Conquering Your Design Demands with USB Type-C

The last thing you want is getting your power demands balance wrong on your electronic design. Too little voltage and your device starves; too much voltage and you’re left with smoke signals for help as caps pop like the Fourth of July. Not to mention that the complications you run into when your device has varying voltage requirements when operating in different states. The increased usage of embedded sensors has made constant data acquisition simple, but increasing data transmission and reducing power consumption at the same time has proven difficult. Wouldn’t it be great to have a combined solution that everyone could use?

DATA TRANSMISSION

Data transmission is often necessary for shared data analysis in a more powerful system, and often it uses wireless technology. Electronic components like cellular phones provide a prototypical example for the trend between shared data across devices. The cell phone acts as a centralized device to handle data processing for connected accessories such as smart watches, headphones, and lighting systems. However, wireless connection and control of peripherals places a heavy strain on the power consumption of the phone.

Data transmission is always around us

Wired interfaces meet all the necessary demands with the added benefit of lower power consumption than wireless interfaces, and high USB hub pcb board production demonstrates wired connections are still popular. Understanding traditional methods has laid the groundwork for the advancement of new technology for data transmission: PCB Design for USB Type-C.

HISTORY OF USB CONNECTIVITY

Until the late 90’s, data transmission and battery charging was almost exclusively handled with wired connections. Different cable standards have evolved to fit varying utilizations, but the core applications have remained the same: data transmission, displays, and power. Universal Serial Bus, commonly called USB, has provided an inexpensive, versatile, and open distribution solution for the last twenty years. USB Type-A and B are the most prominent wired data transmission cables available throughout the world.

Evolution of Data Transmission

The inexpensive and readily accessible nature of USB Type-A and B has attributed to the propagation of the standard across the industry. They are so prolific that even the majority of proprietary cables utilize USB Type-A interfaces on at least one end. USB development has produced a variety of types throughout its inception in the mid-90s. USB versions define specifications for speed and functionality. Meanwhile, the different USB types account for the differences in shape and construction, such as the wiring. Understanding the differences in versions and types is essential to understanding functionality and structure of the cables and the development of the USB Type-C cable. Greater knowledge of the standards will inform you on proper design choices necessary to integrate functionality into your design.

USB Type-A

- Flat, rectangular end.

- Male USB Type-A connector is the standard connector to host devices.

- Female USB Type-A connectors create ports that can be found in the majority of devices that can host and connect to peripherals.

- Retained the same construction over the years allowing communication between any Type-A port regardless of USB version.

- Type-A host and peripherals do not require the same USB version to function together.

- The compatibility of the port along different versions attributes to its stability and longevity.

USB Type-B

- The common connector seen for peripherals.

- Male Type-B ports are typically used for the cables while the female port connectors are embedded within the peripheral.

- There have been a number of variations on USB Type-B connectors as form factors of peripheral devices have continued to shrink throughout the years.

- The mini-B USB is slowly becoming obsolete as a result of the proliferation of micro-B.

- The micro-B USB is the de facto connector utilized in modern mobile technology such as phones, cameras, and tablets.

- Unlike Type-A varieties, the USB Type-B variations differ greatly in shape and appearance.

- The most common USB Type-B connectors are standard-B, mini-B, and micro-B.

- The standard and micro plugs have updated designs to operate with Version 3.0.

Proprietary Type USB

There are several proprietary USB cables that have been created to replace USB Type-B connectors. However, these cables still utilize USB Type-A connectors paired with proprietary connectors. These types of connections can be seen for many media players. The problem with these cables is their limited implementation and usage.

USB VERSIONS

The USB standard has progressed over the years through the implementation of versions. Each version enabled faster data transmission speeds and battery charging of electronic components while maintaining signal integrity. The first consumer USB version 1.1 had maximum output of 2.5V and 500 milliamps of power with 12 Mbps data transmission. USB 2.0 affords more current with 1.8 Amps while still producing 2.5V. The maximum speed is 480 Mbps in Hi-Speed mode or 12 Mbps in Full-Speed mode. USB 3.0 ports increased the maximum voltage to 5 volts while still providing appropriate power to 2.0 devices. The maximum speed of version 3.0 is 5 Gbps--a superspeed USB by comparison. USB 3.0 ports and connectors can be identified by their blue coloring. The latest USB Version 3.1 will be discussed later.

Usb versions table

SIMPLIFIED CONNECTIVITY: USB TYPE-C

While USB Type-A, B, and other proprietary cables have provided our data transmission needs for several decades, they have failed to take into account other needs like display outputs and power delivery. USB Type-C interface port connectors, regularly found in new electronic components and USB hub PCB designs, combine the benefits of superspeed USB data transmission, display outputs, and power delivery with the ability to fully harness all USB version specifications. The most current version, USB 3.1, was released in July of 2013 and provides speeds up to 10 Gbps. In addition, the ports can produce 15 watts passively or 5 amps at 20 Volts of power utilizing the latest USB Power Delivery specification allowing them to power a greater number of technologies. There are three USB Power Delivery specifications for different applications. The first power delivery specification allows devices to utilize up to 2 amps at 5V. The two other power delivery specifications allow drawing up to 5 amps at either 12V or 20V.

Artist renderings of USB receptacles and cables

The USB Type-C port is similar in size to the micro-b 2.0 ports allowing it to take up minimal space in designs with small form factors, but with the versatility to power large mechanisms. The type-C connector has been designed to connect to either host or peripherals removing the need for the type-A interface. However, type-A connectors and converters are used to provide backwards compatibility. Future type-C cables will have type-C connectors on both ends providing an omnidirectional design.

The pin setup within each connector also makes the connector reversible, so that you never have to deal with plugging your cables in “the right way.” In the future, these cables will provide a method that can transmit enough power to run laptops and other larger gadgets. Utilizing USB Type-C will allow devices to transmit data and receive power simultaneously from a single port. This can be used for external hard drives, displays, and any system that can operate under the power delivery specifications. The Type-C USB also provides bi-directional power allowing the host to charge a peripheral or vice versa, if the need arises.

CABLE CONSTRUCTION

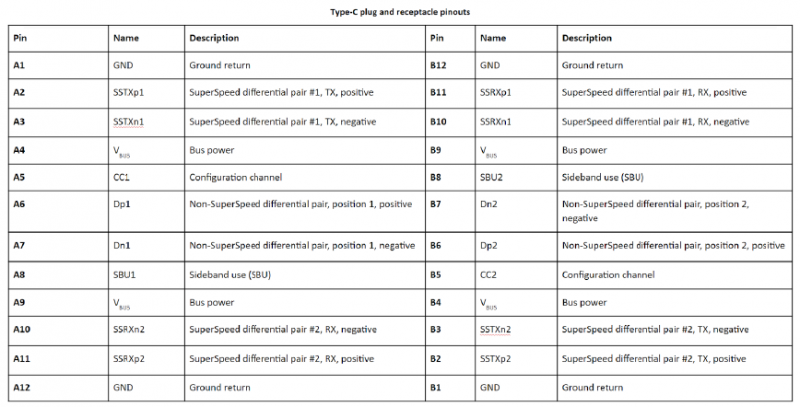

USB Type-C Pinout

The USB Type-C 24 pinout is rotationally symmetrical which is why the connector can be plugged in either way. The 24 pins can be categorized into five types: power and ground pairs, data paths, USB 2.0 differential pairs, sideband pins for Alternate Mode use, and plug configuration pins.

There are two pairs of ground pins and two pairs of power pins called Vbus. The data paths consist of four differential pairs that can be used for high speed data transmission under specifications for USB Version 3.1. In addition, two differential pairs for USB 2.0 functionality that operate a pair at a time and the sideband pins for Alternate Mode. Lastly, the plug configuration pins or CC pins allow the host to detect cable orientation in order to properly implement the USB Power Delivery specification.

Alternate mode allows third party configuration of many of the pins to create custom implementations. Please refer to this link for more detailed information about USB Power Delivery Specifications from the USB Implementers Forum.

USB Type-C Pinout Table

CABLE COMPATIBILITY

As USB Type-C connectors gain prevalence, dual USB Type-C connectors will become more common. Since USB Type-C is backwards compatible, even a pure USB Type-C connector can be utilized with any USB Version 2.0 and up with use of an adapter to operate Type-C products with existing USB ports. The design of USB Type-C is said to be future proof as the development of future USB Versions will utilize the structure of the Type-C connector. The versatility of the USB Type-C will continue to gain prominence as it simplifies our designs and the way our devices communicate. Unifying data and power transmission to a single port will open up design real estate for other components and design aspects.

While the USB Type-C connectors can leverage USB PD specifications for power delivery, in the words of Uncle Ben, “with great power comes great responsibility.” Many cables are being produced to capitalize on the new market for USB Type-C connectors and some of these cables do not meet the full requirements for power delivery. It is important to design products for general use as opposed to a specific use case. There are products using USB Type-C ports that ship with cables that operate perfectly for their application, but would harm another device. It can be difficult when designing not only taking into account the needs of your product, but the other products that your device will be interacting with. Designing your products for sustainability and interconnectivity is a responsibility that shouldn’t be taken lightly. Careful study of the USB Specification should precede the development of your designs.

EXAMPLE PIN CONFIGURATIONS

Full-Featured Cable Reconfigurable Pins

Direct Connect Applications Reconfigurable Pins

USB TYPE-C: HOST AND GUEST OF HONOR

The transition from the traditional connectors will take time, but the potential of USB Type-C interface is clear: board real estate previously occupied by multiple connectors is freed for layout and the array of specialized cables will consolidate to a multi-use cable for operation. The open standard allows everyone in the industry to meet their power and data transmission with a single connector and cable type.

Additionally, increased functionality and configurability allows every industry sector to utilize the same connection system increasing compatibility between technologies. Devices will not suffer the restriction of being a dedicated host removing the dichotomy of acting as a host and peripheral simplifying communication between devices and enabling bidirectional communication. Products can be designed with the intent to switch from host to peripheral in order to create a varied ecosystem of connected mechanisms. If you’re not already considering a PCB design for USB Type-C interface, now is the perfect time to start.