How to Read PCB Assembly Drawings

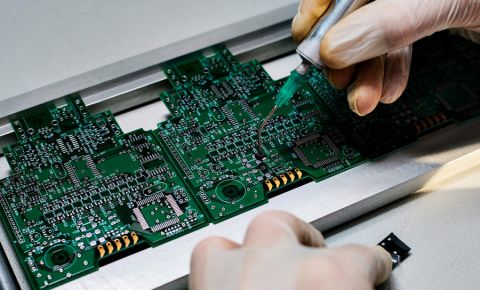

PCB assembly drawings give us the information we need to get a board assembled correctly. But when we say assembly, it does not just refer to the soldering process. Of course, soldering information should be included in a PCB assembly drawing, but this is not the end of the information that should be in these documents. A full assembly drawing is not just about assembling the PCB, and is also used for product assembly.

If this is where your designs need to go, then this article will guide you on reading an assembly drawing for a PCB and a larger product. Includes plenty of examples in Altium Draftsman, the fastest and simplest tool for creating PCB fabrication and assembly drawings.

What Drawings Tell Us About PCBAs

If you want to know how to build a specific PCBA, then you need its assembly drawing. The assembly drawing provides the basic instructions needed to build a PCBA from a bare board and components. The point of the assembly drawing is to act as a master reference for the final product, which will include some important information:

- The process, such as assembly requirements, solder paste, and non-standard testing

- Handling and packaging, including bag and tag, moisture safety requirements, or ESD safety requirements

- The look and feel, which is communicated through a 3D perspective view of the assembly from your CAD software

- Sub-components, like cabling, fasteners, custom harnesses, or the enclosure.

All of these can be specified in the assembly drawing both graphically and with assembly notes. The graphics and notes in the assembly tell us a lot of important information about the process and can help answer some quick questions that would normally delay assembly procedures.

PCB Assembly Notes

The assembly notes are where the designer will specify basic assembly requirements, which may include solder paste formulation and type, coating or adhesive requirements, handling procedures, and packaging requirements for the assemblies. More detailed assembly notes may specify routine on-target components, and assembly of any mechanical elements.

The easiest way to get a sense of the contents of PCB assembly notes is to look at an example. Take a look at the assembly notes example below, which specifies several requirements in the assembly.

|

ASSEMBLY NOTES Board Name: Example Board Rev: A 1. Assemble in accordance with IPC-A-610, current revision, Class 2. 2. Solder electrical connections per latest revision of IPC J-STD-001. 3. This assembly contains ESD sensitive components. Handle per ANSI/ESD S20.20. 4. RoHS compliance required: Yes. 5. Mark with current assembly revision. 6. Mount components with polarity and orientation as shown on component designators/silkscreen. |

You may also want to add notes about any International Traffic in Arms Regulations (ITAR) compliance requirements that may apply to the final product. Notes may also include how the product responds to IPC classifications for workmanship and reliability.

The assembly notes listed above are typical and are well understood by fabrication houses and assemblers. To understand these notes, it means you look up the technical points in a standards document.

2D and 3D Assembly Views

Assembly views are also commonly included in PCB assembly drawings. These are included as a reference so that assemblers can spot when a mistake has been made in placement or component orientation. They are also included so that the designer can add special assembly instructions for specific components using markup and callouts.

The 2D assembly view is created from the assembly layers in your PCB footprints. A designer can also draw in the assembly layer in the PCB layout. Drawings can then be generated for the top and bottom side of the board from exports of the assembly layers. However, with newer drawing generation tools, DXF exports are not needed and the assembly can be created inside your CAD software.

3D views must be generated from an isometric or orthographic projection of a 3D model or the full PCB assembly. Today, most CAD systems support this as long as 3D models are included for your PCB components. You can also create this manually from a STEP model export for your PCB layout using MCAD software.

These 2D and 3D views are not good for making measurements. Reference designators and silkscreen items can be placed into the 2D view for verification of placement. It is also a good idea to include polarity indicators (e.g., on electrolytic capacitors) in the assembly layer for each component, and these will appear in the 2D assembly view. This will give a visual way to verify component orientation. This view is used in a number of tasks, from manual inspection to rework and verification in SMT programming, particularly when bare boards are not available or when polarity indicators are missing from the PCB silkscreen layers.

Wiring, Cables, and Enclosures

PCBs don't exist in a vacuum, they are always part of a larger product with an enclosure and cabling or wiring. That means an assembly drawing does not have to confine itself to PCB assembly. Assembly steps for cabling, wires, and the enclosure can be incorporated into the PCB assembly drawing. For product assembly drawings with cabling and enclosures, the exploded view is preferred as it shows each component and where it connects into the assembly. Callouts are also used for special instructions in the assembly process.

An example of a dimensioned assembly drawing for a wiring harness is shown below. The details include wiring runs, branches, and connector part numbers.

In addition, a wiring table is very helpful as it will reflect the information from your harness design tool. A wiring table pulls items from your harness BOM, the connector reference designators/pin numbers, and part numbers for the connectors to aid in assembly of a custom harness. Additional information can be included, like wire gauge, color, and length.

Multi-board assemblies can be shown in a PCB assembly drawing, which would include all the boards in the product assembled into perspective views. Multi-board assembly drawings can show a project-level view as well as assembly views for each of the boards in a single document. This type of compiled assembly document is necessary for complete product assembly and packaging on a single line. Make sure you discuss the required assembly steps with your team to better understand what they will expect from an assembly drawing.

Focus on What Assemblers Need

Assemblers see a lot of assembly drawings in different formats and styles. However, there is a universal language embedded within assembly drawings. If you can understand what the diagrams and notes are saying, you'll better understand how to create assembly drawings and how the process steps impact your assemblies. To help you quickly create assembly drawings, make sure to check out Altium Draftsman, the fastest tool for generating drawings for PCB manufacturing and product assembly.

Whether you need to build reliable power electronics or advanced digital systems, use Altium’s complete set of PCB design features and world-class CAD tools. Altium provides the world’s premier electronic product development platform, complete with the industry’s best PCB design tools and cross-disciplinary collaboration features for advanced design teams. Contact an expert at Altium today!