?

Lunder: The main challenges are how to minimize noise coupling between subsystems inside the drone and to make the sensors operate optimally under all types of conditions. In addition, EMC considerations for FCC/CE compliance was challenging and time-consuming. (See Staaker drone video here)

Warner: What is your favorite and least favorite part of designing PCBs?

Lunder: My favorite part of PCB design is the art of place and route. I look at it as a complex game of tetris, where all the electrical design rules must be taken into account. This is where I turn up the music, since much of the critical brain work has been done in the schematic layout. My least favorite part of PCB design has been the documentation. However, preparing templates upfront and using Draftsman® in Altium has made this much easier and faster than what I have been accustomed to with other ECAD tools. So, the least favorite part is not that painful anymore.

Warner: Who were your professional mentors, and what role have they played in your career?

Lunder: I learned a lot from my first boss at Chipcon who hired me directly from the University in 2000. His knowledge in all aspects of PCB design and assembly was very helpful when starting to learn the details about the design processes and how to adapt them to design rules in the ECAD tool. He later started his own company, Radiocrafts in 2003, and I joined his team in 2007 and continued to learn from him. This experience served me well when I continued my own path as a hardware at Staaker.

Warner: What advice would you give to a just getting started in the field?

Lunder: To be a good PCB you should invest some time in understanding the PCB production process and what documents fabricators actually need. Avoid redundancy and information not needed. Start with the design rules in your ECAD tool and set them according to your selected fab requirements. If you do not understand a specific design rule, find out what it means and adjust accordingly.

Warner: Any final thoughts you would like to add?

Lunder: I believe that if you have the design rules sorted out upfront and tuned to the PCB factory you will use, the probability of failure will greatly decrease. If you have mismatch between your ECAD design rules and the PCB fab spec, they will adjust your design to comply with the factory process. Some even make changes without asking. What I really miss is an easier integration of design rules between PCB factories and ECAD systems. Design rule import is already supported in most ECAD tools, but the challenge is to get a design rule file from PCB fabricators that include all design rule parameters or is compatible with the ECAD tool.

Warner: That is always a challenge that the industry is trying to address with things like IPC-2581, but we’re not completely there yet! Thank you very much for taking the time to share your expertise with our readers. Good luck with the ongoing success of Staaker!

Lunder: It has been my pleasure. Thank you.