The Power of Integration - Why Analysis Belongs to PCB Designers

As the complexity of our product designs increases each year, so do the requirements of our designs. And without proper analysis tools, PCB designers have little insight into potential flaws in their Power Distribution Network. We all largely rely on a dedicated simulation tool or prototype to identify issues, but these inefficient methods can eat up budgets and prolong development cycles. What if there was a way to make analysis accessible to the PCB at design time to get the insights we need about our design?

Making the Problem Clear to the

Post-design analysis through a prototype or specialist is the norm for designing an optimized, but these methods provide zero visibility for the PCB when he really needs it at design time. Analysis ran by the PCB instead of a dedicated Power Integrity Engineer has enormous advantages, including:

-

Immediate feedback to the allowing optimization through “what-if” scenarios.

-

Visual results displayed directly in the design that makes problems (and possible solutions) more intuitive to the .

-

Integrated design and analysis capabilities that eliminate the delay between and Power Integrity Engineer.

What You See Is What You Analyze

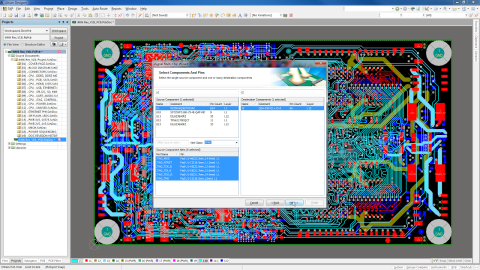

Designers can now have visibility over their network at design time with PDN Analyzer™ powered by CST®, a new extension for Altium Designer®. The intuitive, easy-to-use interface inside Altium provides the PCB with complete analysis data within their design, allowing engineers to:

-

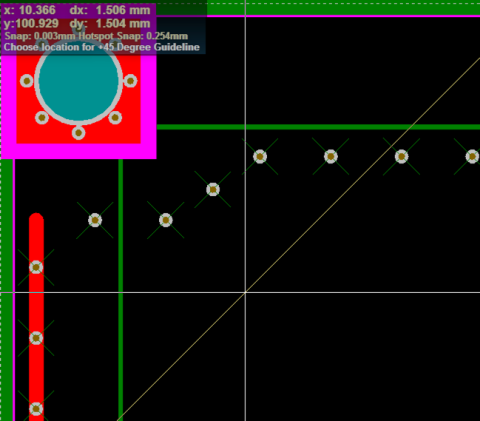

Optimize board layouts with the ability to read parameters and select valid nets and components directly in the design.

-

Enhance the accuracy of analysis data by eliminating any manual translation between the CAD and analysis tools.

-

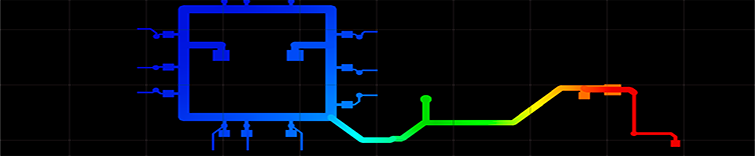

Easily detect issues with 3-D views that make complex issues more comprehensible and intuitive to resolve.

By having a unique insight into both the design and the requirements of the analysis tool, Altium can also disable analysis until the setup is valid. This can dramatically reduce troubleshooting time for complex designs as opposed to completing a 10-minute simulation only to receive a cryptic error message.

Enabling Analysis Not Otherwise Possible

With full control of the interface between the design and simulation engine, an integrated solution like powered by CST® can enable analysis that might otherwise be impossible. Altium creates “Virtual Components”, allowing you to connect a source between pads of two different devices (e.g., one for power and another for ground). This allows analysis to be done easily and efficiently in scenarios that might have proven difficult, if not impossible, with other methods. For example, linear regulators typically don’t have a dedicated ground pin (they are essentially current limiters), so the ground connection often has to be made to the source of the linear regulator for accurate analysis.

Another example of an integrated solution’s unique abilities is a case where the source and load connect to different nets with power being delivered through a switch, fuse, resistor, etc... With the intimate knowledge of the design, can lead the user through automatically constructing the proper path from source to load, including any passive interconnecting. Compare this with the complexity required for a non-integrated simulation tool and the use of an in-design analysis solution seems like the obvious choice.

What's the Power Integrity Specialist to Do?

Of course, there are limits to the complexity a tool can accommodate while remaining usable by the non-expert, and occasionally Power Integrity Engineers will still be necessary to handle setting limits and solving many power and signal integrity challenges.

A reasonable analogy is having access to blood-sugar measurements. There are devices that allow the consumer to bring advanced capability into their house and respond to most situations, but that doesn’t eliminate the need for doctors. Rather, it can free the doctor considerably while providing better care for the patient, enabling them to quickly and easily monitor their own health and take appropriate action.

The same principles above hold true for analysis. By providing PCB designers with analysis tools at design time, a large majority of issues can be resolved without requiring a simulation specialist. And when the complex, heavy-lifting simulation is required, Power Integrity Engineers will be there to lead the way.

Making Analysis Accessible at Design Time

Coupling analysis capabilities with your design tools enable the designer to easily identify and preemptively solve issues during the board layout process. And with powerful analysis tools at their disposal, PCB designers can easily optimize their design time.

Interested to see how an integrated analysis solution can help you to enhance the development of your products? Register now for a free trial for today.

Check out Altium in action...

Powerful PCB Design

Back

Back