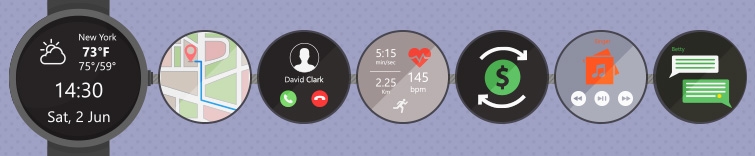

Electronification of the World, One Wearable at a Time

As the world of electronic manufacturing shifts into the eras of Industry 4.0, IoT, and Big Data, it’s becoming more important than ever for companies to embrace software platforms to remain competitive. This process has never been more challenging when you factor in other competing goals including reducing time to market, increasing quality and efficiency, and optimizing your entire value chain. What’s driving this transformation where today’s manufacturing and mechanically-focused companies are becoming high-tech-focused?

Shifting Focus

A perfect example of a company that has recently undergone electronification is Nike, which has extended its footprint into the high-tech world through its wearable technology. Over the years, it has been amazing to observe the world’s largest sports gear company transform into a company embracing electronic designs and intelligently connected products.

This couldn’t have been an easy process for Nike, as it required them to deal with new regulatory environments, supply chain realignment, and new crisis management guidelines all the while adopting an entirely new stream of electronic parts and inventory. So how exactly did they do it?

Bridging the Gap

Nike had to do something that many companies struggle with - bridging the gap between their electronic and mechanical domains. This process has led many companies into uncharted territories, requiring them to develop new solutions that allow for cross-domain collaboration, all while being able to manage an entire product lifecycle. A transformative journey of this scope would need to include the following elements to be successful:

-

Seamless design collaboration. This is a must-have for teams that need to tackle a product development process in parallel. Adding tools for communication into the design process allows design teams to work on products simultaneously with required documentation and visibility for any changes made.

-

Transparent revision management. This element is critical to ensure that everyone is in sync on a project while allowing only approved designs to be used (or). When changes are made, every stakeholder knows about it, and a notification system can enable teams to proactively handle new changes.

-

Flexible lifecycle state management. Whether a company is already designing complex systems or is ramping up to deal with electronic parts (such as Nike), they both need a centralized way to access and design with approved components. A lifecycle states management system does just that, providing the visibility a team needs to select the right parts at design time.

-

Rich supply chain data. Your project can’t be isolated from the partners you depend on, and visibility into your supply chain can save you from making costly mistakes down the road. With an established ERP system, it’s easy to get real-time access to distributors and your internal database so you can make the most informed part selections with pricing and availability.

With the four elements outlined above, a company like Nike will be well on their way to bridging the gap between their electronic and mechanical domains. Of course, at the end of the day, delivering successful products to market is about so much more than just hard work innovation, and dedication. It also requires knowing when and how to adapt to new shifts in the world of electronic technologies and opportunities.