From Scattered Requirements to Confident Product Development

In hardware development, requirements are the foundation of every successful product. But for many teams, requirements still live in disconnected documents, spreadsheets, and emails — far removed from the design and verification work they are meant to guide.

Altium’s Requirements Portal changes that by giving engineering teams a structured, connected way to capture requirements, trace them to designs, and track their verification — directly within the electronics development workflow.

The result is less rework, faster iterations, and greater confidence that products meet both technical and regulatory expectations.

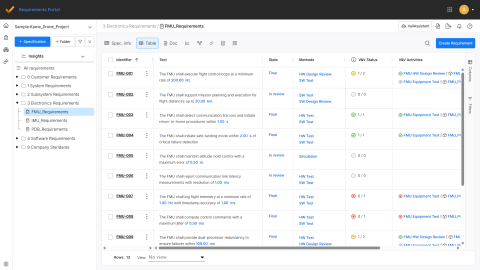

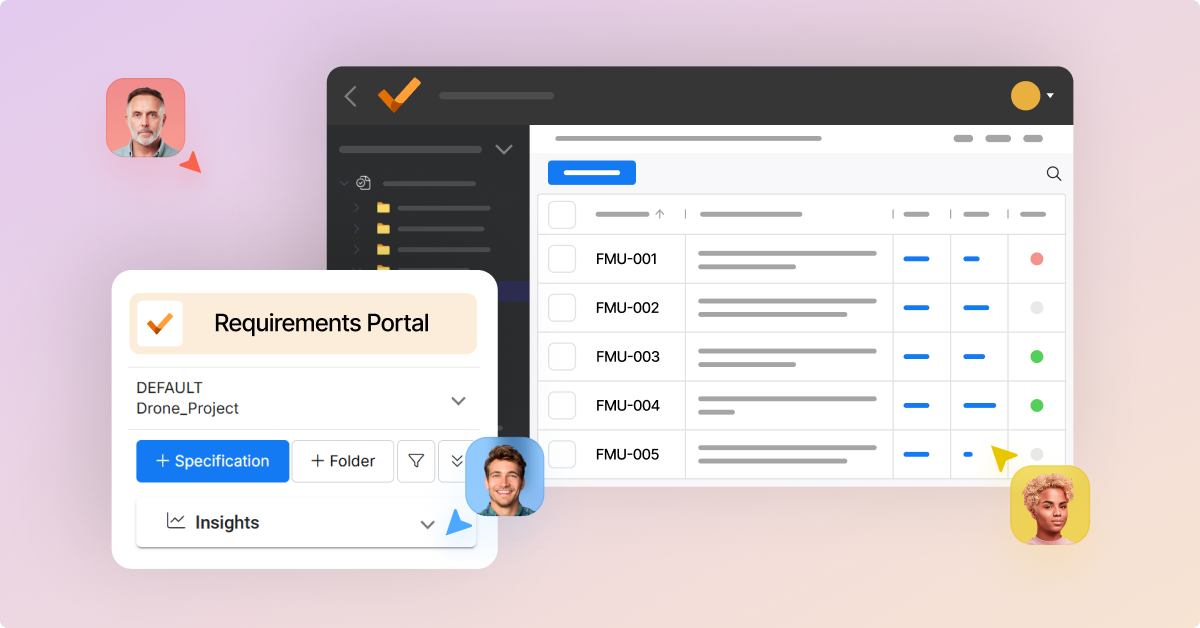

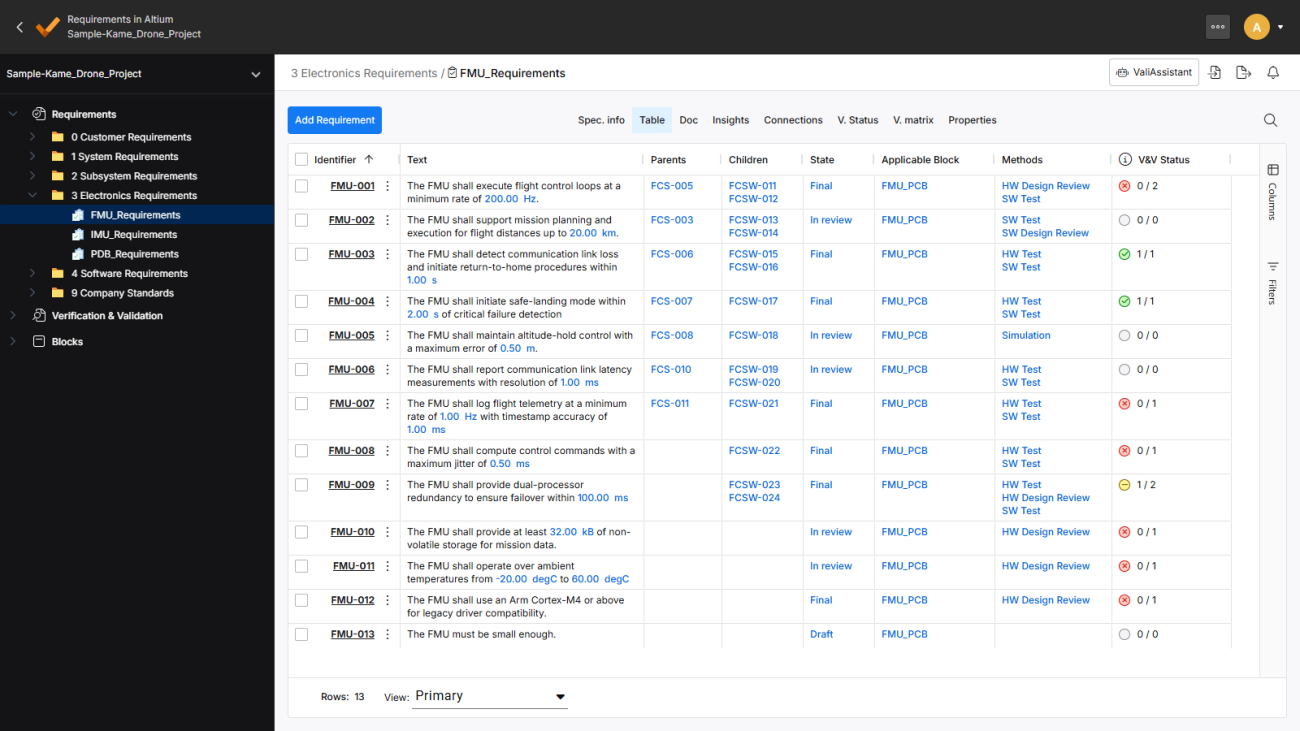

Capture and Manage Requirements in One Place

Altium’s Requirements Portal replaces scattered files with a cloud-based system for managing requirements across engineering projects. Stakeholder, system, and derived engineering requirements are captured in one environment, creating a reliable source of truth that can be accessed by the entire team.

This centralized approach eliminates version conflicts and reduces time wasted searching for the latest specification.

“Requirements Portal has been an instrumental tool, allowing us to gather all-level requirements in one database and ensure full traceability throughout the project's life. Its ease of use, flexibility and scalability are features we really enjoy.”

- Faviola Kettig, Systems Engineer, ISISPACE

With all requirements accessible in one place, teams can scale projects without losing clarity or control.

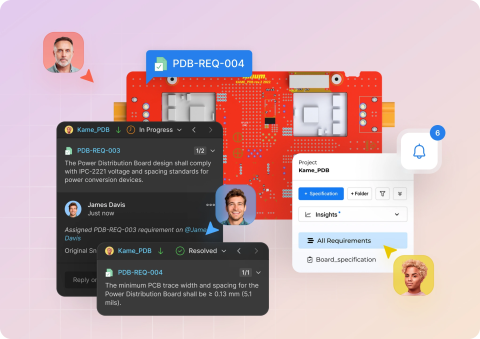

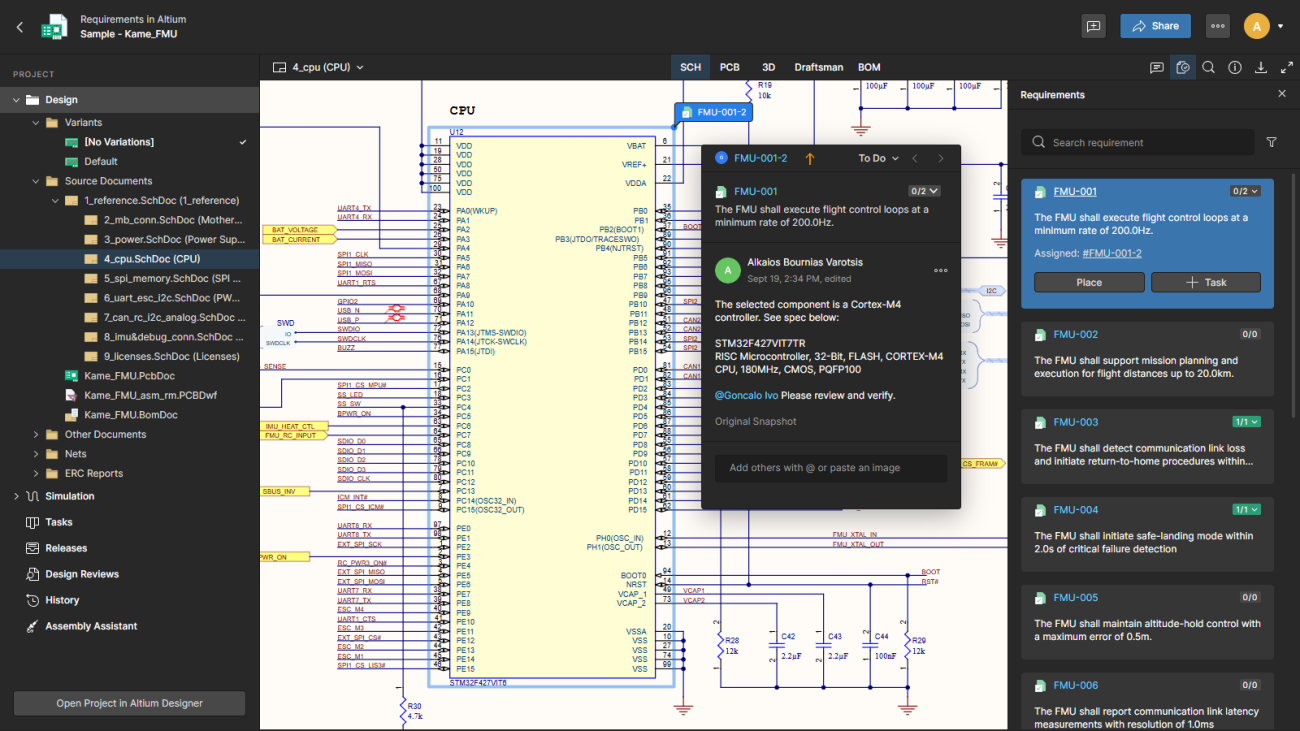

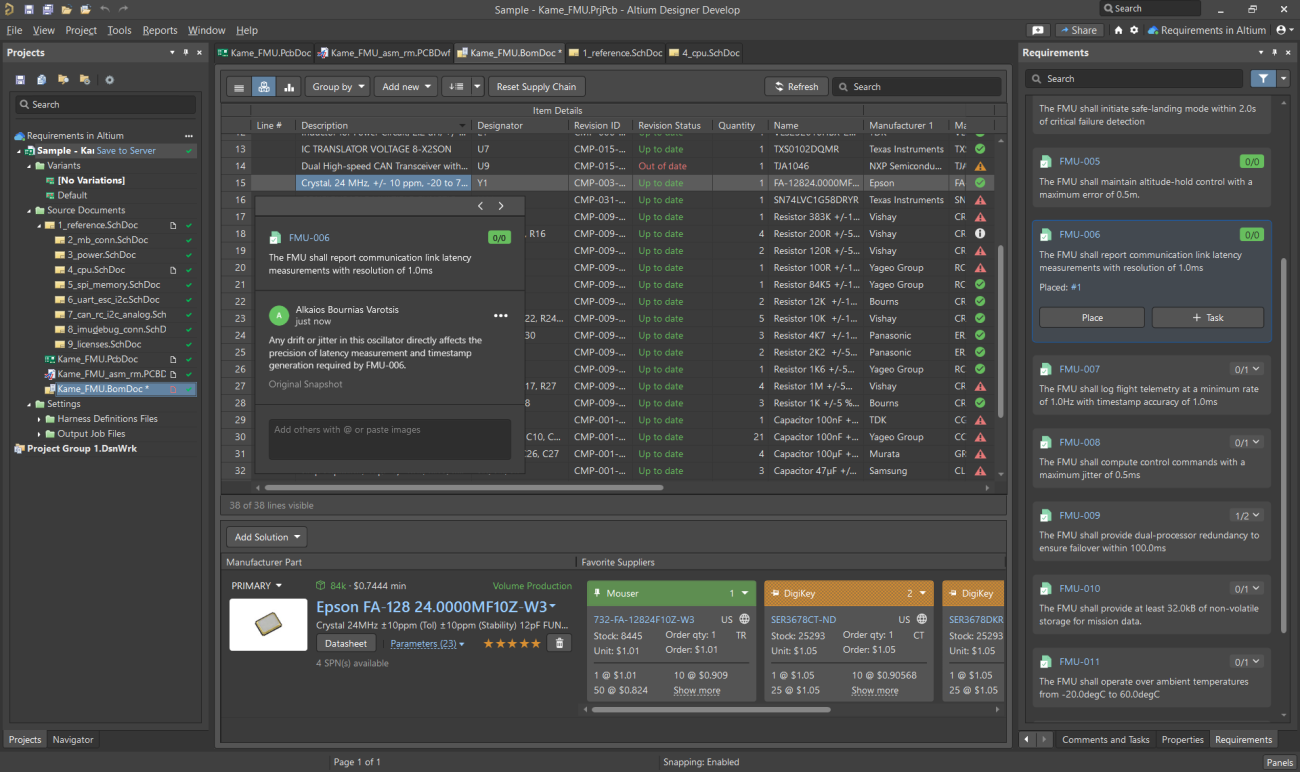

Work with Requirements Where Design Happens

Requirements are most effective when they are visible at the moment design decisions are made. Altium brings requirements directly into the electronics design environment, allowing engineers to view them alongside schematics, PCB layouts, and BOMs, and even link specific design decisions to requirements.

This direct connection ensures implementation always aligns with intent and helps prevent costly late-stage changes.

“We've found Altium's Requirements Portal to be a game-changer in our product development process.”

- Alf-Einar Løberg, Department Director, Sensio

By linking requirements to specific design elements, teams reduce ambiguity and design with confidence.

Collaborate Across Disciplines on Live Requirements

Modern hardware development depends on close collaboration between systems, electrical, mechanical, firmware, and UX teams. Altium’s Requirements & Systems Portal enables all stakeholders to work from the same live set of requirements, ensuring alignment even as projects evolve and notifying every engineer when a requirement is updated.

Changes are immediately visible across teams, reducing miscommunication and rework.

“The introduction of the Requirements & Systems Portal helps the UX-Group to always keep track of the fast changing requirements during the development process of our products.”

- Markus Kail, Tool Solution Architect, Ultratronik GmbH (UX-Gruppe)

Integrated reviews within Altium 365 and Altium Designer further shorten feedback cycles and improve decision quality.

Maintain Traceability Across the Entire Lifecycle

Full traceability — from requirements to design to verification — is critical for quality, compliance, and accountability. Altium’s Requirements Portal maintains these links automatically, making it easy to understand how every requirement is implemented and validated.

This continuous traceability supports both day-to-day decision-making and formal reviews.

“The structured approach to documenting requirements has streamlined our workflow, making it easier to manage and organize project specifications effectively.”

- Alf-Einar Løberg, Department Director, Sensio

Teams no longer need to manually reconstruct traceability at the end of a project — it’s built in from the start.

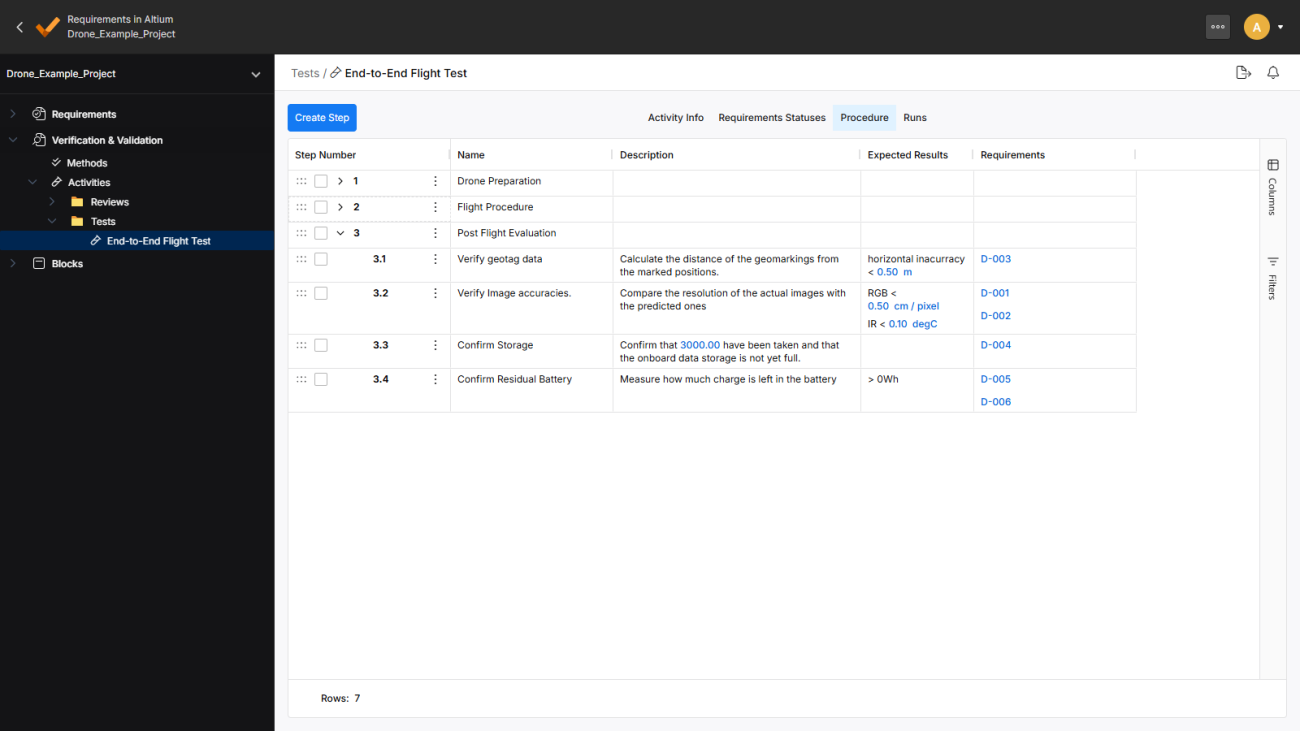

Plan and Track Verification with Confidence

Verification is no longer an afterthought. With integrated Verification & Validation capabilities, teams can define verification methods, plan test activities, and document results in a centralized system — fully linked back to requirements.

This structured approach ensures complete coverage and reduces the risk of missed or undocumented tests.

“The Verification & Validation module has proven invaluable, enabling us to create comprehensive test plans to verify all requirements while documenting test runs efficiently in a centralized system.”

- Alf-Einar Løberg, Department Director, Sensio

Verification progress and test coverage are visible in real time, helping teams identify gaps early and stay on track.

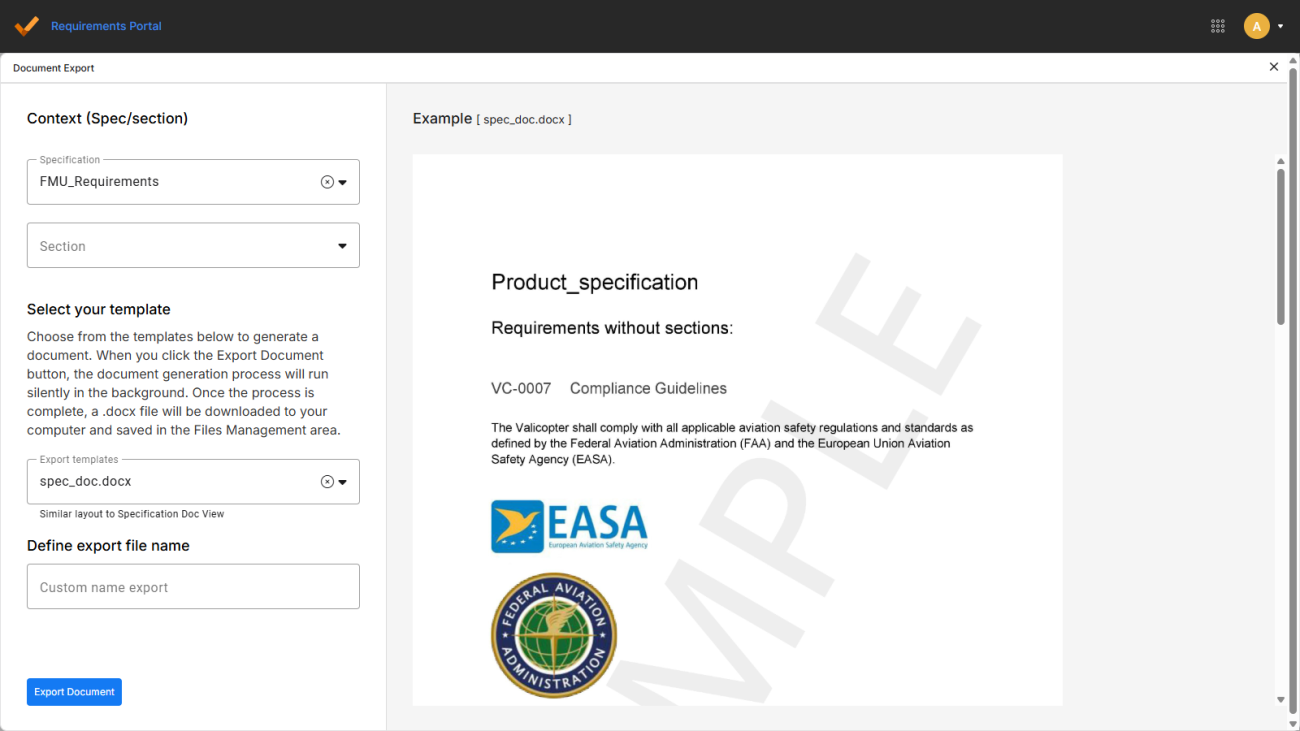

Generate Audit-Ready Documentation in Minutes

When it’s time for audits, handoffs, or compliance reviews, teams can generate traceability matrices and verification reports directly from live project data. This eliminates hours of manual document preparation and reduces the risk of outdated or inconsistent information.

“We have created user documentation that outlines the entire process — from defining stakeholder requirements to linking them with system requirements and then validating them through rigorous verification. Working with Requirements Portal is both productive and enjoyable!”

- Alf-Einar Løberg, Department Director, Sensio

Documentation becomes a natural output of the workflow — not a separate, last-minute effort.

Real ROI Through Reduced Rework and Downtime

For teams delivering multiple products each month, even small errors in requirements interpretation can lead to significant cost increases. By improving clarity, traceability, and verification, Altium helps teams protect both schedules and budgets.

“The ROI is FAST. We design three to five products a month, and reprints can easily increase our costs by 40%. Requirements Portal has saved us a lot of downtime in production. We basically got our value back in a couple of months.”

- Samuel Gosselin, Project Manager (R&D & CI), Memtronik Innovations

The impact is measurable: fewer respins, smoother production, and faster time to value.

Requirements Built for Modern Engineering Teams

Altium’s Requirements Portal enables teams to:

- Capture and manage requirements in one secure workspace

- Trace requirements directly to designs and verification

- Monitor progress and test coverage in real time

- Collaborate across disciplines with a shared source of truth

- Generate audit-ready documentation from live data

By connecting requirements, design, and verification in a single platform, Altium helps engineering teams bring complex products to life faster — with structure, clarity, and confidence.